Nissan Maxima Service and Repair Manual: Shift lock system

Description

The selector lever cannot be shifted from "P" position to any other position unless the ignition switch is in the ON position and the brake pedal is depressed.

Component Function Check

1. CHECK CVT SHIFT LOCK OPERATION

-

Turn ignition switch ON.

-

Move selector lever to "P" position.

-

Attempt to shift selector lever to any other position with brake pedal released.

2. CHECK CVT SHIFT LOCK OPERATION

Attempt to shift selector lever to any other position with brake pedal depressed.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to TM-134, "Wiring Diagram".

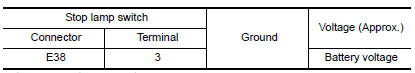

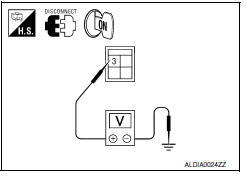

1. CHECK POWER SOURCE (STOP LAMP SWITCH)

-

Turn ignition switch OFF.

-

Disconnect stop lamp switch connector.

-

Check voltage between stop lamp switch connector E38 terminal 3 and ground.

2.CHECK STOP LAMP SWITCH

Check stop lamp switch. Refer to TM-118, "Component Inspection (Stop Lamp Switch)".

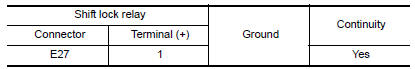

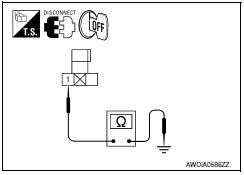

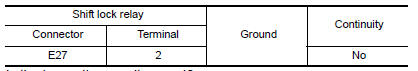

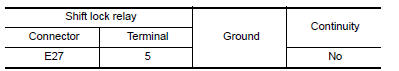

3.CHECK GROUND CIRCUIT (SHIFT LOCK RELAY)

-

Remove shift lock relay.

-

Check continuity between shift lock relay connector E27 terminal 1 and ground.

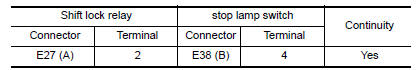

4.CHECK HARNESS BETWEEN SHIFT LOCK RELAY AND STOP LAMP SWITCH FOR OPEN

Check continuity between shift lock relay connector E27 (A) terminal 2 and stop lamp switch connector E38 (B) terminal 4.

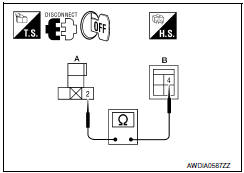

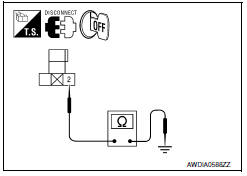

5.CHECK HARNESS BETWEEN SHIFT LOCK RELAY AND STOP LAMP SWITCH FOR SHORT CIRCUIT

Check continuity between shift lock relay connector E27 terminal 2 and ground.

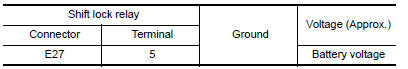

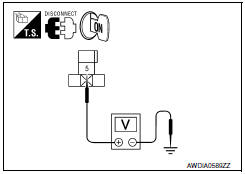

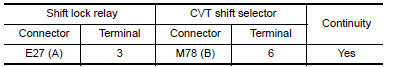

6.CHECK POWER SOURCE (SHIFT LOCK RELAY)

-

Turn ignition switch ON.

-

Check voltage between shift lock relay connector E27 terminal 5 and ground.

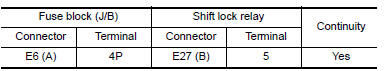

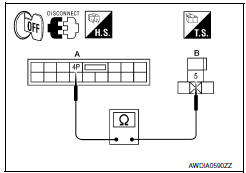

7.CHECK HARNESS BETWEEN FUSE BLOCK (J/B) AND SHIFT LOCK RELAY FOR OPEN

-

Turn ignition switch OFF.

-

Disconnect fuse block (J/B).

-

Check continuity between fuse block (J/B) connector E6 (A) terminal 4P and shift lock relay connector E27 (B) terminal 5.

