Nissan Maxima Service and Repair Manual: Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

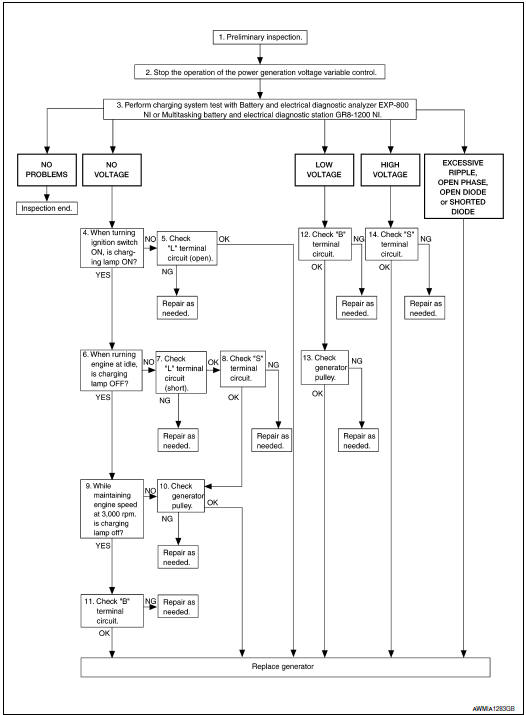

Work Flow (With EXP-800 NI or GR8-1200 NI)

CHARGING SYSTEM DIAGNOSIS WITH EXP-800 NI OR GR8-1200 NI

To test the charging system, use the following special service tools:

- EXP-800 NI Battery and electrical diagnostic analyzer

- GR8-1200 NI Multitasking battery and electrical diagnostic station

NOTE: Refer to the applicable Instruction Manual for proper charging system diagnosis procedures.

OVERALL SEQUENCE

DETAILED FLOW

NOTE: To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done as a set from start to finish.

1.PRELIMINARY INSPECTION

Perform the preliminary inspection

2.STOP POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

Stop the operation of the power generation voltage variable control in either of the following procedures.

- After selecting "ENGINE" using CONSULT, set the DUTY value of "ALTERNATOR DUTY" to 0 % by selecting "ALTERNATOR DUTY" of "Active Test". Continue "Active Test" until the end of inspection. (When the DUTY value is 0 or 100 %, the normal power generation is performed according to the characteristic of the IC regulator of the generator.)

- Turn the ignition switch OFF, and disconnect the battery current sensor connector. [However, DTC (P1550- P1554) of the engine might remain. After finishing the inspection, connect the battery current sensor connector and erase the self diagnosis results history of the engine using CONSULT.]

3.DIAGNOSIS WITH EXP-800 NI OR GR8-1200 NI

Perform the charging system test using Multitasking battery and electrical diagnostic station GR8-1200 NI or Battery and electrical diagnostic analyzer EXP-800 NI. Refer to the applicable Instruction Manual for proper testing procedures.

4.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

Turn the ignition switch ON.

5."L" TERMINAL CIRCUIT (OPEN) INSPECTION

Check "L" terminal circuit (open).

6.INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

7."L" TERMINAL CIRCUIT (SHORT) INSPECTION

Check "L" terminal circuit (short).

8."S" TERMINAL CIRCUIT INSPECTION

Check "S" terminal circuit

9.INSPECTION WITH CHARGE WARNING LAMP (ENGINE AT 3,000 RPM)

Increase and maintain the engine speed at 3,000 rpm.

10.INSPECTION OF GENERATOR PULLEY

Check generator pulley.

11."B" TERMINAL CIRCUIT INSPECTION

Check "B" terminal circuit

12."B" TERMINAL CIRCUIT INSPECTION

Check "B" terminal circuit

13.INSPECTION OF GENERATOR PULLEY

Check generator pulley

14."S" TERMINAL CIRCUIT INSPECTION

Check "S" terminal circuit.

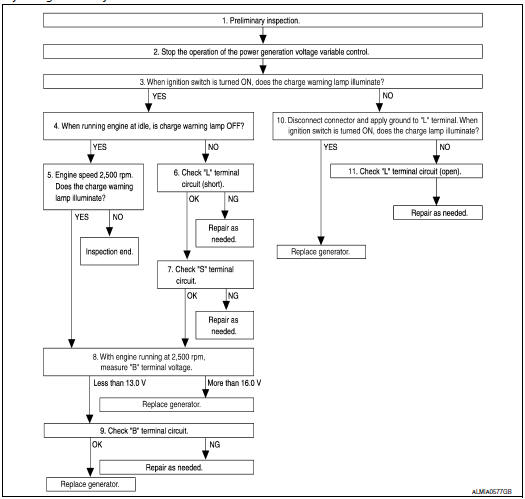

Work Flow (Without EXP-800 NI or GR8-1200 NI)

OVERALL SEQUENCE

Before performing a generator test, make sure that the battery is fully charged. A 30-volt voltmeter and suitable test probes are necessary for the test.

- Before starting, inspect the fusible link.

- Use fully charged battery

DETAILED FLOW

1.PRELIMINARY INSPECTION

Perform the preliminary inspection

2.STOP POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

Stop the operation of the power generation voltage variable control in either of the following procedures:

- After selecting "ENGINE" using CONSULT, set the DUTY value of "ALTERNATOR DUTY" to 0 % by selecting "ALTERNATOR DUTY" with "Active Test". Continue "Active Test" until the end of inspection. (When the DUTY value is 0 or 100 %, the normal power generation is performed according to the characteristic of the IC regulator of the generator.)

- Turn the ignition switch OFF, and disconnect the battery current sensor connector. [However, DTC (P1550 - P1554) of the engine might remain. After finishing the inspection, connect the battery current sensor connector and erase the self-diagnostic results history of the engine using CONSULT.]

3.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS TURNED ON)

When ignition switch is turned ON.

4.INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle

5.INSPECTION WITH CHARGE WARNING LAMP (ENGINE AT 2,500 RPM)

Increase and maintain the engine speed at 2,500 rpm.

6."L" TERMINAL CIRCUIT (SHORT) INSPECTION

Check terminal "L" circuit for (short).

7. "S" TERMINAL CIRCUIT INSPECTION

Check terminal "S" circuit.

8.MEASURE "B" TERMINAL VOLTAGE

Start engine. With engine running at 2,500 rpm, measure "B" terminal voltage.

9."B" TERMINAL CIRCUIT INSPECTION

Check "B" terminal circuit

10.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

- Disconnect generator connector and apply ground to "L" terminal.

- Turn the ignition switch ON.

11.CHECK "L" TERMINAL CIRCUIT (OPEN)

Check "L" terminal circuit (OPEN).

Charging system

Charging system

...

Other materials:

Air Cleaner And Air Duct

Removal and Installation

Air duct hose and resonator assembly

Front air duct

Air cleaner case (lower)

Grommets

Air cleaner case mounting bracket

Bracket

Air cleaner filter

Air cleaner case (upper)

Mass air flow sensor

To electric throttle control

actuator

...

Headlamp

Wiring Diagram

...

Front door speaker

Removal and Installation

REMOVAL

Remove the front door finisher. Refer to INT-18, "Removal and

Installation".

Remove the front door speaker screws (A).

Disconnect the harness connector from the front door speaker

(1) and remove.

Remove the front door speaker spacer screws ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0057