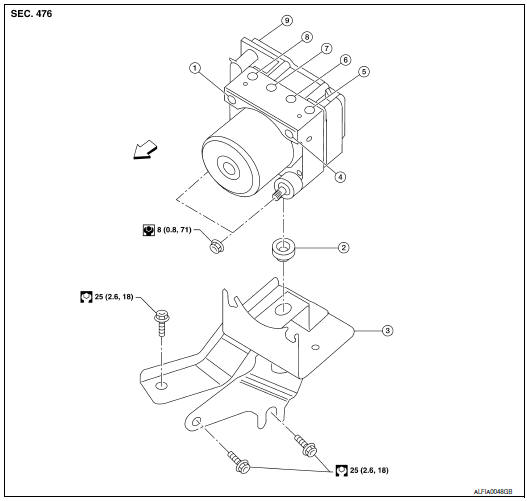

Nissan Maxima Service and Repair Manual: ABS actuator and electric unit (control unit)

Exploded View

- From master cylinder secondary side

- Grommet

- ABS actuator and electric unit (control unit) bracket

- From master cylinder primary side

- To front LH brake caliper

- To rear RH brake caliper

- To rear LH brake caliper

- To front RH brake caliper

- ABS actuator and electric unit (control

unit)

Front

Front

Removal and Installation

CAUTION:

- Before removal, disconnect the battery negative terminal.

- To disconnect the brake tubes, use a flare nut wrench to prevent the flare nuts and brake tubes from being damaged. To connect the brake tubes, use a flare nut torque wrench to tighten to the specified torque.

- Do not drop the ABS actuator and electric unit (control unit).

- Do not remove and install the ABS actuator and electric unit (control unit) by holding it by the harness.

- After installation, bleed the air from the brake lines. Refer to BR-16, "Bleeding Brake System".

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

- Disconnect the battery negative terminal. Refer to PG-67, "Removal and Installation (Battery)".

- Remove the front wiper arms. Refer to WW-78, "FRONT WIPER ARMS : Removal and Installation".

- Remove the cowl top and RH cowl top extension. Refer to EXT-21, "Removal and Installation".

- Disconnect the wiper washer hose.

- Remove the strut tower bar. Refer to FSU-13, "Exploded View".

- Disconnect the ABS actuator and electric unit (control unit) connector.

- Loosen the brake tube flare nuts, then disconnect the brake tubes from the ABS actuator and electric unit (control unit).

- Remove the ABS actuator and electric unit (control unit) nuts.

- Remove the ABS actuator and electric unit (control unit).

- Remove the ABS actuator and electric unit (control unit) bracket as necessary.

INSTALLATION

Installation is in the reverse order of removal.

- Bleed brake system, check and adjust brake fluid level as necessary.

CAUTION: Perform the neutral position adjustment for the steering angle sensor

Sensor rotor

Sensor rotor

Removal and Installation - Front Sensor Rotor

The front wheel sensor rotor is an integral part of the wheel hub and bearing

assembly and cannot be disassembled.

Removal and Installation - Rear Sen ...

Yaw rate/side/decel G sensor

Yaw rate/side/decel G sensor

Exploded View

Yaw rate/side/decel G sensor

Yaw rate/side/decel G sensor harness

connector

Front

Removal and Installation

CAUTION:

Do not drop or strike the yaw rate/sid ...

Other materials:

Vehicle security system

Wiring Diagram

...

Preparation

Special Service Tool

The actual shapes of the tools may differ from those illustrated her

Commercial Service Tool

...

Washer level switch

Removal and Installation

REMOVAL

Position the RH front fender protector back. Refer to EXT-24,

"Removal and Installation".

Remove the engine under cover.

Remove the RH front fender protector side cover. Refer to EXT-24,

"Removal and Installation".

Disconnect the front washer level ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0064