Nissan Maxima Service and Repair Manual: P1778 step motor

Description

-

The step motor changes the step by turning 4 coils ON/OFF according to the signal from TCM. As a result, the flow of line pressure to primary pulley is changed and pulley ratio is controlled.

-

This diagnosis item is detected when the electrical system is OK, but the mechanical system is NG.

-

This diagnosis item is detected when the state of the changing of the speed mechanism in the unit does not operate normally.

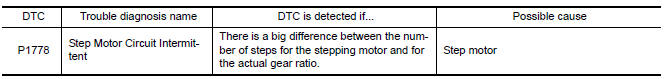

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

-

Always drive vehicle at a safe speed.

-

Before starting "DTC CONFIRMATION PROCEDURE", confirm "Hi" or "Mid" or "Low" fixation by "PRI SPEED" and "VEHICLE SPEED" in "Data Monitor".

-

If hi-geared fixation occurred, go to TM-112, "Diagnosis Procedure".

NOTE: Immediately after performing any "DTC CONFIRMATION PROCEDURE", always turn ignition switch OFF.

Then wait at least 10 seconds before performing the next test.

1.CHECK DTC DETECTION

With CONSULT

With CONSULT

-

Turn ignition switch ON.

-

Select "Data Monitor" in "TRANSMISSION".

-

Check that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN : 1.0 - 2.0 V

If it is out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to increase the voltage (cool down the fluid)

4. Start engine and maintain the following conditions for at least 30 consecutive seconds.

Start test from 0 km/h (0 MPH)

Constant acceleration : Keep 30 seconds or more

VEHICLE SPEED : 10 km/h (6 MPH) or more

ACC PEDAL OPEN : More than 1.0/8

RANGE : "D" position

ENG SPEED : 450 rpm or more

With GST

With GST

Follow the procedure "With CONSULT".

Diagnosis Procedure

1.CHECK STEP MOTOR SYSTEM

Check step motor system. Refer to TM-109, "DTC Logic".

2.CHECK PRIMARY SPEED SENSOR SYSTEM

Check primary speed sensor system. Refer to TM-57, "DTC Logic".

3.CHECK SECONDARY SPEED SENSOR SYSTEM

Check secondary speed sensor system. Refer to TM-60, "DTC Logic".

4.DETECT MALFUNCTIONING ITEMS

Check TCM connector pin terminals for damage or loose connection with harness connector.

P1777 step motor

P1777 step motor

Description

The step motor changes the step by turning 4 coils ON/OFF

according to the signal from TCM. As a result, the

flow of line pressure to primary pulley is changed and pulley ratio is

c ...

Shift position indicator circuit

Shift position indicator circuit

Description

TCM sends position indicator signals to

combination meter via CAN communication line.

The selector lever position is indicated on the

shift position indica ...

Other materials:

Outside the vehicle

The maintenance items listed here should be

performed from time to time, unless otherwise

specified.

Doors and engine hood: Check that the doors

and engine hood operate properly. Also ensure

that all latches lock securely. Lubricate hinges,

latches, latch pins, rollers and links if necessary ...

Rear door glass

Exploded View

Door glass run

Door panel

Window motor

Regulator assembly

Partition glass run

Partition glass

Partition sash

Door glass

Removal and Installation

REMOVAL

Remove the rear door finisher. Refer to INT-21, "Removal and

Installation".

Position the vap ...

Both side headlamps (LO) are not turned on

Description

The headlamps (both sides) do not turn ON in any lighting switch setting.

Diagnosis Procedure

1.CHECK COMBINATION SWITCH (LIGHTING AND TURN SIGNAL SWITCH)

Check the combination switch (lighting and turn signal switch).

2.CHECK HEADLAMP (LO) REQUEST SIGNAL INPUT

CONSULT DATA MONITOR ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0114