Nissan Maxima Service and Repair Manual: Unit disassembly and assembly

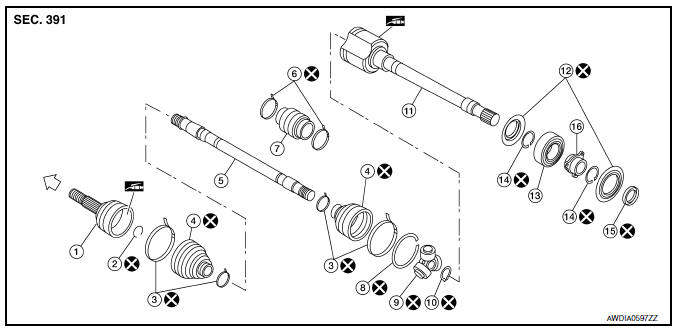

FRONT DRIVE SHAFT

Disassembly and Assembly (LH)

- Circlip

- Dust shield

- Housing

- Snap ring

- Spider assembly

- Stopper ring

- Boot band

- Boot

- Shaft

- Damper band

- Dynamic damper

- Circlip

- . Joint sub-assembly

: Wheel side

: Wheel side

: Fill using NISSAN Genuine grease or

equivalent.

: Fill using NISSAN Genuine grease or

equivalent.

DISASSEMBLY

Transaxle Side

- Mount front drive shaft in a vise.

CAUTION: When mounting shaft in a vise, always use copper or aluminum plates between vise and shaft. - Remove boot bands and slide the boot back.

- Remove circlip and dust shield from slide joint housing.

- Put matching marks on slide joint housing and shaft before separating slide joint assembly.

- Remove stopper ring with a suitable tool, then pull out slide joint housing.

- Put matching marks on spider assembly and shaft.

- Remove snap ring using a suitable tool, then remove spider assembly from shaft.

- Remove boot from shaft.

- Clean the old grease off of the slide joint assembly.

Wheel Side

- Mount the front drive shaft in a vise.

CAUTION: When mounting shaft in a vise, always use copper or aluminum plates between vise and shaft.

- Remove boot bands and slide the boot back.

- Screw a sliding hammer or suitable tool 30 mm (1.18 in) or more into threaded part of joint sub-assembly. Pull joint sub-assembly out of shaft.

CAUTION:

- Align sliding hammer or suitable tool and drive shaft then remove joint sub-assembly by pulling directly.

- If joint sub-assembly cannot be removed after five or more unsuccessful attempts, replace the entire drive shaft assembly.

- Remove boot from shaft.

- Remove circlip from shaft.

- While rotating ball cage, clean the old grease off of the joint sub-assembly.

Damper

- Remove damper bands, then remove damper from shaft.

INSPECTION AFTER DISASSEMBLY

Shaft

- Replace shaft if there is bending, cracking, or other damage.

Joint Sub-assembly

- Make sure there is no rough rotation or unusual axial looseness.

- Make sure there is no foreign material inside joint sub-assembly.

- Check joint sub-assembly for compression scars, cracks or fractures.

CAUTION: If there are any irregular conditions of joint sub-assembly components, replace the entire joint subassembly.

Slide Joint Housing

- Make sure there are no compression scars, cracks or fractures or unusual wear of ball rolling surface.

- Make sure there is no damage to shaft screws.

- Make sure there is no deformation of boot installation parts.

Ball Cage

- Make sure there are no compression scars, cracks, fractures of sliding surface.

Steel Ball

- Make sure there are no compression scars, cracks, fractures or unusual wear.

Inner Race

- Check ball sliding surface for compression scars, cracks or fractures.

- Make sure there is no damage to serrated part.

CAUTION: If there are any irregular conditions in the component, replace with a new set of joint sub-assembly, ball cage, steel ball and inner race.

Damper

- Check damper for cracks or wear. Install damper with new damper bands.

ASSEMBLY

Transaxle Side

- Install new boot and new small boot band on shaft.

CAUTION:

- Cover drive shaft serration with tape to prevent damage to boot during installation.

- Do not reuse boot band and boot.

- Remove protective tape wound around serrated part of shaft.

- Install spider assembly securely, making sure the matching marks which were made during disassembly are properly aligned.

- Install new snap ring using a suitable tool.