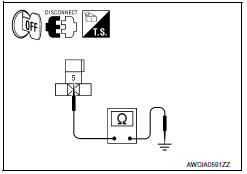

8.CHECK HARNESS BETWEEN FUSE BLOCK (J/B) AND SHIFT LOCK RELAY FOR SHORT CIRCUIT

Check continuity between shift lock relay connector E27 terminal 5 and ground.

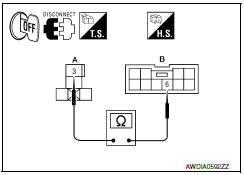

9.CHECK HARNESS BETWEEN SHIFT LOCK RELAY AND CVT SHIFT SELECTOR FOR OPEN

-

Disconnect CVT shift selector connector.

-

Check continuity between shift lock relay connector E27 (A) terminal

-

and CVT shift selector connector M78 (B) terminal 6.

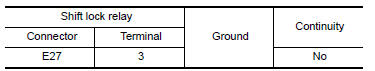

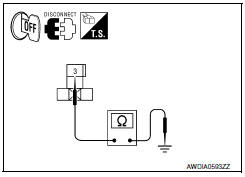

10.CHECK HARNESS BETWEEN SHIFT LOCK RELAY AND CVT SHIFT SELECTOR FOR SHORT CIRCUIT

Check continuity between shift lock relay connector E27 terminal 3 and ground.

11.CHECK SHIFT LOCK RELAY

Check shift lock relay. Refer to TM-118, "Component Inspection (Shift Lock Relay)".

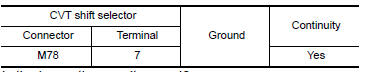

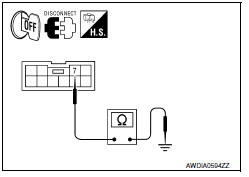

12.CHECK GROUND CIRCUIT (CVT SHIFT SELECTOR)

Check continuity between CVT shift selector connector M78 terminal 7 and ground.

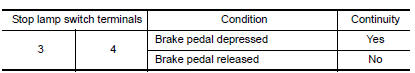

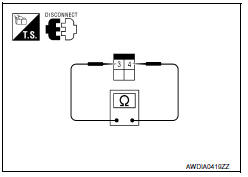

1.CHECK STOP LAMP SWITCH

Check continuity between stop lamp switch terminals.

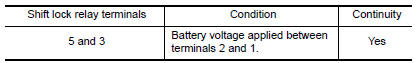

Component Inspection (Shift Lock Relay)

1.CHECK SHIFT LOCK RELAY

-

Apply battery voltage between terminals 2 and 1 of the shift lock relay.

CAUTION: Connect a fuse between the terminals when applying battery voltage.

-

Check continuity between shift lock relay terminals 5 and 3.

Shift position indicator circuit

Shift position indicator circuit

Description

TCM sends position indicator signals to

combination meter via CAN communication line.

The selector lever position is indicated on the

shift position indica ...

ECU diagnosis information

ECU diagnosis information

TCM

Reference Value

VALUES ON THE DIAGNOSIS TOOL

TERMINAL LAYOUT

PHYSICAL VALUES

Fail-safe

The TCM has an electrical fail-safe mode. In this mode

TCM operates even if there is an ...

Other materials:

Diagnosis system (meter)

Diagnosis Description

SELF-DIAGNOSIS MODE

Odo/trip meter and information display segment operation can be

checked in self-diagnosis mode.

Meters/gauges can be checked in self-diagnosis mode.

OPERATION PROCEDURE

Turn the ignition switch OFF.

While pushing the odo/trip meter switch, ...

Difference between predicted and actual distances

The displayed guidelines and their locations on

the ground are for approximate reference only.

Objects on uphill or downhill surfaces or projecting

objects will be actually located at distances

different from those displayed in the monitor relative

to the guidelines (refer to illustrations). ...

Unlocking doors

1. Carry the Intelligent Key.

2. Push the door handle request switch.

3. The door on which the request switch was

pressed will unlock and the hazard warning

lights flash once, the outside buzzer sounds

once, and the front and tail lights will turn on

for 30 seconds.

4. Push the door ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0226