Nissan Maxima Service and Repair Manual: P0138, P0158 HO2S2

Description

The heated oxygen sensor 2, after three way catalyst (manifold), monitors the oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1 are shifted, the air-fuel ratio is controlled to stoichiometric, by the signal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates voltage from approximately 1 V in richer conditions to 0 V in leaner conditions.

Under normal conditions the heated oxygen sensor 2 is not used for engine control operation.

DTC Logic

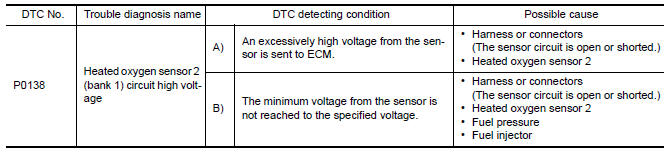

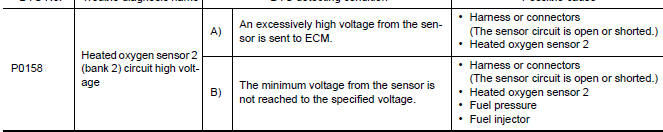

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/ F) sensor 1. The oxygen storage capacity of the three way catalyst (manifold) causes the longer switching time.

MALFUNCTION A

To judge the malfunctions of heated oxygen sensor 2, ECM monitors whether the voltage is unusually high during various driving conditions such as fuel cut.

MALFUNCTION B

To judge the malfunctions of heated oxygen sensor 2, ECM monitors whether the minimum voltage of sensor is sufficiently low during various driving conditions such as fuel cut.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

2.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION A

- Start engine and warm it up to the normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Check 1st trip DTC.

3.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION B

NOTE: For better results, perform "DTC WORK SUPPORT" at a temperature of 0 to 30 C (32 to 86 F).

- Select "DATA MONITOR" mode with CONSULT.

- Start engine and warm it up to the normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 1 minute.

- Check that "COOLAN TEMP/S" indicates more than 70C (158F).

If not, warm up engine and go to next step when "COOLAN TEMP/S" indication reaches 70C (158F).

- Open engine hood.

- Select "HO2S2 (B1) P1146" (for DTC P0138) or "HO2S2 (B2) P1166" (for DTC P0158) of "HO2S2" in "DTC WORK SUPPORT" mode with CONSULT.

- Follow the instruction of CONSULT display. NOTE: It will take at most 10 minutes until "COMPLETED" is displayed.

- Touch "SELF-DIAG RESULTS".

4.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION B AGAIN

- Turn ignition switch OFF and leave the vehicle in a cool place (soak the vehicle).

- Perform DTC confirmation procedure again.

5.PERFORM COMPONENT FUNCTION CHECK FOR MALFUNCTION B

Perform component function check.

NOTE: Use component function check to check the overall function of the heated oxygen sensor 2 circuit. During this check, a 1st trip DTC might not be confirmed.

Component Function Check

1.PERFORM COMPONENT FUNCTION CHECK-I

Without CONSULT

- Start engine and warm it up to the normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 1 minute.