CAUTION: Do not reuse snap ring. - Pack drive shaft with specified amount of new grease (Genuine NISSAN Grease or equivalent).

- Install new stopper ring to housing of slide joint assembly.

CAUTION: Do not reuse stopper ring. - After installation, pull shaft to check engagement between slide joint assembly and stopper ring.

- Install boot securely into grooves (indicated by * marks) as shown.

CAUTION:

- - If there is grease on boot mounting surfaces (indicated by * marks) of shaft and housing, boot may come off. Clean all grease from surfaces.

- - Do not reuse boot.

- Make sure boot installation length (L) is the length specified below. Insert a suitable tool into the large end of boot. Bleed air from boot to prevent boot deformation.

CAUTION:

- Boot may break if boot installation length is less than standard value.

- Be careful that the tool does not contact inside surface of boot.

- Secure large end of boot with new boot band as shown.

- Put boot band in groove of drive shaft boot. Then insert pawls into holes.

CAUTION: Do not reuse boot bands.

NOTE: Insert projection (A) and guide slit (B).

: Pawl

: Pawl

- Pinch projection on boot band with suitable pliers to tighten band.

- Insert tip of band below end of pawl.

: Pawl

: Pawl

- Install new small boot band securely using Tool.

Tool number : KV40107300 ( - )

CAUTION:

- Do not reuse boot bands.

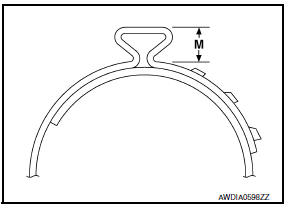

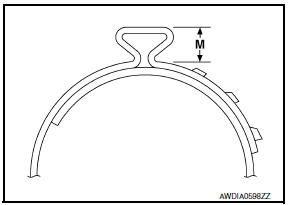

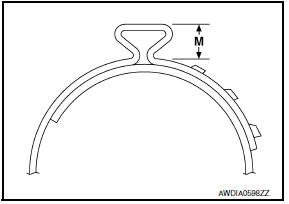

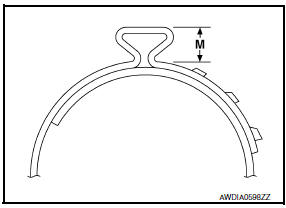

- Secure boot band so that dimension (M) meets specification as shown.

Dimension (M) : Refer to FAX-27, "Boot Bands".

- Install new dust shield to slide joint housing.

CAUTION: Do not reuse dust shield. - After installing housing and shaft, make sure boot position is correct. If boot position is not correct, remove old boot bands then reposition the boot and secure with new boot bands.

Wheel Side

- Add grease (Genuine NISSAN Grease or equivalent) into joint sub-assembly serration hole until grease begins to ooze from ball groove and serration hole. After inserting grease, use a shop cloth to wipe off old grease that has oozed out.

- Cover serrated part of shaft with tape. Install new boot band and

boot to shaft. Be careful not to damage boot.

CAUTION: Do not reuse boot band and boot. - Remove protective tape wound around serrated part of shaft.

- Attach new circlip to shaft. The circlip must fit securely into shaft

groove. Attach nut to joint sub-assembly.

Use a suitable tool to press-fit.

CAUTION: Do not reuse circlip.

- Insert the amount of new grease (Genuine NISSAN Grease or equivalent) listed below into housing from large end of boot.

- Install boot securely into grooves (indicated by * marks) as shown.

CAUTION:

- If there is grease on boot mounting surfaces (indicated by

* marks) of shaft and housing, boot may come off.

Remove all grease from surfaces.

- Do not reuse boot.

- Make sure boot installation length (L) is the specified length

indicated below. Insert a suitable tool into the large end of boot.

Bleed air from boot to prevent boot deformation.

Boot installation length (L) : Refer to FAX-26, "Drive Shaft".

CAUTION:

- Boot may break if boot installation length is less than standard value.

- Be careful that the tool does not contact inside surface of boot.

- Install new large and small boot bands securely using Tool.

Tool number : KV40107300 ( - )

CAUTION:

- Do not reuse boot bands.

- Secure boot band so that dimension (M) meets specification as shown.

Dimension (M) : Refer to FAX-27, "Boot Bands".

- After installing housing and shaft, rotate boot to check whether or not the actual position is correct. If boot position is not correct, remove old boot bands then reposition the boot and secure with new boot bands.

