Nissan Maxima Service and Repair Manual: Insufficient cooling

Component Function Check

Symptom

- Insufficient cooling

- No cool air comes out. (Airflow volume is normal.)

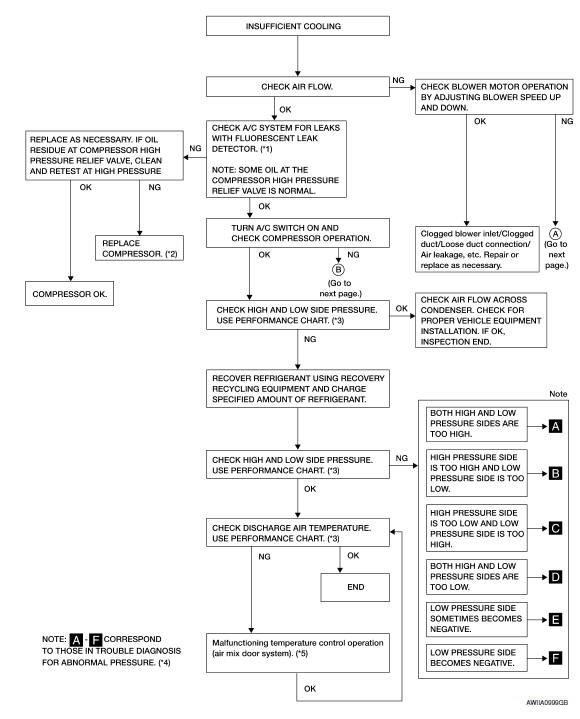

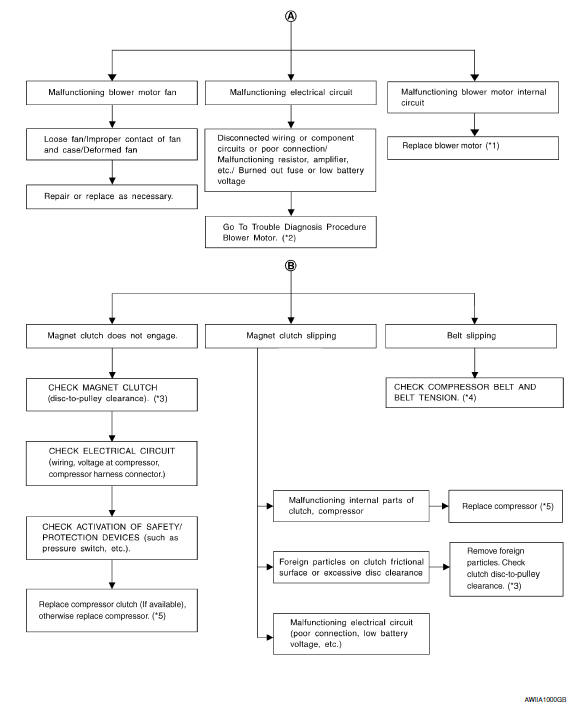

INSPECTION FLOW

1. CONFIRM SYMPTOM BY PERFORMING OPERATION CHECK - TEMPERATURE DECREASE

- Press the AUTO switch.

- Turn temperature control dial (driver side) counterclockwise until 18C (60F) is displayed.

- Check for cold air at discharge air outlets.

2. CHECK FOR ANY SYMPTOMS

Perform a complete operational check and check for any symptoms.

3. CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

4. CHECK DRIVE BELTS

Check compressor belt tension.

5.CHECK SETTING OF TEMPERATURE SETTING TRIMMER

Using CONSULT, check the setting of "TEMP SET CORRECT" on "WORK SUPPORT" of HVAC.

- Check that the temperature setting trimmer is set to "+ direction". NOTE: The control temperature can be set with the setting of the temperature setting trimmer.

- Set temperature control dial to "0".

6.CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT

- Using CONSULT, perform "SELF-DIAGNOSIS RESULTS" of HVAC.

- Check if any DTC No. is displayed in the trouble diagnosis results.

NOTE: If DTC is displayed along with DTC U1000 or U1010, first diagnose the DTC U1000 or U1010.

