Nissan Maxima Service and Repair Manual: Magnet clutch

Description

SYSTEM DESCRIPTION

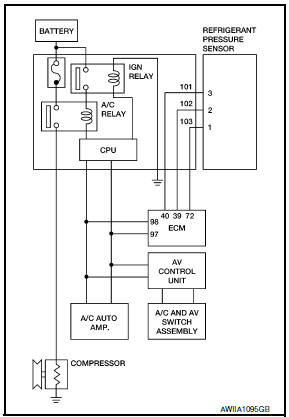

A/C auto amp. controls A/C compressor operation by ambient temperature and signal from ECM.

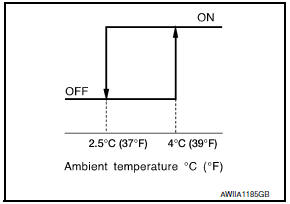

Low Temperature Protection Control A/C auto amp. will turn the A/C compressor ON or OFF as determined by a signal detected by ambient sensor.

When ambient temperature is greater than 4C (39F), the A/C compressor turns ON. The A/C compressor turns OFF when ambient temperature is less than 2.5C (37F).

Component Function Check

1.FUNCTION INSPECTIONS

- Press AUTO switch. AUTO is indicated on the display.

- Press the A/C switch.

- Check that the indicator of the A/C switch turns on. Check visually and by sound that the compressor is operating. (The discharge air temperature or fan speed varies depending on the ambient temperature, invehicle temperature, and temperature setting.)

- Press the A/C switch again.

- Check that the indicator of the A/C switch turns OFF. Check visually and by sound that the compressor stops.

Diagnosis Procedure

SYMPTOM: Magnet clutch does not engage when A/C switch is ON.

1.INSPECTION IN AUTO ACTIVE TEST MODE

Perform "AUTO ACTIVE TEST".

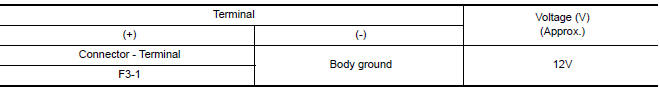

2.CHECK POWER SUPPLY FOR A/C COMPRESSOR

- Turn ignition switch OFF.

- Disconnect A/C compressor connector.

- Start engine and press A/C switch.

- Check voltage between A/C compressor harness connector F3 terminal 1 and ground

3.CHECK FUSE

Check 10A fuse (No. 41).

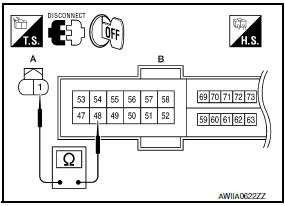

4.CHECK CIRCUIT CONTINUITY BETWEEN A/C RELAY IN IPDM E/R AND A/C COMPRESSOR

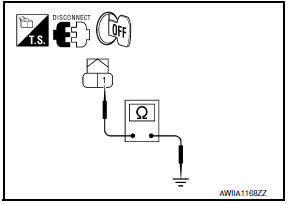

- Turn ignition switch OFF.

- Disconnect IPDM E/R connector F10 and A/C compressor connector F3.

- Check continuity between A/C compressor harness connector F3 (A) terminal 1 and IPDM E/R harness connector F10 (B) terminal 48.

1 - 48: Continuity should exist.

5.CHECK A/C COMPRESSOR CIRCUIT FOR SHORT

Check continuity between A/C compressor harness connector F3 terminal 1 and ground.

1 - Ground: Continuity should not exist.

6.CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT

- Using CONSULT, perform "SELF-DIAGNOSIS RESULTS" of HVAC.

- Check if any DTC No. is displayed in the self-diagnosis results.

NOTE: If DTC is displayed along with DTC U1000 or U1010, first diagnose the DTC U1000 or U1010.

7.CHECK A/C AUTO AMP. INPUT SIGNAL

Using CONSULT, check "On/Off" of "COMP REQ SIG" and "FAN REQ SIG" in "DATA MONITOR" of HVAC.

A/C SWITCH ON: COMP REQ SIG On

A/C SWITCH OFF: COMP REQ SIG Off

FAN CONTROL DIAL ON: FAN REQ SIG On

FAN CONTROL DIAL OFF: FAN REQ SIG Off

8.CHECK REFRIGERANT PRESSURE SENSOR

Check refrigerant pressure sensor.

Blower motor

Blower motor

Description

COMPONENT DESCRIPTION

Brush-less Motor

The blower motor utilizes a brush-less motor with a rotating magnet.

Quietness is improved over previous motors where the brush was

the point ...

Power supply and ground circuit

Power supply and ground circuit

A/C AUTO AMP.

A/C AUTO AMP.: Description

COMPONENT DESCRIPTION

A/C Auto Amp. (Air Conditioner Automatic Amplifier)

The A/C auto amp. (1) has a built-in microcomputer that processes

information se ...

Other materials:

Display unit

Reference Value

TERMINAL LAYOUT

PHYSICAL VALUES

BOSE SPEAKER AMP

Reference Value

TERMINAL LAYOUT

PHYSICAL VALUES

...

B2098 ignition relay on stuck

DTC Logic

DTC DETECTION LOGIC

1.PERFORM DTC CONFIRMATION PROCEDURE

Turn the power supply position to start under the following

conditions and wait for at least 1 second.

CVT selector lever is in the P (Park) or N (Neutral) position.

Depress the brake pedal

Check "Self-diag ...

Diagnosis and repair work flow

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom

(the condition and the environment

when the incident/malfunction occurred) using the "Diagnostic Work Sheet".

(Refer to EC-12, "Diagnostic ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0102