Damper

- Use new damper bands for installation.

CAUTION: Do not reuse damper bands. - Install damper from stationary-joint side while holding it securely.

(A) : Refer to FAX-26, "Dynamic Damper".

(B) : Refer to FAX-26, "Dynamic

Damper".

Disassembly and Assembly (RH)

- Joint sub-assembly

- Circlip

- Boot band

- Boot

- Shaft

- Damper band

- Dynamic damper

- Stopper ring

- Spider assembly

- Snap ring

- Housing

- Dust shield

- Support bearing

- Snap ring

- Dust shield

- Bearing housing

: Wheel side

: Wheel side

: Fill using NISSAN Genuine grease or

equivalent.

: Fill using NISSAN Genuine grease or

equivalent.

DISASSEMBLY

Transaxle Side

- Press shaft in a vise.

CAUTION: When retaining shaft in a vise, always use copper or aluminum plates between vise and shaft. - Remove circlip and dust shield from slide joint housing.

- Remove boot bands and slide the boot back.

- Put matching marks on slide joint housing and shaft before separating slide joint housing.

- Remove stopper ring using a suitable tool, then pull out slide joint housing.

- Put matching marks on spider assembly and shaft.

- Remove snap ring using a suitable tool, then remove spider assembly from shaft.

- Remove boot from shaft.

- Clean old grease off of the slide joint housing.

Wheel Side

- Mount the front drive shaft in a vise.

CAUTION: When mounting shaft in a vise, always use copper or aluminum plates between vise and shaft. - Remove boot bands and slide the boot back.

- Screw a sliding hammer or suitable tool 30 mm (1.18 in) or more into threaded part of joint sub-assembly. Pull joint sub-assembly out of shaft.

CAUTION:

- Align sliding hammer or suitable tool and drive shaft then remove joint sub-assembly by pulling directly.

- If joint sub-assembly cannot be removed after five or more unsuccessful attempts, replace the entire drive shaft assembly.

- Remove boot from shaft.

- Remove circlip from shaft.

Support Bearing

- Remove dust shields from slide joint assembly using a suitable tool.

- Remove snap ring using a suitable tool.

- Press support bearing assembly off slide joint assembly using a suitable tool.

- Separate support bearing from bracket using a suitabe tool.

Damper

- Remove damper bands, then remove damper from shaft.

INSPECTION AFTER DISASSEMBLY

Shaft

- Replace shaft if there is any bending, cracking, or other damage.

Joint Sub-assembly

- Make sure there is no rough rotation or unusual axial looseness.

- Make sure there is no foreign material inside joint sub-assembly.

- Check joint sub-assembly for compression scars, cracks or fractures.

CAUTION: If there are any irregular conditions of joint sub-assembly components, replace the entire joint subassembly.

Sliding Joint Housing and Spider Assembly

- If roller surface of spider assembly has scratches or wear, replace housing and spider assembly.

NOTE: Housing and spider assembly are components which are used as a set.

Support Bearing

- Make sure wheel bearing rolls freely and is free from noise, cracks, pitting or wear.

Damper

- Check damper for cracks or wear. Install damper with new damper bands

ASSEMBLY

Transaxle Side

- Cover serrated part of shaft with tape. Install new boot and boot

band onto shaft. Be careful not to damage boot.

CAUTION: Do not reuse boot band and boot. - Remove protective tape wound around serrated part of shaft.

- Install spider assembly securely, making sure the matching marks which were made during disassembly are properly aligned.

- Install new snap ring using a suitable tool.

CAUTION: Do not reuse snap ring. - Pack drive shaft with specified amount of grease (Genuine NISSAN Grease or equivalent).

Grease quantity : Refer to FAX-26, "Drive Shaft".

- Install new stopper ring to slide joint assembly. CAUTION: Do not reuse stopper ring.

- After installation, pull shaft to check engagement between slide joint assembly and stopper ring.

- Install boot securely into grooves (indicated by * marks) as shown.

CAUTION:

- - If there is grease on boot mounting surfaces (indicated by *

marks) of shaft and housing, boot may come off.

Remove all grease from surfaces.

- Do not reuse boot.

- Make sure boot installation length (L) is the length indicated below. Insert a suitable tool into the large end of boot. Bleed air from boot to prevent boot deformation.