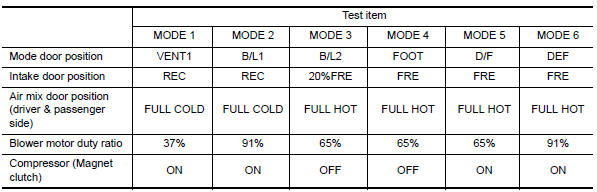

7.CHECK WITH ACTIVE TEST OF CONSULT

- Using CONSULT, perform "HVAC TEST""ACTIVE TEST" of HVAC to check each output device. Refer to HAC-26, "CONSULT Function". NOTE: Perform the ACTIVE TEST after starting the engine because the compressor is operating.

- Refer to the table and check the outlet, inlet, airflow temperature, blower motor control signal, magnet clutch operation, and air mix ratio. Visually check each operating condition, by listening for noise, touching air outlets with a hand, etc.

8. CHECK AIR MIX DOOR MOTOR OPERATION

Check and verify air mix door mechanism for smooth operation.

9. CHECK COOLING FAN MOTOR OPERATION

Check and verify cooling fan motor for smooth operation.

10. CHECK RECOVERY/RECYCLING EQUIPMENT BEFORE USAGE

Check recovery/recycling equipment before connecting to vehicle. Verify there is no pressure in the recovery/ recycling equipment by checking the gauges. If pressure exists, recover refrigerant from equipment lines.

11. CHECK REFRIGERANT PURITY

- Connect recovery/recycling equipment to vehicle.

- Confirm refrigerant purity in supply tank using recovery/recycling and refrigerant indentifier.

12. CHECK REFRIGERANT PRESSURE

Check refrigerant pressure with manifold gauge connected.

13. CHECK FOR EVAPORATOR FREEZE-UP

Start engine and run A/C. Check for evaporator freeze-up.

NOTE: Evaporator freeze up usually occurs at sustained highway speeds in hot, humid conditions with blend door at full cold and blower on low speed, after 1-3 hours of continuous driving.

14. CHECK AIR DUCTS

Check ducts for air leaks.

Diagnostic Work Flow

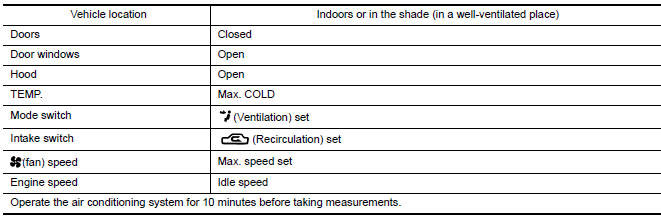

Performance Chart

TEST CONDITION

Testing must be performed as follows:

TEST READING

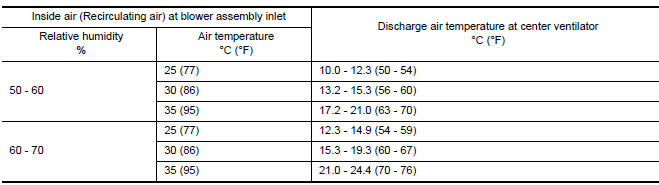

Recirculating-to-discharge Air Temperature Table

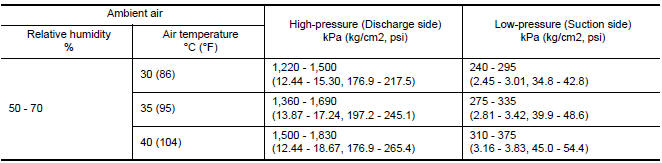

Ambient Air Temperature-to-operating Pressure Table

Insufficient heating

Insufficient heating

Component Function Check

Symptom

Insufficient heating

No warm air comes out. (Airflow volume is normal.)

INSPECTION FLOW

1. CONFIRM SYMPTOM BY PERFORMING OPERATION CHECK - TEMPERATURE INCRE ...

Other materials:

IPDM E/R (intelligent power distribution module engine room)

Reference Value

VALUES ON THE DIAGNOSIS TOOL

TERMINAL LAYOUT

PHYSICAL VALUES

Fail Safe

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible, IPDM E/R performs

fail-safe control. After CAN

communication recovers normally, it also re ...

Forward-facing child restraint installation using LATCH

For additional information, refer to all Warnings

and Cautions in the "Child safety" and "Child

restraints" sections of this manual before installing

a child restraint.

Do not use the lower anchors if the combined

weight of the child and the child restraint exceeds

65 lbs (29.5 kg). If the c ...

Precaution

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR

BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as "AIR BAG" and

"SEAT BELT PRE-TENSIONER", used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and fr ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.017