Nissan Maxima Service and Repair Manual: Cooling fan

Description

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, refrigerant pressure, and air conditioner ON signal. The control system has 4-step control [HIGH/MIDDLE/LOW/OFF].

COOLING FAN MOTOR

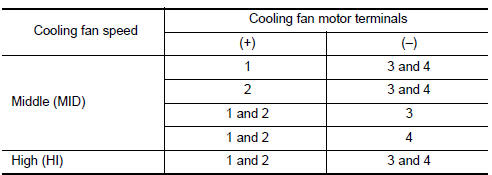

The cooling fan operates at each speed when the current flows in the cooling fan motor as per the following.

The cooling fan operates at low (LOW) speed when cooling fan motors-1 and -2 are circuited in series under the middle speed condition.

Component Function Ch

1.CHECK COOLING FAN FUNCTION

With CONSULT

- Turn ignition switch ON.

- Perform "COOLING FAN" in "ACTIVE TEST" mode with CONSULT.

- Check that cooling fan speed varies according to the percentage.

Without CONSULT

- Perform IPDM E/R auto active test and check cooling fan motors operation, refer to PCS-11, "Diagnosis Description".

- Check that cooling fan operates.

Diagnosis Procedure

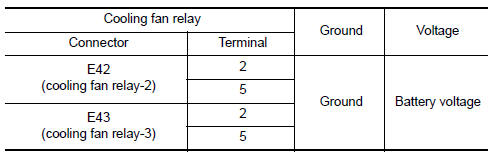

1.CHECK COOLING FAN RELAY POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect cooling fan relays-2, -3.

- Turn ignition switch ON.

- Check the voltage between cooling fan relays-2, -3 harness connectors and ground.

2.DETECT MALFUNCTIONING PART

Check the following.

- 10 A fuse (No. 33)

- 40 A fusible link (letter K)

- Joint connector-E01 E1

- IPDM E/R harness connector E18

- Junction block connectors E44, E48

- Harness for open or short between cooling fan relay-2 and battery

- Harness for open or short between cooling fan relay-3 and battery

- Harness for open or short between cooling fan relay-2 and IPDM E/R

- Harness for open or short between cooling fan relay-3 and IPDM E/R

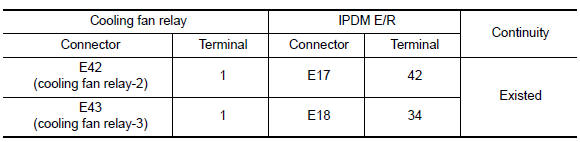

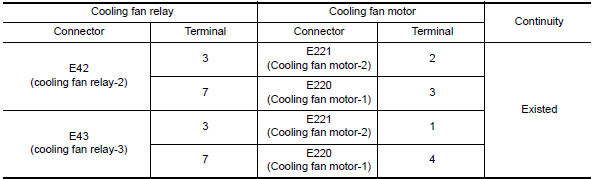

3.CHECK COOLING FAN RELAY OUTPUT SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect IPDM E/R harness connectors.

- Check the continuity between cooling fan relay-2, -3 harness connectors and IPDM E/R harness connector.

- Also check harness for short to ground and short to power.

4.DETECT MALFUNCTIONING PART

Check the following.

- Harness for open or short between cooling fan relay-2 and IPDM E/R

- Harness for open or short between cooling fan relay-3 and IPDM E/R

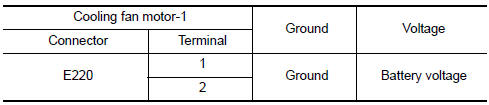

5.CHECK COOLING FAN MOTOR POWER SUPPLY CIRCUIT

- Disconnect cooling fan motor-1 harness connector.

- Check the voltage between cooling fan motor-1 harness connector and ground.

6.DETECT MALFUNCTIONING PART

Check the following.

- 40 A fusible link (letter M)

- Harness connector E12, E203

- Harness for open or short between cooling fan motor-1 and battery

7.CHECK COOLING FAN MOTOR CIRCUIT-I

- Disconnect cooling fan motor-2 harness connector.

- Check the continuity between cooling fan relay-2, -3 harness connectors and cooling fan motor-1, -2 harness connectors.

- Also check harness for short to ground and short to power.

8.DETECT MALFUNCTIONING PART

Check the following.