Boot installation length (L) : Refer to FAX-26, "Drive Shaft".

CAUTION:

- Boot may break if boot installation length is less than standard value.

- Be careful that the tool does not contact inside surface of boot.

- Secure large end of boot with new boot band as shown.

- Put boot band in groove of drive shaft boot. Then insert pawls into holes.

CAUTION: Do not reuse boot bands.

NOTE: Insert projection (A) and guide slit (B).

: Pawl

: Pawl

- Pinch projection on boot band with suitable pliers to tighten band.

- Insert tip of band below end of pawl.

: Pawl

: Pawl

- Install new small boot band securely using Tool.

Tool number : KV40107300 ( - )

CAUTION:

- - Do not reuse boot bands.

- Secure boot band so that dimension (M) meets specification as shown.

Dimension (M) : Refer to FAX-27, "Boot Bands"

- Install new dust shield to slide joint housing. CAUTION: Do not reuse dust shield.

- After installing housing and shaft, rotate boot to check whether or not the actual position is correct. If boot position is not correct, remove old boot bands then reposition the boot and secure with new boot bands.

Wheel Side

- Add grease (Genuine NISSAN Grease or equivalent) into joint sub-assembly serration hole until grease begins to ooze from ball groove and serration hole. After inserting grease, use a shop cloth to wipe off old grease that has oozed out.

- Cover serrated part of shaft with tape. Install new boot and boot

band onto shaft. Be careful not to damage boot.

CAUTION: Do not reuse boot band and boot. - Remove protective tape wound around serrated part of shaft.

- Attach new circlip to shaft. The circlip must fit securely into shaft

groove. Attach nut to joint sub-assembly.

Use a suitable tool to press-fit.

CAUTION: Do not reuse circlip. - Insert the amount of new grease (Genuine NISSAN Grease or equivalent) listed below into housing from large end of boot.

Grease quantity : Refer to FAX-26, "Drive Shaft".

- Install boot securely into grooves (indicated by * marks) as shown.

CAUTION:

- If there is grease on boot mounting surfaces (indicated by

* marks) of shaft and housing, boot may come off.

Remove all grease from surfaces.

- Do not reuse boot.

- Make sure boot installation length (L) is the specified length,

indicated below. Insert a suitable tool into the large end of boot.

Bleed air from boot to prevent boot deformation.

Boot installation length (L) : Refer to FAX-26, "Drive Shaft".

CAUTION:

- Boot may break if boot installation length is less than standard value.

- Be careful that the tool does not contact inside surface of boot.

- Install new large and small boot bands securely using Tool.

Tool number : KV40107300 ( -

CAUTION:

- - Do not reuse boot bands.

- Secure boot band so that dimension (M) meets specification as shown.

Dimension (M) : Refer to FAX-27, "Boot Bands".

- After installing housing and shaft, rotate boot to check whether or not the actual position is correct. If boot position is not correct, remove old boot bands then reposition the boot and secure with new boot band

Damper

- Use new damper bands for installation. CAUTION: Do not reuse damper bands.

- Install damper from stationary-joint side while holding it securely.

(A) : Refer to FAX-26, "Dynamic Damper".

(B) : Refer to FAX-26, "Dynamic

Damper".

Front drive shaft

Front drive shaft

Removal and Installation (LH)

Drive shaft

Cotter pin

REMOVAL

Remove wheel and tire using power tool. Refer to WT-60, "Adjustment".

Remove wheel sensor from steering knu ...

Service data and specifications (SDS)

Service data and specifications (SDS)

Wheel Bearing

Drive Shaft

*: Boot installation grooves

Dynamic Damper

NOTE: Measured from wheel side

Boot Bands

...

Other materials:

SRS air bag system

SRS Configuration

The air bag deploys if the air bag diagnosis sensor unit is activated while

the ignition switch is in the ON orSTART position.The collision modes

for which supplemental restraint systems are activated are different among the

SRS systems.For example, the driver air bag modu ...

Glove box assembly

Removal and Installation

REMOVAL

Using a suitable tool, gently remove the instrument panel side

finisher (RH).

Open the glove box door and then remove the glove box assembly

screws (A).

Remove the glove box assembly lower screws (A).

Disconnect the harness connectors, then rem ...

Wiring diagram

TIRE PRESSURE MONITORING SYSTEM

Wiring Diagram

...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0076