Nissan Maxima Service and Repair Manual: Seatback thermal electric device

Description

Provides cooling and heat for the seatback.

Component Function Check

1.CHECK SEATBACK THERMAL ELECTRIC DEVICE FUNCTION

- Turn the climate controlled seat switch to the H (Heat) HI position and check that the seatback thermal electric device operates correctly.

- Turn the climate controlled seat switch to the C (Cool) HI position and check that the seatback thermal electric device operates correctly.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to SE-44, "Wiring Diagram".

1.CHECK SEATBACK THERMAL ELECTRIC DEVICE

Perform thermal electric device component inspection for the seatback. Refer to SE-19, "Component Inspection (Thermal Electric Device)".

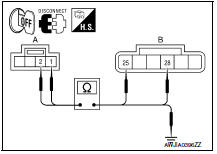

2.CHECK SEATBACK THERMAL ELECTRIC DEVICE CIRCUITS

- Turn ignition switch OFF.

- Disconnect seatback thermal electric device connector and climate controlled seat control unit connector B217.

- Check continuity between seatback thermal electric device connector B218 (A) terminals 1, 2 and climate controlled seat control unit connector B217 (B) terminals 25, 28.

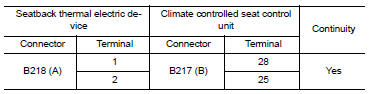

4. Check continuity between seatback thermal electric device connector B218 (A) terminals 1, 2 and ground.

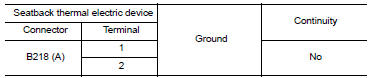

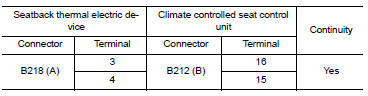

3.CHECK SEATBACK THERMAL ELECTRIC DEVICE SENSOR CIRCUITS

- Disconnect climate controlled seat control unit connector B212.

- Check continuity between seatback thermal electric device connector B218 (A) terminals 3, 4 and climate controlled seat control unit connector B212 (B) terminals 15, 16.

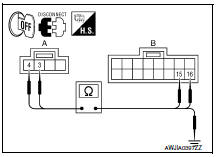

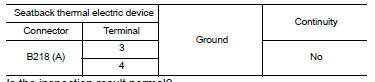

3. Check continuity between seatback thermal electric device connector B218 (A) terminals 3, 4 and ground.

Component Inspection (Thermal Electric Device)

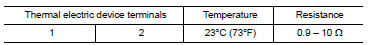

1.CHECK THERMAL ELECTRIC DEVICE

- Turn ignition switch OFF.

- Disconnect thermal electric device connector.

- Measure the resistance of the thermal electric device between terminals 1 and 2.

NOTE:

- The resistance value in the table below will change under any of the following conditions: air blowing across the thermal electric device

- changing the surrounding temperature of the thermal electric device

- measuring at other than 23C (73F)

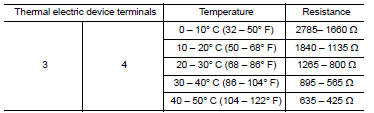

2.CHECK THERMAL ELECTRIC DEVICE SENSOR

Measure the resistance of the thermal electric device sensor between terminals 3 and 4.

Seat cushion thermal electric device

Seat cushion thermal electric device

Description

Provides cooling and heat for the seat cushion.

Component Function Check

1.CHECK SEAT CUSHION THERMAL ELECTRIC DEVICE FUNCTION

Turn the climate controlled seat switch to the H (Heat ...

Climate controlled seat switch

Climate controlled seat switch

Description

Provides inputs to the climate controlled seat control unit for climate

controlled seat operation.

Component Function Check

1.CHECK CLIMATE CONTROLLED SEAT SWITCH FUNCTION

Turn the c ...

Other materials:

Navigation System

Turn-by-turn route guidance can be displayed on

the vehicle information display.

To view turn-by-turn route guidance on the vehicle

information display, use or

and

scroll to on the vehicle

information display

menu.

City view

City view shows representation of intersections

with ...

P1610 lock mode

Description

Performs ID verification through BCM and Intelligent Key

when push-button ignition switch is pressed.

Prohibits the start of engine when an unregistered ID of Intelligent Key is

used.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCED ...

Periodic maintenance

WHEEL HUB

On-vehicle Service

Check axle and suspension parts for excessive play, wear or damage.

Shake each rear wheel to check for excessive play.

Inspection

Rear Wheel Bearing

Check axial end play.

Axial end play : Refer to RAX-8, "Wheel Bearing (Rear)".

Check ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0088