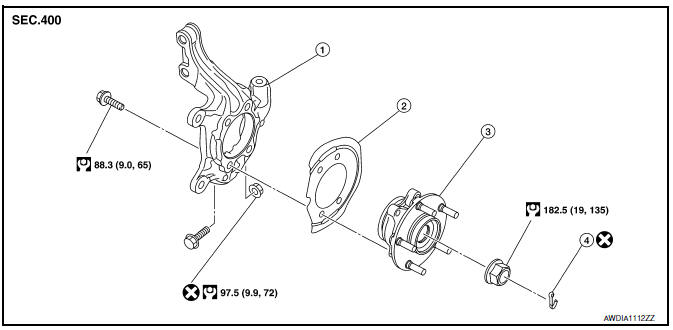

Nissan Maxima Service and Repair Manual: Front wheel hub

Removal and Installation

- Steering knuckle

- Splash guard

- Wheel hub and bearing assembly

- Cotter pin

REMOVAL

- Remove wheel and tire using power tool. Refer to WT-60, "Adjustment".

- Remove wheel sensor from steering knuckle. Refer to BRC-102,

"Removal and Installation - Front Wheel Sensor".

CAUTION: Do not pull on wheel sensor harness. - Remove brake hose lock plate from strut assembly.

- Remove brake caliper torque member bolts using power tool leaving

brake hose attached, then remove disc rotor. Reposition caliper aside

with wire. Refer to BR-32, "Removal and Installation of Brake Caliper and

Rotor".

NOTE: Avoid depressing brake pedal while brake caliper is removed. - Remove cotter pin, then loosen lock nut from drive shaft using power tool.

- Using a piece of wood and a hammer, tap on lock nut to disengage drive shaft from wheel hub.

CAUTION:

- Do not place drive shaft joint at an extreme angle. Also be careful not to overextend slide joint.

- Do not allow drive shaft to hang down without support.

NOTE: Use suitable puller if drive shaft cannot be separated from wheel hub and bearing assembly.

- Remove wheel hub and bearing assembly bolts using power tool.

- Remove splash guard and wheel hub and bearing assembly from steering knuckle.

INSPECTION AFTER REMOVAL

Check for deformity, cracks and damage on each part, replace if necessa

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse cotter pin.

- Do not reuse wheel hub lock nut.

- When installing wheel hub and bearing assembly to steering knuckle, align cutout in toner ring cover with wheel sensor mounting hole in steering knuckle.

Front drive shaft

Front drive shaft

Removal and Installation (LH)

Drive shaft

Cotter pin

REMOVAL

Remove wheel and tire using power tool. Refer to WT-60, "Adjustment".

Remove wheel sensor from steering knu ...

Other materials:

System maintenance

The sensor A is located behind the lower grille

of the front bumper.

To keep the system operating properly, be sure to

observe the following:

Always keep the sensor area of the front

bumper clean.

Do not strike or damage the areas around

the sensor.

Do not cover or attach st ...

Unlocking doors

1. Carry the Intelligent Key.

2. Push the door handle request switch.

3. The door on which the request switch was

pressed will unlock and the hazard warning

lights flash once, the outside buzzer sounds

once, and the front and tail lights will turn on

for 30 seconds.

4. Push the door ...

Steering gear and linkage

Exploded View

Outer socket

Boot clamp

Boot

Inner socket

Boot clamp

SSPS valve (part of gear assembly)

Gear assembly Front Three Bond 1111B or equivalent

Disassembly

Remove outer socket locknut and outer socket.

Remove boot clamps and boot. CAUTION:

Do not reuse boot ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0073