Nissan Maxima Service and Repair Manual: Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

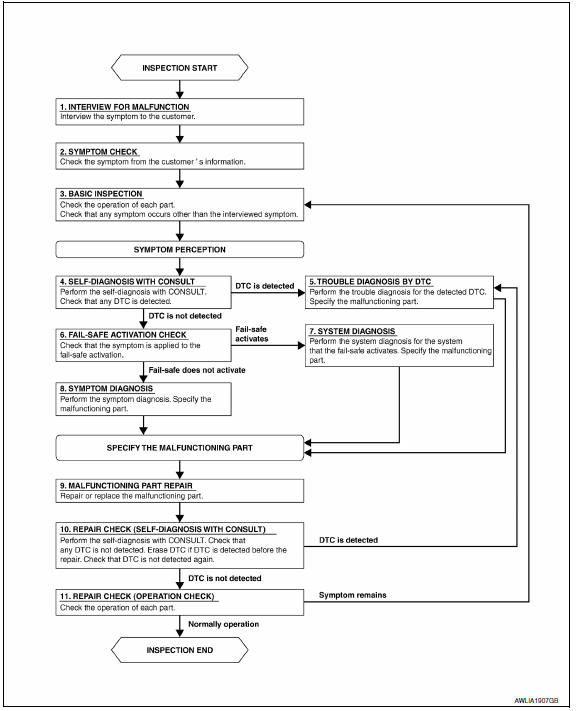

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Find out what the customer's concerns are.

2.SYMPTOM CHECK

Verify the symptom from the customer's information.

3.BASIC INSPECTION

Check the operation of each part. Check that any concerns occur other than those mentioned in the customer interview.

4.SELF-DIAGNOSIS WITH CONSULT

Perform the self-diagnosis with CONSULT. Check that any DTC is detected.

5.TROUBLE DIAGNOSIS BY DTC

Perform the trouble diagnosis for the detected DTC. Specify the malfunctioning part.

6.FAIL-SAFE ACTIVATION CHECK

Determine if the customer's concern is related to fail-safe activation.

7.SYSTEM DIAGNOSIS

Perform the system diagnosis for the system in which the fail-safe activates. Specify the malfunctioning part.

8.SYMPTOM DIAGNOSIS

Perform the symptom diagnosis. Refer to INL-81, "Symptom Table". Specify the malfunctioning part.

9.MALFUNCTION PART REPAIR

Repair or replace the malfunctioning part.

10.REPAIR CHECK (SELF-DIAGNOSIS WITH CONSULT)

Perform the self-diagnosis with CONSULT. Verify that no DTCs are detected. Erase all DTCs detected prior to the repair. Verify that DTC is not detected again.

11.REPAIR CHECK (OPERATION CHECK)

Check the operation of each part.

Other materials:

Horizontal synchronizing (HP) signal circuit

Description

In composite image (AUX image, camera image), transmit the vertical

synchronizing (VP) signal and horizontal synchronizing (HP) signal from

display unit to AV control unit so as to synchronize the RGB images displayed

with AV control unit such as the image quality adjusting menu, ...

Vehicle Dynamic Control (VDC) off switch

The vehicle should be driven with the VDC system

on for most driving conditions.

If the vehicle is stuck in mud or snow, the VDC

system reduces the engine output to reduce

wheel spin. The engine speed will be reduced

even if the accelerator is depressed to the floor. If

maximum engine po ...

Diagnosis and repair workflow

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1. GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the

condition and the environment when

the incident/malfunction occurred).

2. CHECK DTC

Check DTC.

Perform the following procedure if DTC is ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0053