Nissan Maxima Service and Repair Manual: Removal and installation

GENERATOR

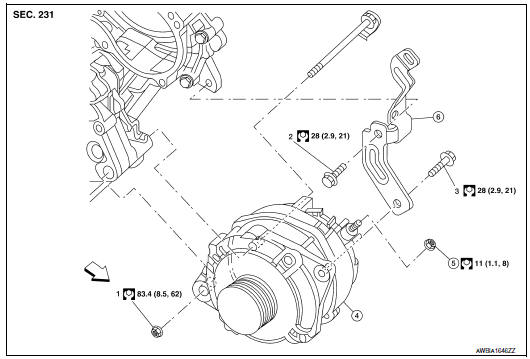

Exploded View

- -3 Tightening order

- Generator

- B terminal nut

- Generator bracket

Front

Front

Removal and Installation

REMOVAL

- Remove hoodledge covers (LH/RH).

- Remove cooling fan assembly. Refer to CO-16, "Removal and Installation".

- Remove the A/C compressor. Refer to HA-37, "Removal and Installation for Compressor".

- Remove A/C idler pulley EM-15, "Removal and Installation of Drive Belt Auto-tensioner".

- Disconnect the oil pressure switch EM-36, "Exploded View".

- Disconnect the generator harness connectors.

- Remove the generator bolt and nuts, using power tools.

- Remove generator bracket.

- Slide the generator out and remove.

INSTALLATION

Installation is in the reverse order of removal. Refer to CHG-28, "Exploded View"

- Temporarily tighten bolts and nut, then finish tightening in the

specified numerical order.

CAUTION: Be sure to tighten "B" terminal nut carefully. - Install generator and check tension of belt. Refer to EM-14, "Checking Drive Belts".

- For this model, the power generation voltage variable control system that controls the power generation voltage of the generator has been adopted. Therefore, the power generation voltage variable control system operation inspection should be performed after replacing the generator, and then make sure that the system operates normally. Refer to CHG-11, "Diagnosis Procedure".

Inspection

GENERATOR PULLEY INSPECTION

Perform the following.

- Make sure that generator pulley does not rattle.

- Make sure that generator pulley nut is tight.

NOTE: Replace the generator as an assembly if necessary.

Preparation

Preparation

PREPARATION

Special Service Tool

The actual shapes of the tools may differ from those illustrated here.

Commercial Service Tool

...

Service data and specifications (SDS)

Service data and specifications (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Generator

*: Always check with the Parts Department for the latest parts information ...

Other materials:

Microphone

Removal and Installation

REMOVAL

Remove the front room/map lamp assembly. Refer to INL-84, "Removal

and Installation".

Detach the microphone connector (A).

Remove the front room/map lamp covers (1), then remove the map lamp

assembly cover (2).

R ...

USB connector

Removal and Installation

REMOVAL

Remove the center console assembly. Refer to IP-14, "Removal and

Installation".

Push the pawl from the back of the center console to remove the

USB interface (1).

INSTALLATION

Installation is in the reverse order of removal ...

Front wiper motor ground circuit

Diagnosis Procedure

1.CHECK FRONT WIPER MOTOR (GND) OPEN CIRCUIT

Turn the ignition switch OFF.

Disconnect front wiper motor.

Check continuity between front wiper motor harness connector

and ground.

...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0061