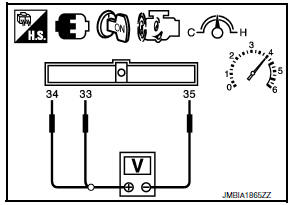

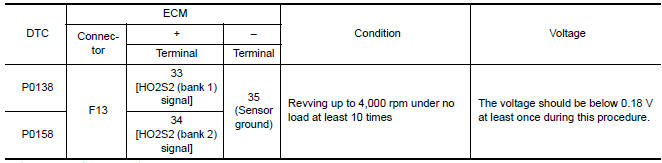

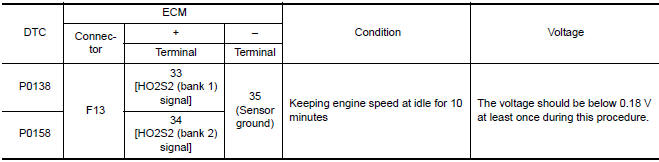

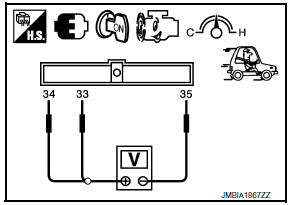

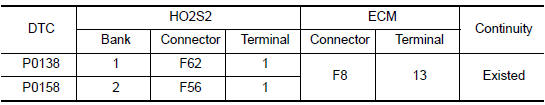

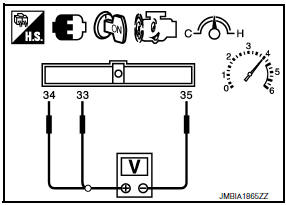

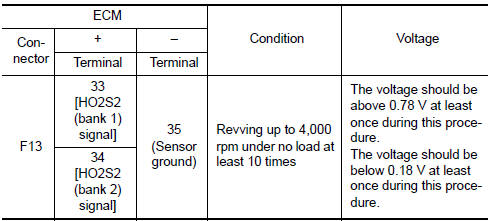

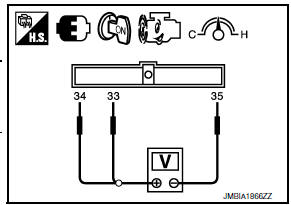

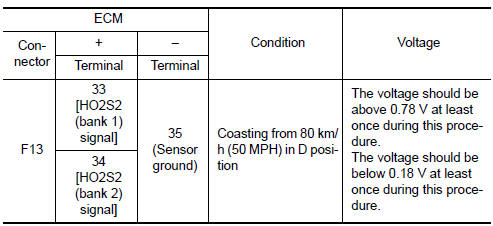

- Check the voltage between ECM harness connector terminals under the following conditions

2.PERFORM COMPONENT FUNCTION CHECK-II

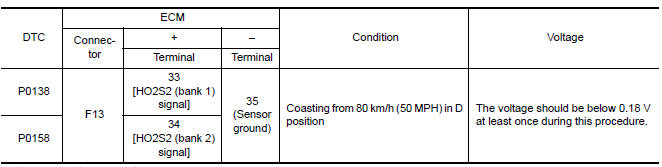

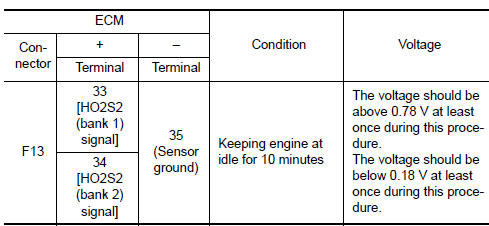

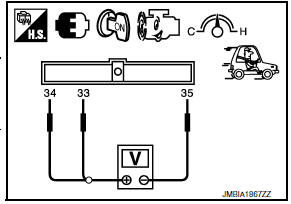

Check the voltage between ECM harness connector terminals under the following conditions.

3.PERFORM COMPONENT FUNCTION CHECK-III

Check the voltage between ECM harness connector terminals under the following conditions.

Diagnosis Procedure

1.INSPECTION START

Confirm the detected malfunction (A or B).

2.CHECK GROUND CONNECTION

- Turn ignition switch OFF.

- Check ground connection E9.

3.CHECK HO2S2 CONNECTOR FOR WATER

- Disconnect heated oxygen sensor 2 (HO2S2) harness connector.

- Check that water is not inside conductors.

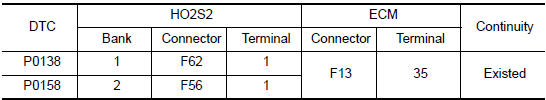

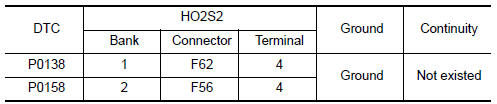

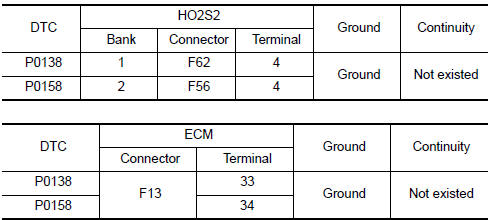

4.CHECK HO2S2 GROUND CIRCUIT FOR OPEN AND SHORT

- Disconnect ECM harness connector.

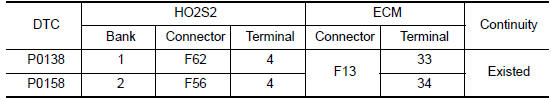

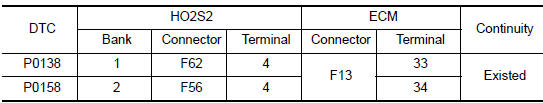

- Check the continuity between HO2S2 harness connector and ECM harness connector.

- Also check harness for short to ground and short to power.

5.CHECK HO2S2 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

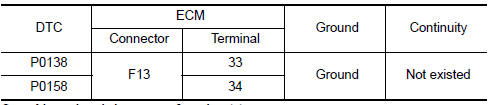

- Check the continuity between HO2S2 harness connector and ECM harness connector.\

- Check the continuity between HO2S2 harness connector and ground, or ECM harness connector and ground.

- Also check harness for short to power.

6.CHECK HEATED OXYGEN SENSOR 2

7.REPLACE HEATED OXYGEN SENSOR 2

Replace malfunctioning heated oxygen sensor 2.

CAUTION:

- Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a hard surface such as a concrete floor; use a new one.

- Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner [commercial service tool (J-43897-18 or J-43897-12)] and approved anti-seize lubricant (commercial service tool).

