Nissan Maxima Service and Repair Manual: Blower motor

Description

COMPONENT DESCRIPTION

Brush-less Motor

The blower motor utilizes a brush-less motor with a rotating magnet.

Quietness is improved over previous motors where the brush was the point of contact and the coil rotated.

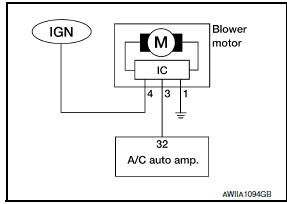

Blower Motor Circuit

Component Function Check

1.CHECK OPERATION

- Warm up the engine.

- Operate the fan control dial. Check that the fan speed and indicator are switched for all fan speeds.

Diagnosis Procedure

1.CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT

- Using CONSULT, perform "SELF-DIAGNOSIS RESULTS" of HVAC.

- Check if any DTC No. is displayed in the self-diagnosis results.

NOTE: If DTC is displayed along with DTC U1000 or U1010, first diagnose the DTC U1000 or U1010

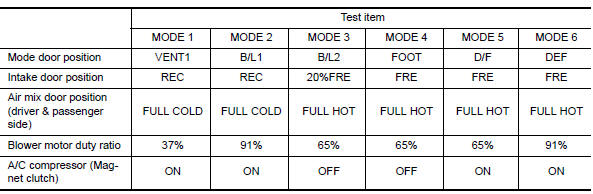

2.CHECK WITH ACTIVE TEST OF CONSULT

- Using CONSULT, perform "HVAC TEST""ACTIVE TEST" of HVAC to check each output device. Refer to HAC-129, "CONSULT Function". NOTE: Perform the ACTIVE TEST after starting the engine, because the A/C compressor is operating.

- Check that the blower motor control signal changes according to each indicator signal.

NOTE: Perform the inspection of each output device after starting the engine because the A/C compressor is operating.

3.CHECK FUSE

Check 15A fuses (Nos. 21 and 22) located in fuse block (J/B).

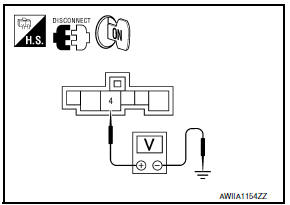

4.CHECK POWER SUPPLY FOR BLOWER MOTOR

- Turn ignition switch OFF.

- Disconnect blower motor connector.

- Turn ignition switch ON.

- Check voltage between blower motor harness connector M31 terminal 4 and ground.

4 - Ground: Battery voltage

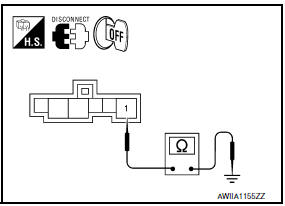

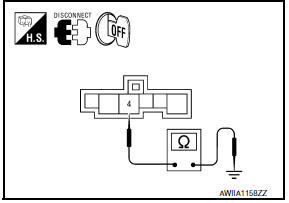

5.CHECK BLOWER MOTOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Check continuity between blower motor harness connector M31 terminal 1 and ground.

1 - Ground: Continuity should exist.

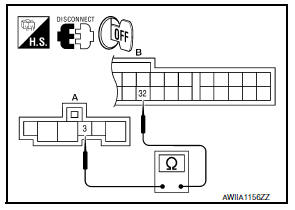

6.CHECK BLOWER MOTOR CIRCUIT CONTINUITY

- Disconnect A/C auto amp. connector.

- Check continuity between blower motor harness connector M31 (A) terminal 3 and A/C auto amp. harness connector M37 (B) terminal 32.

3 - 32: Continuity should exist.

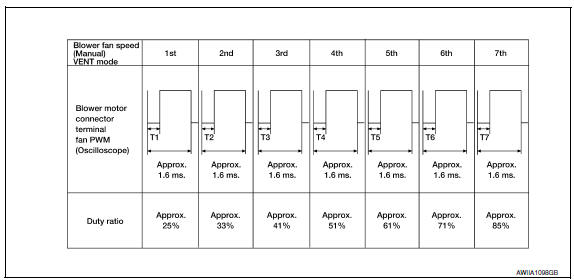

7.CHECK A/C AUTO AMP. OUTPUT SIGNAL

- Reconnect blower motor connector and A/C auto amp. connector.

- Turn ignition switch ON.

- Set MODE switch to the VENT position.

- Check the output waveform between blower motor harness connector M31 terminal 3 and ground using an oscilloscope, while varying the fan speed from 1 to 7.

8.REPLACE FUSES

- Replace fuses.

- Activate the blower motor.

9.CHECK BLOWER MOTOR POWER SUPPLY CIRCUIT FOR SHORT

- Turn ignition switch OFF.

- Disconnect blower motor harness connector.

- Check continuity between blower motor harness connector M31 terminal 4 and ground.

4 - Ground: Continuity should not exist.

10.CHECK POWER SUPPLY OF THE FRONT BLOWER MOTOR RELAY

- Turn the ignition switch OFF.

- Remove the front blower motor relay.

- Turn the ignition switch ON.

- Check the voltage between front blower motor relay harness connector J-4 terminals 2, 3 and ground.

2, 3 - Ground: Battery voltage

11.CHECK FRONT BLOWER MOTOR RELAY GROUND CIRCUIT

- Turn ignition switch OFF.

- Check continuity between front blower motor relay harness connector J-4 terminal 1 and ground.

1 - Ground: Continuity should exist.

12.CHECK BLOWER MOTOR SUPPLY CIRCUIT FOR OPEN

Check continuity between blower motor harness connector M31 terminal 4 and front blower motor relay harness connector J-4 terminal 5.

5 - 4: Continuity should exist.

B263D, B263E, B263F intake door motor

B263D, B263E, B263F intake door motor

Description

COMPONENT DESCRIPTION

Intake Door Motor

The intake door motor (1) is attached to the blower unit.

It rotates so that air is drawn from inlets set by the A/C auto

amp.

Motor ...

Magnet clutch

Magnet clutch

Description

SYSTEM DESCRIPTION

A/C auto amp. controls A/C compressor operation by ambient temperature and

signal from ECM.

Low Temperature Protection Control

A/C auto amp. will turn the A/C co ...

Other materials:

Steering switch

Description

When one of the steering wheel audio control switches is pushed, the

resistance in the steering wheel audio control switch circuit changes,

depending on which button is pushed.

Diagnosis Procedure

1.CHECK STEERING SWITCH RESISTANCE

Disconnect steering switch connector M88. ...

P0455 evap control system

DTC Logic

DTC DETECTION LOGIC

This diagnosis detects a very large leakage (fuel filler cap fell off etc.)

in EVAP system between the fuel tank

and EVAP canister purge volume control solenoid valve.

CAUTION:

Use only a genuine NISSAN fuel filler cap as a replacement. If

an ...

Front fog lamp

System Diagram

System Description

BCM (Body Control Module) controls front fog lamp operation.

IPDM E/R (Intelligent Power Distribution Module Engine Room)

operates front fog lamp according to CAN communication signals from BCM.

Combination meter operates front fog lamp indicator accor ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0074