Nissan Maxima Service and Repair Manual: Rocker Cover

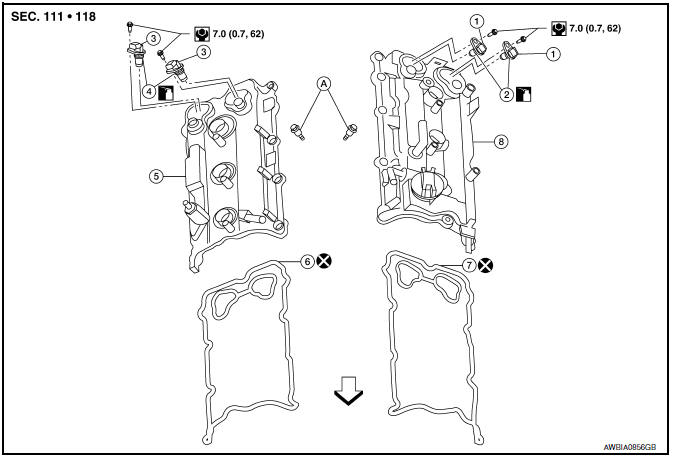

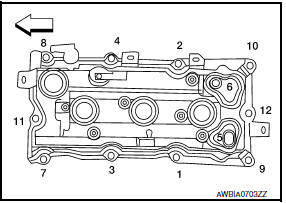

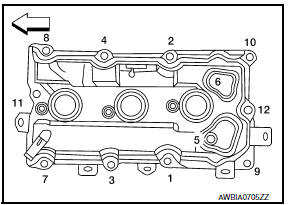

Exploded View

- Camshaft position sensors (LH)

- O-rings

- Camshaft position sensors (RH)

- O-rings

- Rocker cover (RH)

- Rocker cover gasket (RH)

- Rocker cover gasket (LH)

- Rocker cover (LH)

- Refer to INSTALLATION

Front

Front

Removal and Installation (LH)

REMOVAL

- Remove the engine room cover. Refer to EM-23, "Removal and Installation".

- Remove front air duct. Refer to EM-24, "Removal and Installation".

- Remove blow by hose from rocker cover.

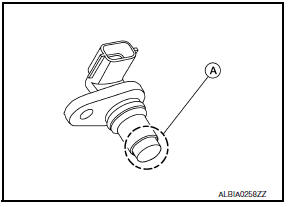

- Remove camshaft position sensors.

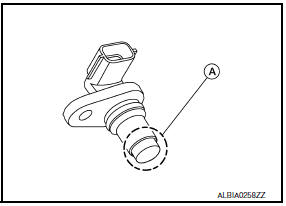

CAUTION:

- Handle carefully to avoid dropping and shocks.

- Do not disassemble.

- Do not allow metal powder to adhere to magnetic part at sensor tip (A).

- Do not place sensors in a location where they are exposed to magnetism.

- Remove the ignition coils. Refer to EM-42, "Removal and Installation (LH)".

CAUTION: Do not shock ignition coils.

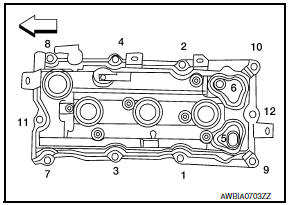

- Remove (LH) rocker cover bolts from cylinder head in the reverse order as shown.

: Engine front

: Engine front

- Remove the rocker cover and gasket.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION: Do not reuse rocker cover gasket.

- Apply sealant to the areas on the front corners using Tool.

- Use Genuine Silicone RTV Sealant or equivalent. Refer to GI-21, "Recommended Chemical Products and Sealants".

Tool number : WS39930000 ( - )

CAUTION:

- Installation should be done within 5 minutes after applying liquid gasket.

- Do not fill the engine with oil for at least 30 minutes after the components are installed to allow the sealant to cure.

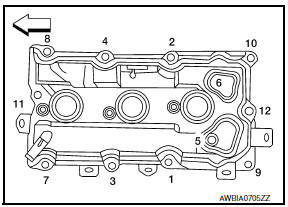

- Tighten the rocker cover bolts in two steps in the order shown.

: Engine front

: Engine front

Rocker cover bolts

Step 1 : 1.96 N*m (0.20 kg-m, 17 in-lb)

Step 2 : 8.33 N*m (0.85 kg-m, 74

in-lb)

Removal and Installation (RH)

REMOVAL

- Remove the engine room cover. Refer to EM-23, "Removal and Installation".

- Remove the front air duct and air duct hose and resonator assembly. Refer to EM-24, "Removal and Installation".

- Remove the intake manifold collector. Refer to EM-28, "Removal and

Installation".

4. Remove ignition coils. Refer to EM-42, "Removal and Installation (RH)". CAUTION: Do not shock ignition coils.

- Remove camshaft position sensors.

CAUTION:

- Handle carefully to avoid dropping and shocks.

- Do not disassemble.

- Do not allow metal powder to adhere to magnetic part at sensor tip (A).

- Do not place sensors in a location where they are exposed to magnetism.

- Remove RH rocker cover bolts from cylinder head in the reverse order as shown.

: Engine front

: Engine front

- Remove the rocker cover and gasket.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION: Do not reuse gaskets.

- Apply sealant to the areas on the front corners using Tool.

- Use Genuine Silicone RTV Sealant or equivalent. Refer to GI-21, "Recommended Chemical Products and Sealants".

Tool number : WS39930000 ( - )

CAUTION:

- Installation should be done within 5 minutes after applying liquid gasket.

- Do not fill the engine with oil for at least 30 minutes after the components are installed to allow the sealant to cur

- Tighten the rocker cover bolts in two steps in the order shown.

: Engine front

: Engine front

Rocker cover bolts

Step 1 : 1.96 N*m (0.20 kg-m, 17 in-lb)

Step 2 : 8.33 N*m (0.85 kg-m, 74

in-lb)

Fuel Injector And Fuel Tube

Fuel Injector And Fuel Tube

Exploded View

Fuel feed hose

Quick connector cap

Fuel tube

O-ring

Fuel damper

Fuel damper cap

Clip

O-ring (black)

Fuel injector

O-ring (green)

Refer to INSTALLATI ...

Intake Valve Timing Control

Intake Valve Timing Control

Exploded View

Intake valve timing control solenoid valve cover gasket (LH)

Intake valve timing control solenoid valve cover gasket (RH)

Intake valve timing control solenoid valve cover (RH) ...

Other materials:

Wheel sensors

Exploded View - Front Wheel Sensor

Front wheel sensor

Color line (slant line)

Front wheel sensor harness connector

Front

Removal and Installation - Front Wheel Sensor

CAUTION:

Be careful not to damage wheel sensor edge and sensor rotor

teeth.

When pul ...

Audible reminders

Brake pad wear warning

The disc brake pads have audible wear warnings.

When a disc brake pad requires replacement, it

makes a high pitched scraping sound when the

vehicle is in motion, whether or not the brake

pedal is depressed. Have the brakes checked as

soon as possible if the warning sou ...

Seatback pockets

The seatback pockets are located on the back of

the driver's and passenger's seats. The pockets

can be used to store maps.

WARNING

To ensure proper operation of the passenger's

NISSAN Advanced Air Bag System,

please observe the following items:

Do not allow a passenger in the rear

se ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0087