Nissan Maxima Service and Repair Manual: Magnet clutch control system

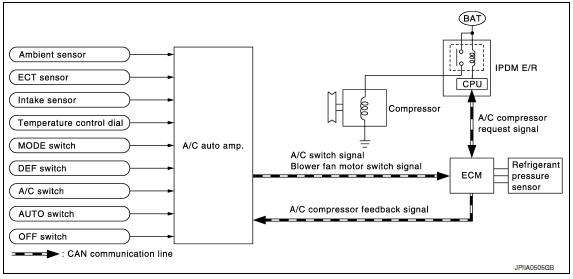

System Diagram

System Description

The A/C auto amp. controls A/C compressor operation by ambient temperature, intake air temperature and signal from ECM.

SYSTEM OPERATION

When the A/C switch, the AUTO switch, or the DEF switch is pressed, or when shifting mode position to D/F, the A/C auto amp. transmits the A/C switch signal and blower fan motor switch signal to the ECM, via CAN communication.

ECM judges whether the A/C compressor can be turned ON, based on each sensor status (refrigerant-pressure sensor signal, throttle angle, etc.). If the ECM judges that the A/C compressor can be turned ON, it sends A/C compressor request signal to the IPDM E/R, via CAN communication.

Upon receipt of A/C compressor request signal from the ECM, the IPDM E/R turns the A/C relay ON to operate the A/C compressor.

When sending A/C compressor request signal to the IPDM E/R via CAN communication line, the ECM simultaneously sends A/C compressor feedback signal to A/C auto amp. via CAN communication line.

The ECM sends A/C compressor feedback signal to A/C auto amp., then, uses input A/C compressor feedback signal to control air inlet.

A/C compressor Protection Control

The ECM makes the A/C relay turn OFF and stops the A/C compressor when pressure on the high-pressure side, detected by the refrigerant pressure sensor, is over approximately 3,119 kPa (31.8 kg/cm2, 452 psi), or below approximately 118 kPa (1.2 kg/cm2, 17 psi).

Low Temperature Protection Control

Turn the A/C relay to OFF and stop the A/C compressor by the signal from the A/C auto amp., according to the evaporator passing air temperature detected by the intake sensor and the ambient temperature detected by the ambient sensor

Blower motor control system

Blower motor control system

System Diagram

System Description

Fan speed is automatically controlled by the temperature setting, ambient

temperature, in-vehicle temperature,

intake temperature, amount of sunload and air ...

Can communication system

Can communication system

System Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and e ...

Other materials:

M&A branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the combination meter for

damage, bend and loose connection

(unit side and connector side).

2.CHECK HARNESS FOR OPEN CI ...

STRG branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the steering angle sensor

for damage, bend and loose connection

(unit side and connector side).

2.CHECK HARNESS FOR OPE ...

Around View Monitor (if so equipped)

1. CAMERA button

WARNING

Failure to follow the warnings and instructions

for the proper use of the

Around View Monitor system could

result in serious injury or death.

The Around View Monitor is a convenience

feature and is not a substitute

for proper vehicle operation because it ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0055