9.CHECK GROUND CONNECTION

- Turn ignition switch OFF.

- Check ground connection E9.

10.CLEAR MIXTURE RATIO SELF-LEARNING VALUE

- Clear the mixture ratio self-learning value. Refer to EC-24, "MIXTURE RATIO SELF-LEARNING VALUE CLEAR : Special Repair Requirement".

- Run engine for at least 10 minutes at idle speed.

11.CHECK HO2S2 GROUND CIRCUIT FOR OPEN AND SHORT

- Turn ignition switch OFF.

- Disconnect heated oxygen sensor 2 harness connector.

- Disconnect ECM harness connector.

- Check the continuity between HO2S2 harness connector and ECM harness connector.

- Also check harness for short to ground and short to power.

12.CHECK HO2S2 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

- Check the continuity between HO2S2 harness connector and ECM harness connector.

- Check the continuity between HO2S2 harness connector and ground, or ECM harness connector and ground.

- Also check harness for short to power.

13.CHECK HEATED OXYGEN SENSOR 2

14.REPLACE HEATED OXYGEN SENSOR 2

Replace malfunctioning heated oxygen sensor 2.

CAUTION:

- Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a hard surface such as a concrete floor; use a new one.

- Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner [commercial service tool (J-43897-18 or J-43897-12)] and approved anti-seize lubricant (commercial service tool).

15.CHECK INTERMITTENT INCIDENT

Component Inspection

1.INSPECTION START

2.CHECK HEATED OXYGEN SENSOR 2

With CONSULT

- Turn ignition switch ON and select "DATA MONITOR" mode with CONSULT.

- Start engine and warm it up to the normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 1 minute.

- Select "FUEL INJECTION" in "ACTIVE TEST" mode, and select "HO2S2 (B1)/(B2)" as the monitor item with CONSULT.

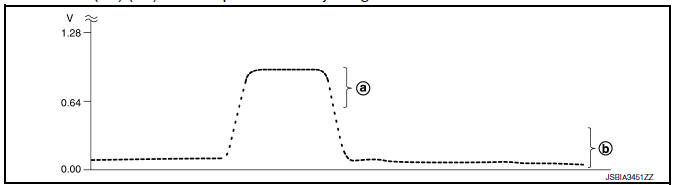

- Check "HO2S2 (B1)/(B2)" at idle speed when adjusting "FUEL INJECTION" to +-25%.

- "HO2S2 (B1)/(B2)" should be above 0.78 V at least once when the "FUEL INJECTION" is +25%.

- "HO2S2 (B1)/(B2)" should be below 0.18 V at least once when the "FUEL INJECTION" is −25%.

3.CHECK HEATED OXYGEN SENSOR 2-I

Without CONSULT

- Start engine and warm it up to the normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 1 minute.

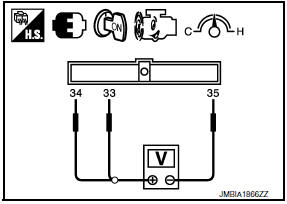

- Check the voltage between ECM harness connector terminals under the following conditions.

4.CHECK HEATED OXYGEN SENSOR 2-II

Check the voltage between ECM harness connector terminals under the following conditions.

5.CHECK HEATED OXYGEN SENSOR 2-III

Check the voltage between ECM harness connector terminals under the following conditions.

6.REPLACE HEATED OXYGEN SENSOR 2

Replace malfunctioning heated oxygen sensor 2.

CAUTION:

- Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a hard surface such as a concrete floor; use a new one.

- Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner [commercial service tool (J-43897-18 or J-43897-12)] and approved anti-seize lubricant (commercial service tool).

P0137, P0157 HO2S2

P0137, P0157 HO2S2

Description

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the air fuel rati ...

P0139, P0159 HO2S2

P0139, P0159 HO2S2

Description

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the air fuel rati ...

Other materials:

Front fog lamp aiming adjustment

Description

PREPARATION BEFORE ADJUSTING

CAUTION: Do not use organic solvent

(thinner, gasoline etc.).

NOTE: For

details, refer to the regulations in your own country.

Before performing

aiming adjustment, check the following.

Keep all tires inflated to correct pressure.

Place vehicle ...

System temporarily unavailable

The following are conditions in which the ICC

system may be temporarily unavailable. In these

instances, the ICC system may not cancel and

may not be able to maintain the selected following

distance from the vehicle ahead.

Condition A

Under the following conditions, the ICC system is

auto ...

Answer back horn feature

If desired, the answer back horn feature can be

deactivated using the Intelligent Key. When it is

deactivated and the LOCK

button is

pushed, the hazard indicator lights flash twice.

When the UNLOCK button is pushed,

neither

the hazard indicator lights nor the horn operates.

NO ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0063