Nissan Maxima Service and Repair Manual: System description

REFRIGERATION SYSTEM

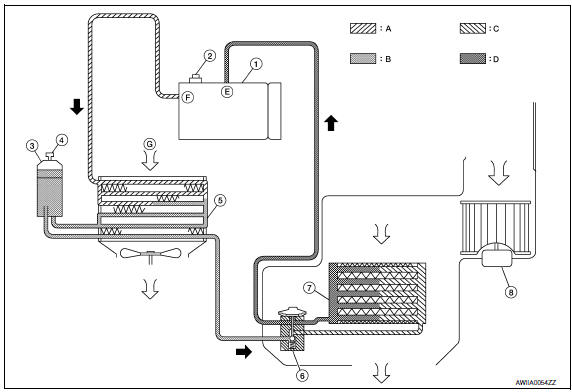

Refrigerant Cycle

Refrigerant flow

- Compressor

- Pressure relief valve

- Liquid tank

- Refrigerant pressure sensor

- Condenser

- Expansion valve

- Evaporator

- Blower motor

- High-pressure gas

- High-pressure liquid

- Low-pressure liquid

- Low-pressure gas

- Suction port

- Discharge port

- Outside air

The refrigerant from the compressor flows through the condenser with liquid tank, the evaporator and returns to the compressor. The refrigerant evaporation in the evaporator is controlled by an expansion valve.

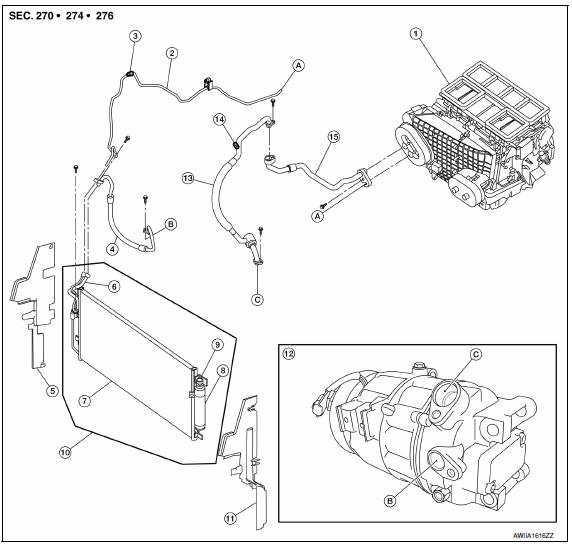

Component Part Location

- Heater and cooling unit assembly

- High-pressure pipe

- High-pressure A/C service valve

- High-pressure flexible hose

- Air deflector (RH)

- Junction pipe

- Condenser

- Liquid tank

- Refrigerant pressure sensor

- Condenser, liquid tank and refrigerant pressure sensor

- Air deflector (LH)

- Compressor

- Low-pressure flexible hose

- Low-pressure A/C service valve

- Low-pressure pipe

- High-pressure pipe to heater and cooling unit assembly

- . High-pressure flexible hose to compressor

- Low-pressure flexible hose to compressor

Refrigerant System Protection

Refrigerant pressure sensor

The refrigerant system is protected against excessively high or low pressures by the refrigerant pressure sensor, located on the condenser. If the system pressure rises above or falls below the specifications, the refrigerant pressure sensor detects the pressure inside the refrigerant line and sends the voltage signal to the ECM.

The ECM then ceases to supply power to the A/C relay which disengages and stops the compressor when pressure on the high pressure side (as detected by refrigerant pressure sensor) is over approximately 2,746 kPa (28 kg/cm2, 398 psi), or below approximately 120 kPa (1.22 kg/cm2, 17.4 psi).

Pressure Relief Valve

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system increases to an abnormal level [more than 3,727 kPa (38 kg/ cm2, 540 psi)], the release port on the pressure relief valve automatically opens and releases refrigerant into the atmosphere.

Preparation

Preparation

PREPARATION

Special Service Tool

The actual shapes of the tools may differ from those illustrated here.

HFC-134a (R-134a) Service Tool and Equipment

Do not mix HFC-134a (R-134a) refrigerant an ...

Basic inspection

Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

WITH COLOR DISPLAY

WITH COLOR DISPLAY : How to Perform Trouble Diagnosis For Quick And

Accurate Repair

WORK FLOW

1.LISTEN TO CUSTOMER COMPLAINT

Interview the cust ...

Other materials:

Inspection and adjustment

Preliminary Check

NOTE: The Signal Tech II Tool (J-50190) can be used

to perform the following functions. Refer to the Signal Tech II User Guide

for additional information.

Activate and display TPMS transmitter IDs

Display tire pressure reported by the TPMS transmitter

...

Air breather hose

Exploded View

Air cleaner case

Air breather hose

Transaxle assembly

Heater pipe

Clip

A. Paint mark

: Front

Removal and Installation

REMOVAL

Remove front air duct. Refer to EM-24, "Removal

and Installa ...

Main line between hvac and ABS circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative

terminal.

Check the following terminals and connectors for

damage, bend and loose connection (connector side

and harness side).

Harness connec ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0075