Nissan Maxima Service and Repair Manual: B260A ignition relay

Description

BCM turns ON the following relays to ignition power supply to each ECU when the ignition switch is turned ON.

- Ignition relay-1 (inside IPDM E/R)

- Ignition relay-2 (inside fuse block (J/B))

- Front blower motor relay

BCM checks any ignition relay ON request for consistency with the actual ignition relay operation status.

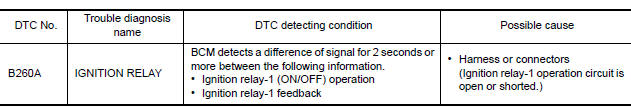

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC B260A is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to PCS-44, "DTC Logic".

- If DTC B260A is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to PCS-45, "DTC Logic".

- If DTC B260A is displayed with DTC B261A, first perform the trouble diagnosis for DTC B261A. Refer to PCS-60, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1. PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON under the following conditions, and wait for at least 2 seconds.

- CVT selector lever is in the P or N position.

- Release the brake pedal.

- Check "Self diagnostic result" with CONSULT.

Diagnosis Procedure

1.CHECK DATA MONITOR

- Turn ignition switch ON.

- Check IGN RLY1-REQ and IGN RLY status with CONSULT

2.CHECK CAN COMMUNICATION

Check CAN communication.

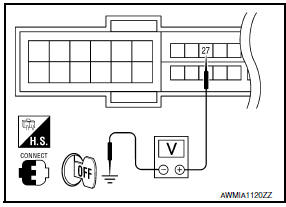

3.CHECK IGNITION RELAY-1 SIGNAL

- Turn ignition switch OFF.

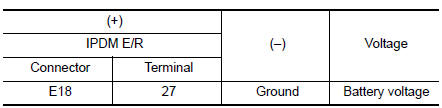

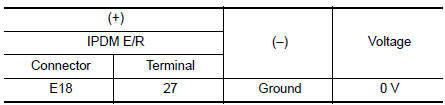

- Check voltage between IPDM E/R harness connector and ground.

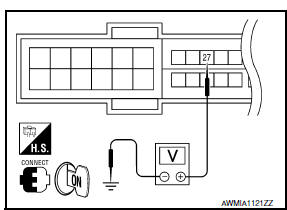

- Turn ignition switch ON.

- Check voltage between IPDM E/R harness connector and ground.

B2553 ignition relay

B2553 ignition relay

Description

BCM turns ON the following relays to ignition power supply to each ECU when

the ignition switch is turned

ON.

Ignition relay-1 (inside IPDM E/R)

Ignition relay-2 (inside fuse bl ...

B2614 ACC relay circuit

B2614 ACC relay circuit

Description

BCM controls the various electrical components and simultaneously supplies

power according to the power

supply position.

BCM checks the power supply position internally.

DTC Logic ...

Other materials:

Preparation

Special Service Tool

The actual shapes of the tools may differ from those illustrated her

Commercial Service Tool

...

RearView Monitor (if so equipped)

1. CAMERA button

WARNING

Failure to follow the warnings and instructions

for proper use of the Rear-

View Monitor system could result in serious

injury or death.

RearView Monitor is a convenience feature

and is not a substitute for proper

backing. Always turn and look out the

...

Front tweeter

Removal and Installation

REMOVAL

Remove the front pillar finisher. Refer to INT-24, "Removal and

Installation".

Remove the front tweeter speaker grille. Refer to IP-10, "Exploded

View".

Remove the front tweeter speaker screws (A).

Pull out front tweeter speaker (1), disconnect the ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0077