Nissan Maxima Service and Repair Manual: Front drive shaft

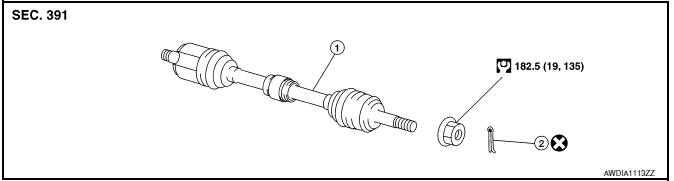

Removal and Installation (LH)

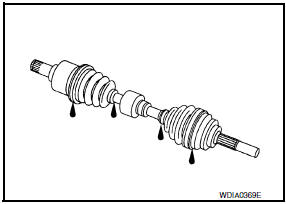

- Drive shaft

- Cotter pin

REMOVAL

- Remove wheel and tire using power tool. Refer to WT-60, "Adjustment".

- Remove wheel sensor from steering knuckle. Refer to BRC-102,

"Removal and Installation - Front Wheel Sensor".

CAUTION: Do not pull on wheel sensor harness.

- Remove brake hose lock plate from strut assembly.

- Remove brake caliper torque member bolts using power tool leaving

brake hose attached, then remove disc rotor. Reposition caliper aside

with wire. Refer to BR-32, "Removal and Installation of Brake Caliper and

Rotor".

NOTE: Avoid depressing brake pedal while brake caliper is removed.

- Remove cotter pin, then loosen lock nut from drive shaft using power tool.

- . Remove lower strut bolts and nuts using power tool. Refer to FSU-13, "Exploded View".

- Using a piece of wood and a hammer, tap on lock nut to disengage drive shaft from wheel hub.

CAUTION:

- Do not place drive shaft joint at an extreme angle. Also be careful not to overextend slide joint.

- Do not allow drive shaft to hang down without support.

NOTE: Use suitable puller if drive shaft cannot be separated from wheel hub and bearing assembly.

- Remove drive shaft from transaxle assembly.

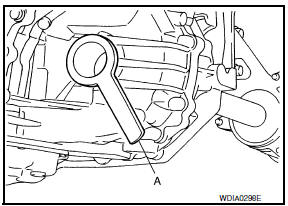

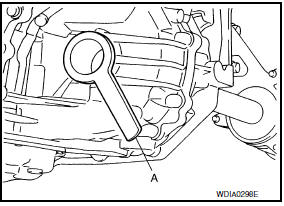

- Use Tool (A) and sliding hammer (B) while inserting tip of tool between housing and transaxle assembly.

CAUTION: Do not place drive shaft joint at an extreme angle when removing drive shaft. Also be careful not to overextend slide joint.

Tool number (A) : KV40107500 ( - )

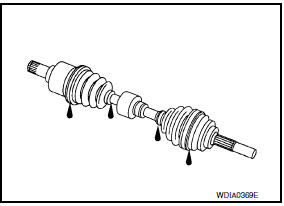

INSPECTION AFTER REMO

- Move joint up/down, left/right, and in axial direction. Check for any rough movement or significant looseness.

- Check boot for cracks or other damage, and for grease leakage.

- If damaged, disassemble drive shaft to verify damage, and repair or replace as necessary.

INSTALLATION

Installation is in the reverse order of removal. Note the following:

CAUTION: Do not reuse cotter pin.

- Install new circlip on drive shaft in the circular clip groove on

transaxle side. Refer to FAX-13, "Disassembly and Assembly (LH)".

CAUTION: Make sure the new circlip on the drive shaft is securely fastened. - In order to prevent damage to differential side oil seal, place Tool (A) onto oil seal before inserting drive shaft as shown. Slide drive shaft into slide joint and tap with a hammer to install securely.

Tool number (A) : KV38107900 ( - )

CAUTION: Make sure that circlip is completely engaged.

INSPECTION AFTER INSTALLATION

- Check wheel alignment. Refer to FSU-6, "Inspection and Adjustment".

- Adjust neutral position of steering angle sensor. Refer to BRC-6, "ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Special Repair Requirement".

