Nissan Maxima Service and Repair Manual: Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

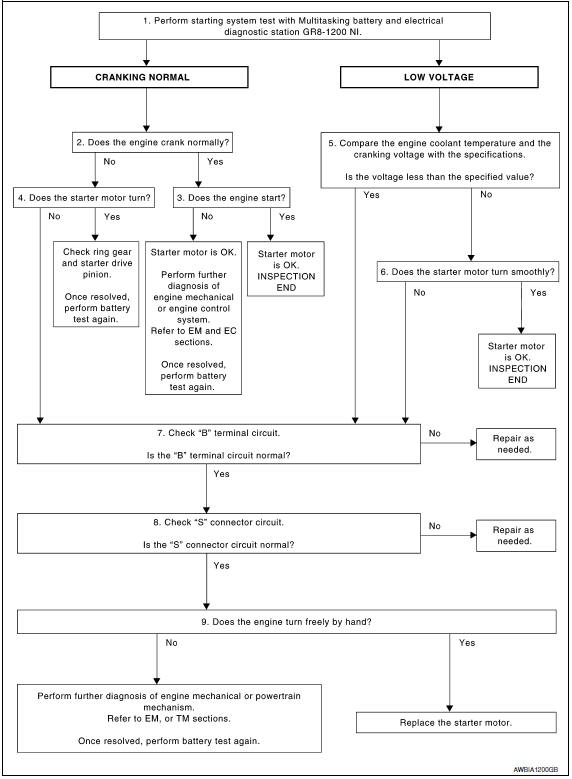

Work Flow (With GR8-1200 NI)

STARTING SYSTEM DIAGNOSIS WITH GR8-1200 NI

To test the starting system, use the following special service tool:

- GR8-1200 NI Multitasking battery and electrical diagnostic station

NOTE: Refer to the diagnostic station Instruction Manual for proper starting system diagnosis procedures

OVERALL SEQUENCE

DETAILED FLOW

NOTE: To ensure a complete and thorough diagnosis, the battery, starter motor and generator test segments must be done as a set from start to finish.

1.DIAGNOSIS WITH MULTITASKING BATTERY AND ELECTRICAL DIAGNOSTIC STATION GR8-1200 NI

Perform the starting system test with Multitasking battery and electrical diagnostic station GR8-1200 NI. For details and operating instructions, refer to diagnostic station Instruction Manual.

2.CRANKING CHECK

Check that the starter motor operates properly.

3.ENGINE START CHECK

Check that the engine starts.

4.STARTER MOTOR ACTIVATION

Check that the starter motor operates.

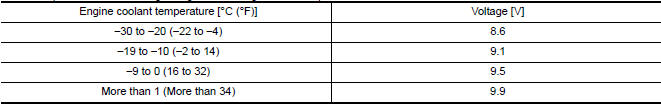

5.COMPARISON BETWEEN ENGINE COOLANT AND CRANKING VOLTAGE

Compare the engine coolant temperature and verify the cranking voltage is within specifications.

Minimum Specification of Cranking Voltage Referencing Coolant Temperature

6.STARTER OPERATION

Check the starter operation.

7."B" TERMINAL CIRCUIT INSPECTION

Check "B" terminal circuit.

8."S" CONNECTOR CIRCUIT INSPECTION

Check "S" connector circuit.

9.ENGINE ROTATION STATUS

Check that the engine can be rotated by hand.

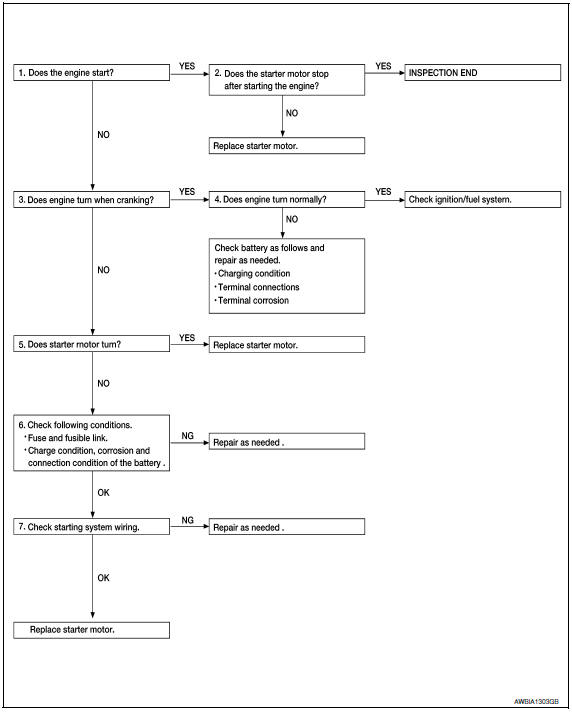

Work Flow (Without GR8-1200 NI)

OVERALL SEQUENCE

DETAILED FLOW

NOTE: If any malfunction is found, immediately disconnect the battery cable from the negative terminal.

1.CHECK ENGINE START

Crank the engine and check that the engine starts.

2.CHECK THAT THE STARTER MOTOR STOPS

Check that the starter motor stops after starting the engine.

3.CHECK THAT THE ENGINE TURNS WHEN CRANKING

Check that the engine turns when cranking.

4.CHECK THE ENGINE SPEED WHEN CRANKING

Check that the engine speed is not low when cranking.

5.CHECK STARTER MOTOR ACTIVATION

Check that the starter motor runs at cranking.

6.CHECK POWER SUPPLY CIRCUIT

Check the following conditions:

- Fuse and fusible link

- Charge condition, corrosion and connection of the battery

7.CHECK STARTING SYSTEM WIRING

Check the following:

- "B" terminal circuit. Refer to STR-9, "Diagnosis Procedure".

- "S" terminal circuit

Starting system

Starting system

...

System description

System description

STARTING SYSTEM

System Diagram

System Description

The starter motor plunger closes and provides a closed circuit between the

battery and the starter motor. The starter motor is grounded to the ...

Other materials:

Lifting sensor (rear)

Description

The lifting sensor (rear) is installed to the seat frame.

The pulse signal is input to the driver seat control unit when the

lifting (rear) is operated.

The driver seat control unit counts the pulse and calculates the lifting

(rear) amount of the seat.

Component Function ...

B261A push-button ignition switch

Description

IPDM E/R transmits the push-button ignition switch status via CAN

communication to BCM. BCM receives

push-button ignition switch status by hardwire input. BCM compares the 2 signals

for mismatch.

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC B261A is displayed with DTC U1000, ...

Wiring diagram

ENGINE CONTROL SYSTEM

Wiring Diagram

...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0071