Nissan Maxima Service and Repair Manual: Power supply and ground circuit

A/C AUTO AMP.

A/C AUTO AMP.: Description

COMPONENT DESCRIPTION

A/C Auto Amp. (Air Conditioner Automatic Amplifier) The A/C auto amp. (1) has a built-in microcomputer that processes information sent from various sensors needed for air conditioner operation. The air mix door motor(s), the mode door motor, the intake door motor, the blower motor and the compressor are then controlled.

When the various switches and temperature control dial are operated, data is input to the A/C auto amp. from the AV control unit using CAN communication.

The A/C auto amp. is operated with control mechanisms. Signals from various switches and Potentio Temperature Control (PTC) are directly entered into the A/C auto amp.

Power Supply and Ground Circuit for A/C Auto Amp.

A/C AUTO AMP.: Component Function Check

1.CHECK OPERATION

- Press the AUTO switch, and then check that "AUTO" is shown on the display.

- Operate the temperature control dial (driver side). Check that the fan speed or outlet changes. (The discharge air temperature or fan speed varies depending on the ambient temperature, in-vehicle temperature, and temperature setting.)

A/C AUTO AMP.: Diagnosis Procedure

1.CHECK FOR AUDIO DTCS WITH CONSULT

Using CONSULT, perform "SELF-DIAGNOSIS RESULTS" of MULTI AV.

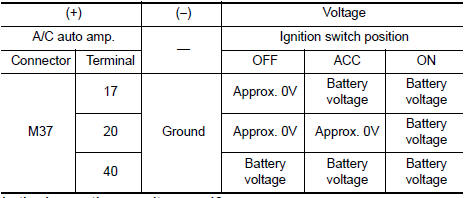

2.CHECK A/C AUTO AMP. POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect the A/C auto amp. connector.

- Turn ignition switch ON.

- Check voltage between A/C auto amp. harness connector M37 terminal 17, 20, 40 and ground.

3.CHECK FUSE

Check 10A fuses [Nos. 3, 6 and 17, located in the fuse block (J/B)].

4.CHECK A/C AUTO AMP. GROUND CIRCUIT

- Turn ignition switch OFF.

- Check continuity between A/C auto amp. harness connector M37 terminals 19, 39 and ground.

19, 39 - Ground: Continuity should exist.

A/C AND AV SWITCH ASSEMBLY

A/C AND AV SWITCH ASSEMBLY: Component Function Check

1.CHECK OPERATION

- Press the AUTO switch, and then check that "AUTO" is shown on the display.

- Operate the temperature control dial (driver side). Check that the fan speed or outlet changes. (The discharge air temperature or fan speed varies depending on the ambient temperature, in-vehicle temperature, and temperature setting.)

A/C AND AV SWITCH ASSEMBLY: Diagnosis Procedure

1.CHECK FOR AUDIO DTCS WITH CONSULT

Using CONSULT, perform "SELF-DIAGNOSIS RESULTS" of MULTI AV.

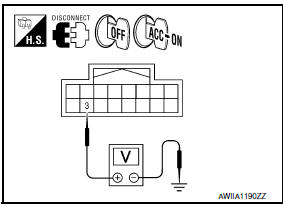

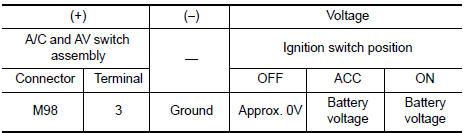

2.CHECK A/C AND AV SWITCH ASSEMBLY POWER SUPPLY

- Disconnect the A/C and AV switch assembly connector.

- Check voltage between A/C and AV switch assembly harness connector M98 terminal 3 and ground.

3.CHECK FUSE

Check 10A fuse [No.17, located in the fuse block (J/B)].

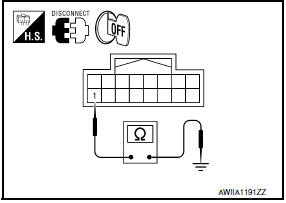

4.CHECK A/C AND AV SWITCH ASSEMBLY GROUND CIRCUIT

- Turn ignition switch OFF.

- Check continuity between A/C and AV switch assembly harness connector M98 terminal 1 and ground.

1 - Ground: Continuity should exist.

Magnet clutch

Magnet clutch

Description

SYSTEM DESCRIPTION

A/C auto amp. controls A/C compressor operation by ambient temperature and

signal from ECM.

Low Temperature Protection Control

A/C auto amp. will turn the A/ ...

ECU diagnosis information

ECU diagnosis information

A/C AUTO AMP

Reference Value

VALUES ON THE DIAGNOSIS TOOL

CONSULT MONITOR ITEM

A/C AUTO AMP. HARNESS CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUES FOR A/C AUTO AMP.

Fa ...

Other materials:

Sunroof unit assembly

Inspection and Adjustment

INSPECTION

Wind Deflector

Open glass lid assembly fully.

Visually check for proper installation, damaged/deteriorated

components, or foreign objects within mechanism.

Correct as required for

smooth operation.

Check for grease at the wind deflector arm ( ...

Periodic maintenance

FOR USA AND CANADA

FOR USA AND CANADA : Introduction of Periodic Maintenance

The following tables show the normal maintenance schedule. Depending upon

weather and atmospheric conditions,

varying road surfaces, individual driving habits and vehicle usage, additional

or more frequent maintenan ...

Multifunction switch

Removal and Installation

REMOVAL

Remove cluster lid D. Refer to IP-18, "Removal and Installation".

Remove the four multifunction switch screws (A) and the

multifunction

switch (2) from cluster lid D (1).

: Metal clip

INSTALLATION

Installation is in the reverse order ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0108