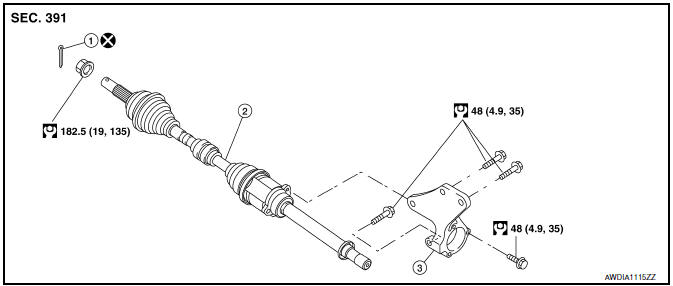

Removal and Installation (RH)

- Cotter pin

- Drive shaft

- Support bearing bracket

REMOVAL

- Remove wheel and tire using power tool. Refer to WT-60, "Adjustment".

- Remove wheel sensor from steering knuckle. Refer to BRC-102,

"Removal and Installation - Front Wheel Sensor".

CAUTION: Do not pull on wheel sensor harness. - Remove brake hose lock plate from strut assembly.

- Remove brake caliper torque member bolts using power tool leaving

brake hose attached, then remove disc rotor. Reposition caliper aside

with wire. Refer to BR-32, "Removal and Installation of Brake Caliper and

Rotor".

NOTE: Avoid depressing brake pedal while brake caliper is removed. - Remove cotter pin, then loosen lock nut from drive shaft using power tool.

- Remove lower strut bolts and nuts using power tool. Refer to FSU-13, "Exploded View".

- Using a piece of wood and a hammer, tap on lock nut to disengage drive shaft from wheel hub.

CAUTION:

- Do not place drive shaft joint at an extreme angle. Also be careful not to overextend slide joint.

- Do not allow drive shaft to hang down without support.

NOTE: Use suitable puller if drive shaft cannot be separated from wheel hub and bearing assembly.

- Remove bearing housing to support bearing bracket bolts.

- Remove drive shaft from transaxle assembly.

- Use Tool (A) and sliding hammer (B) while inserting tip of tool between housing and transaxle assembly.

CAUTION: Do not place drive shaft joint at an extreme angle when removing drive shaft. Also be careful not to overextend slide joint.

Tool number (A) : KV40107500 ( - )

- If necessary, remove the support bearing bracket.

- Remove front exhaust tube. Refer to EX-5, "Removal and Installation".

INSPECTION AFTER REMOVAL

- Move joint up/down, left/right, and in axial direction. Check for any rough movement or significant looseness.

- Check boot for cracks or other damage, and for grease leakage.

- If damaged, disassemble drive shaft to verify damage, and repair or replace as necessary

INSTALLATION

Installation is in the reverse order of removal. Note the following:

CAUTION: Do not reuse cotter pin.

- Install new circlip on drive shaft in the circular clip groove on transaxle side. Refer to FAX-19, "Disassembly and Assembly (RH)".

CAUTION: Make sure the new circlip on the drive shaft is securely fastened.

- In order to prevent damage to differential side oil seal, place Tool (A) onto oil seal before inserting drive shaft as shown. Slide drive shaft into slide joint and tap with a hammer to install securely.

Tool number (A) : KV38107900 ( - )

CAUTION: Make sure that circlip is completely engaged.

- When installing support bearing bracket, hand tighten the bolts, then tighten to specified torque.

INSPECTION AFTER INSTALLATION

- Check wheel alignment. Refer to FSU-6, "Inspection and Adjustment".

- Adjust neutral position of steering angle sensor. Refer to BRC-6, "ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Special Repair Requirement".

Front wheel hub

Front wheel hub

Removal and Installation

Steering knuckle

Splash guard

Wheel hub and bearing assembly

Cotter pin

REMOVAL

Remove wheel and tire using power tool. Refer to ...

Unit disassembly and assembly

Unit disassembly and assembly

FRONT DRIVE SHAFT

Disassembly and Assembly (LH)

Circlip

Dust shield

Housing

Snap ring

Spider assembly

Stopper ring

Boot band

Boot

Shaft

D ...

Other materials:

Preparation

Special Service Tool

The actual shapes of the tools may differ from those illustrated here.

Commercial Service Tool

...

Diagnosis system (meter)

Diagnosis Description

SELF-DIAGNOSIS MODE

Odo/trip meter and information display segment operation can be

checked in self-diagnosis mode.

Meters/gauges can be checked in self-diagnosis mode.

OPERATION PROCEDURE

Turn the ignition switch OFF.

While pushing the odo/trip meter switch, ...

Wiring diagram

MONOCHROME DISPLAY

Wiring Diagram - With BOSE Audio System

...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0074