Nissan Maxima Service and Repair Manual: P1777 step motor

Description

The step motor changes the step by turning 4 coils ON/OFF according to the signal from TCM. As a result, the flow of line pressure to primary pulley is changed and pulley ratio is controlled.

DTC Logic

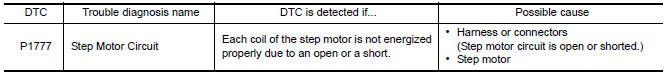

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION: Always drive vehicle at a safe speed.

NOTE: Immediately after performing any "DTC CONFIRMATION PROCEDURE", always turn ignition switch OFF.

Then wait at least 10 seconds before performing the next test.

1.CHECK DTC DETECTION

With CONSULT

With CONSULT

-

Start engine.

-

Drive vehicle for at least 5 consecutive seconds.

-

Perform "Self Diagnostic Results" in "TRANSMISSION".

With GST

With GST

Follow the procedure "With CONSULT".

Diagnosis Procedure

Regarding Wiring Diagram information, refer to TM-126, "Wiring Diagram".

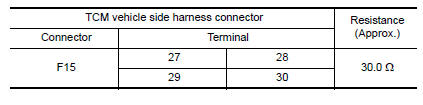

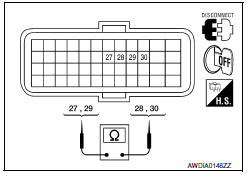

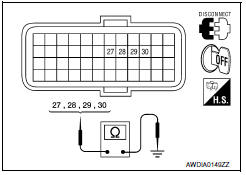

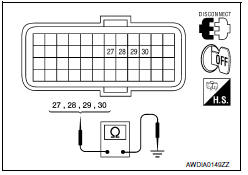

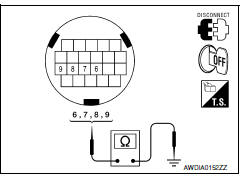

1.CHECK STEP MOTOR CIRCUIT

-

Turn ignition switch OFF.

-

Disconnect TCM connector.

-

Check resistance between TCM vehicle side harness connector terminals.

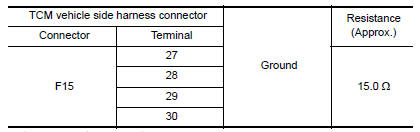

4. Check resistance between TCM vehicle side harness connector terminals and ground.

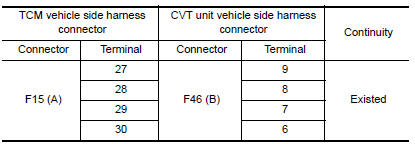

2.CHECK HARNESS BETWEEN TCM AND CVT UNIT (STEP MOTOR) (PART 1)

-

Disconnect CVT unit connector.

-

Check continuity between TCM vehicle side harness connector terminals and CVT unit vehicle side harness connector terminals.

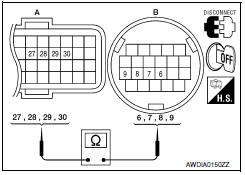

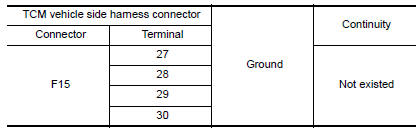

3.CHECK HARNESS BETWEEN TCM AND CVT UNIT (STEP MOTOR) (PART 2)

Check continuity between TCM vehicle side harness connector terminals and ground.

4.CHECK STEP MOTOR

Check step motor. Refer to TM-111, "Component Inspection (Step Motor)".

5.DETECT MALFUNCTIONING ITEMS

Check TCM connector pin terminals for damage or loose connection with harness connector.

Component Inspection (Step Motor)

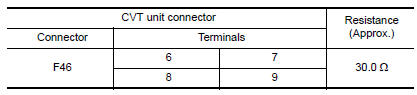

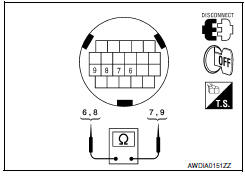

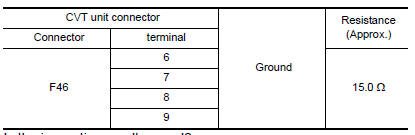

1.CHECK STEP MOTOR

1. Check resistance between CVT unit connector terminals.

2. Check resistance between CVT unit connector terminals and ground.

P1745 line pressure control

P1745 line pressure control

Description

The line pressure solenoid valve regulates the oil pump

discharge pressure to suit the driving condition in

response to a signal sent from the TCM.

DTC Logic

DTC DETECTION LOGIC

...

P1778 step motor

P1778 step motor

Description

The step motor changes the step by turning 4

coils ON/OFF according to the signal from TCM. As a result,

the flow of line pressure to primary pulley is changed and pulle ...

Other materials:

Air Cleaner And Air Duct

Removal and Installation

Air duct hose and resonator assembly

Front air duct

Air cleaner case (lower)

Grommets

Air cleaner case mounting bracket

Bracket

Air cleaner filter

Air cleaner case (upper)

Mass air flow sensor

To electric throttle control

actuator

...

Can communication system

Component Parts Location

ABS actuator and electric unit (control

unit) E26

TCM F15

ECM E10

4. IPDM E/R E17

BCM M19

Combination meter M24

Data link connector M22

Steering angle sensor M53

Driver seat control unit B203

...

Sunroof motor assembly

Wiring Diagram

...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0056