Nissan Maxima Service and Repair Manual: Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

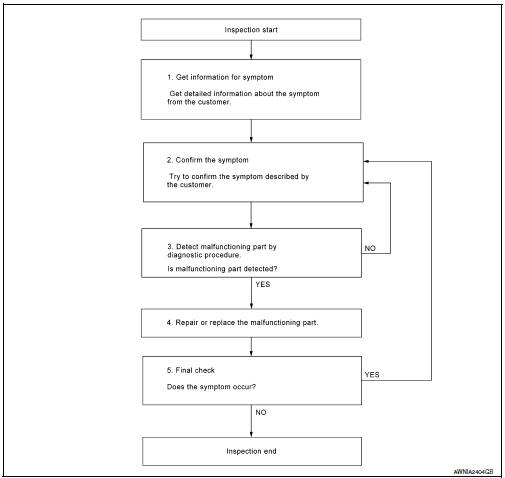

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get detailed information from the customer about the symptom (the condition and the environment when the incident/malfunction occurred).

2.CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer. Verify relation between the symptom and the condition when the symptom is detected. Refer to SE-51, "Symptom Table".

3.DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the system.

4.REPAIR OR REPLACE THE MALFUNCTIONING PART

- Repair or replace the malfunctioning part.

- Reconnect parts or connectors disconnected during Diagnostic Procedure.

5.FINAL CHECK

Refer to confirmed symptom in step 2, and make sure that the symptom is not detected.

Seat

Seat

...

System description

System description

CLIMATE CONTROLLED SEAT SYSTEM

System Diagram

System Description

The climate controlled seat system is controlled by the climate

controlled seat control unit.

Operation of the climate co ...

Other materials:

Chassis & body maintenance

Abbreviations: I = Inspect and correct or replace as necessary, R =

Replace,

NOTE:

Maintenance items with " " should be performed more frequently according

to "Maintenance under severe driving conditions".

(1) If towing a trailer, using a camper or a car-top carrier or driving on ro ...

P0703 brake switch B

Description

BCM detects ON/OFF state of the stop lamp switch and transmits the data to

the TCM via CAN communication

by converting the data to a signal.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION: Always drive vehicle at a safe speed.

NOTE: Immediately after perform ...

Symptom diagnosis

ADP SYSTEM SYMPTOMS

Symptom Table

SYMPTOM 1

SYMPTOM 2

SYMPTOM 3

SYMPTOM 4

SYMPTOM 5

NORMAL OPERATING CONDITION

Description

The following symptoms are normal operations, and they do not indicate a

malfunction.

...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0072