Nissan Maxima Service and Repair Manual: Magnet clutch

Description

SYSTEM DESCRIPTION

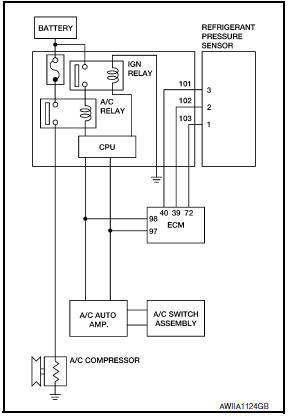

A/C auto amp. controls A/C compressor operation by ambient temperature and signal from ECM.

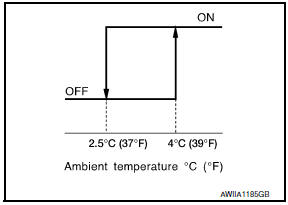

Low Temperature Protection Control A/C auto amp. will turn the A/C compressor ON or OFF as determined by a signal detected by ambient sensor.

When ambient temperature is greater than 4C (39F), the A/C compressor turns ON. The A/C compressor turns OFF when ambient temperature is less than 2.5C (37F).

Component Function Check

1.FUNCTION INSPECTIONS

- Press AUTO switch. AUTO is indicated on the display.

- Press the A/C switch.

- Check that the indicator of the A/C switch turns on. Check visually and by sound that the A/C compressor is operating. (The discharge air temperature or fan speed varies depending on the ambient temperature, in-vehicle temperature, and temperature setting.)

- Press the A/C switch again.

- Check that the indicator of the A/C switch turns OFF. Check visually and by sound that the A/C compressor stops.

Diagnosis Procedure

SYMPTOM: Magnet clutch does not engage when A/C switch is ON.

1.INSPECTION IN AUTO ACTIVE TEST MODE

Perform "AUTO ACTIVE TEST".

2.CHECK POWER SUPPLY FOR A/C COMPRESSOR

- Turn ignition switch OFF.

- Disconnect A/C compressor connector.

- Start engine and press A/C switch.

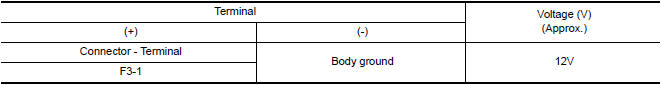

- Check voltage between A/C compressor harness connector F3 terminal 1 and ground.

3.CHECK FUSE

Check 10A fuse (No. 41) located in IPDM E/R.

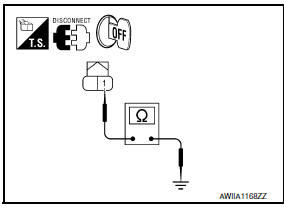

4.CHECK CIRCUIT CONTINUITY BETWEEN A/C RELAY IN IPDM E/R AND A/C COMPRESSOR

- Turn ignition switch OFF.

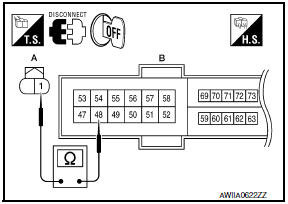

- Disconnect IPDM E/R connector F10 and A/C compressor connector F3.

- Check continuity between A/C compressor harness connector F3 (A) terminal 1 and IPDM E/R harness connector F10 (B) terminal 48.

1 - 48: Continuity should exist.

5.CHECK A/C COMPRESSOR CIRCUIT FOR SHORT

Check continuity between A/C compressor harness connector F3 terminal 1 and ground.

1 - Ground: Continuity should not exist.

6.CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT

- Using CONSULT, perform "SELF-DIAGNOSIS RESULTS" of HVAC.

- Check if any DTC No. is displayed in the self-diagnosis results.

NOTE: If DTC is displayed along with DTC U1000 or U1010, first diagnose the DTC U1000 or U1010.

7.CHECK A/C AUTO AMP. INPUT SIGNAL

Using CONSULT, check "On/Off" of "COMP REQ SIG" and "FAN REQ SIG" in "DATA MONITOR" of HVAC.

A/C SWITCH ON: COMP REQ SIG On

A/C SWITCH OFF: COMP REQ SIG Off

FAN CONTROL DIAL ON: FAN REQ SIG On

FAN CONTROL DIAL OFF: FAN REQ SIG Off

8.CHECK REFRIGERANT PRESSURE SENSOR

Check refrigerant pressure sensor.

Blower motor

Blower motor

Description

COMPONENT DESCRIPTION

Brush-less Motor

The blower motor utilizes a brush-less motor with a rotating magnet.

Quietness is improved over previous motors where the brush was

the point ...

A/C switch assembly signal circuit

A/C switch assembly signal circuit

Diagnosis Procedure

1.CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT

Using CONSULT, perform "SELF-DIAGNOSIS RESULTS" of HVAC.

Check if any DTC No. is displayed in the self-diagnosis results.

...

Other materials:

HVAC branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the A/C auto amp. for

damage, bend and loose connection (unit

side and connector side).

2.CHECK HARNESS FOR OPEN CIRCUI ...

Remove

Use the following procedure to remove the head

restraint/headrest:

1. Pull the head restraint/headrest up to the

highest position.

2. Push and hold the lock knob.

3. Remove the head restraint/headrest from

the seat.

4. Store the head restraint/headrest properly in

a secure place so i ...

Driver Attention Alert system limitations

WARNING

Listed below are the system limitations for

the Driver Attention Alert system. Failure

to operate the vehicle in accordance with

these system limitations could result in

serious injury or death.

The Driver Attention Alert system may

not operate properly and may not provide

an alert i ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0075