Nissan Maxima Service and Repair Manual: Can communication circuit

Diagnosis Procedure

1.CONNECTOR INSPECTION

- Turn the ignition switch OFF.

- Disconnect the battery cable from the negative terminal.

- Disconnect all the unit connectors on CAN communication system.

- Check terminals and connectors for damage, bend and loose connection.

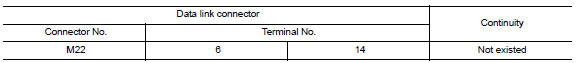

2.CHECK HARNESS CONTINUITY (SHORT CIRCUIT)

Check the continuity between the data link connector terminals.

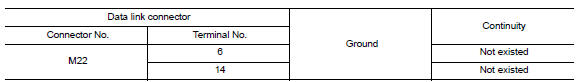

3.CHECK HARNESS CONTINUITY (SHORT CIRCUIT)

Check the continuity between the data link connector and the ground.

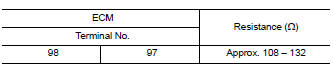

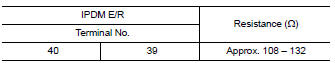

4.CHECK ECM AND IPDM E/R TERMINATION CIRCUIT

1. Remove the ECM and the IPDM E/R.

2. Check the resistance between the ECM terminals.

3. Check the resistance between the IPDM E/R terminals.

5.CHECK SYMPTOM

Connect all the connectors. Check if the symptoms described in the "Symptom (Results from interview with customer)" are reproduced.

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble diagnosis procedure when past error is detected.

6.CHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

- Turn the ignition switch OFF.

- Disconnect the battery cable from the negative terminal.

- Disconnect one of the unit connectors of CAN communication system.

NOTE: ECM and IPDM E/R have a termination circuit. Check other units first.

- Connect the battery cable to the negative terminal. Check if the

symptoms described in the "Symptom

(Results from interview with customer)" are reproduced.

NOTE: Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected.

IPDM-E branch line circuit

IPDM-E branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the IPDM E/R for damage,

...

Other materials:

Sunload sensor

Removal and Installation

REMOVAL

Remove the front LH speaker grille from the instrument panel.

Refer to IP-10, "Exploded View".

Disconnect the harness connector from the sunload sensor.

Release the sunload sensor tabs and remove the sunload sensor

(1) from the front LH speake ...

Air conditioning cut control

System Diagram

System Description

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM via the CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and

battery voltage.

SYSTEM DESCRIPTION

This system improves engine operation when ...

Vehicle recovery (freeing a stuck vehicle)

WARNING

To avoid vehicle damage, serious personal

injury or death when recovering a stuck

vehicle:

Contact a professional towing service

to recover the vehicle if you have any

questions regarding the recovery

procedure.

Tow chains or cables must be attached

only to main structural m ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.006