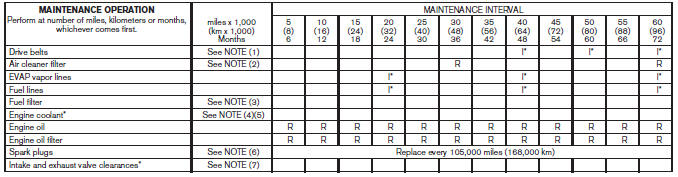

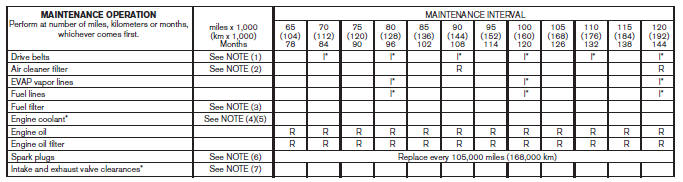

Nissan Maxima Owners Manual: Emission control system maintenance

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, D = Drain water

NOTE:

(1) After 40,000 miles (64,000 km) or 48 months, inspect every 10,000 miles (16,000 km) or 12 months. Replace the drive belts if found damaged.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Periodic maintenance is not required.

(4) First replacement interval is 105,000 miles (168,000 km) or 84 months. After first replacement, replace every 75,000 miles (120,000 km) or 60 months.

(5) Use only Genuine NISSAN Long Life Antifreeze/Coolant (blue) or equivalent with proper mixture ration of 50% antifreeze and 50% demineralized or distilled water. Mixing any other type of coolant or the use of non-distilled water may reduce the life expectancy of the factory fill coolant.

(6) Replace spark plug when the plug gap exceeds 0.053 in (1.35 mm) even if within specified periodic replacement mileage.

(7) Periodic maintenance is not required. However, if valve noise increased, inspect valve clearance.

* Maintenance items and intervals with "*" are recommended by NISSAN for reliable vehicle operation. The owner need not perform such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

Standard maintenance

Standard maintenance

The following tables show the standard maintenance

schedule. Depending upon weather and

atmospheric conditions, varying road surfaces,

individual driving habits and vehicle usage, additional

or mo ...

Chassis & body maintenance

Chassis & body maintenance

Abbreviations: I = Inspect and correct or replace as necessary, R =

Replace,

NOTE:

Maintenance items with " " should be performed more frequently according

to "Maintenance under severe d ...

Other materials:

Parking brake switch signal circuit

Description

Transmits the parking brake switch signal to the

combination meter.

Component Function Check

1.COMBINATION METER INPUT SIGNAL

Select "METER/M&A" on CONSULT.

Monitor "PKB SW" of "DATA MONITOR" while

applying and releasing the parking brake.

> ...

Refrigerant

Description

CONNECTION OF SERVICE TOOLS AND EQUIPMENT

Shut-off valve

A/C service valve

Recovery/recycling/recharging equipment

Refrigerant container (HFC-134a)

Weight scale (J-39650)

Vacuum pump (J-39649)

Manifold gauge set (J-39183)

Preferred (best) method

A ...

Service data and specifications (SDS)

Idle Speed

Ignition Timing

Calculated Load Value

Mass Air Flow Sensor

*: Engine is warmed up to normal operating temperature and running under no

load. ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0059