- Joint connector-E02 E20

- Harness connector E12, E203

- Harness for open or short between cooling fan motor-1 and cooling fan relay-2

- Harness for open or short between cooling fan motor-1 and cooling fan relay-3

- Harness for open or short between cooling fan motor-2 and cooling fan relay-2

- Harness for open or short between cooling fan motor-2 and cooling fan relay-3

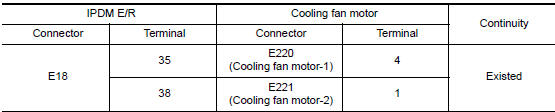

9.CHECK COOLING FAN MOTOR CIRCUIT-II

- Check the continuity between IPDM E/R harness connector and cooling fan motor-1, -2 harness connector.

- Also check harness for short to ground and short to power.

10.DETECT MALFUNCTIONING PART

Check the following.

- Joint connector-E02 E20

- Harness connector E70, E305

- Harness for open or short between cooling fan motor-1 and IPDM E/R

- Harness for open or short between cooling fan motor-2 and IPDM E/R

11.CHECK COOLING FAN MOTOR CIRCUIT-III

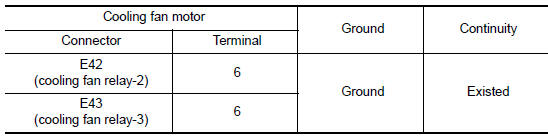

- Check the continuity between cooling fan relay-2, -3 harness connectors and ground.

- Also check harness for short to ground and short to power.

12.CHECK COOLING FAN MOTOR CIRCUIT-IV

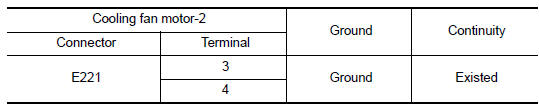

- Check the continuity between cooling fan motor-2 harness connector and ground.

- Also check harness for short to ground and short to power.

13.CHECK COOLING FAN RELAYS-2 AND -3

14.CHECK COOLING FAN MOTORS-1 AND -2

15.CHECK INTERMITTENT INCIDENT

Component Inspection (Cooling Fan Motor)

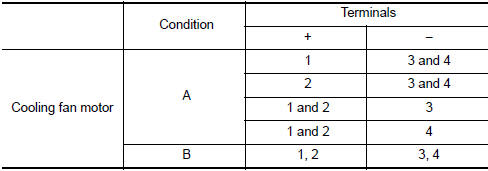

1.CHECK COOLING FAN MOTOR

- Turn ignition switch OFF.

- Disconnect cooling fan motor harness connector.

- Supply cooling fan motor terminals with battery voltage and check operation.

Check that cooling fan speed of condition B is higher than that of A.

Component Inspection (Cooling Fan Relay)

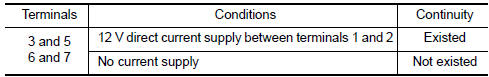

1.CHECK COOLING FAN RELAY

- Disconnect cooling fan relays -2, -3 harness connectors.

- Check continuity between cooling fan relay -2, -3 terminals under the following conditions.

ASCD indicator

ASCD indicator

Description

ASCD indicator lamp illuminates to indicate ASCD operation status. CRUISE is

integrated in combination

meter.

CRUISE illuminates when MAIN switch on ASCD steering switch is turned ...

Check cooling fan relay

Check cooling fan relay

Description

The electrical load signal (Headlamp switch signal, rear window defogger

switch signal, etc.) is transferred via

the CAN communication line from BCM to ECM via the IPDM E/R.

Componen ...

Other materials:

Power steering fluid

Check the fluid level in the reservoir.

The fluid level should be checked when the fluid

is cold at fluid temperatures of 32 to 86ºF (0 to

30ºC). The fluid level can be checked with the

level gauge which is attached to the cap. To

check the fluid level, remove the cap. The fluid ...

Power supply and ground circuit

A/C AUTO AMP.

A/C AUTO AMP.: Description

COMPONENT DESCRIPTION

A/C Auto Amp. (Air Conditioner Automatic Amplifier)

The A/C auto amp. (1) has a built-in microcomputer that processes

information sent from various sensors needed for air conditioner

operation. The air mix door motor(s), the mode d ...

Both side headlamps (LO) are not turned on

Description

The headlamps (both sides) do not turn ON in any lighting switch setting.

Diagnosis Procedure

1.CHECK COMBINATION SWITCH (LIGHTING AND TURN SIGNAL SWITCH)

Check the combination switch (lighting and turn signal switch).

2.CHECK HEADLAMP (LO) REQUEST SIGNAL INPUT

CONSULT DATA MONITOR ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0054