Nissan Maxima Service and Repair Manual: ECU diagnosis information

TCM

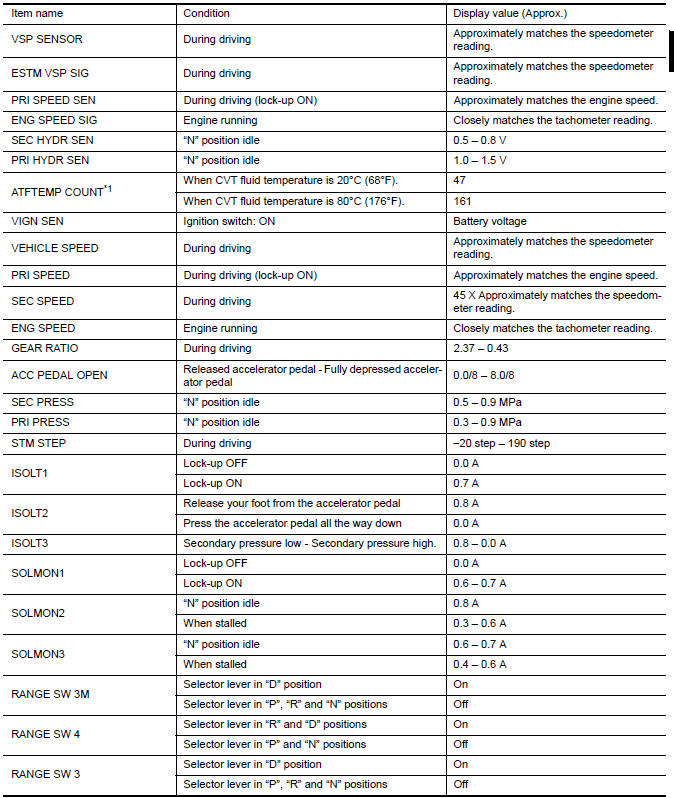

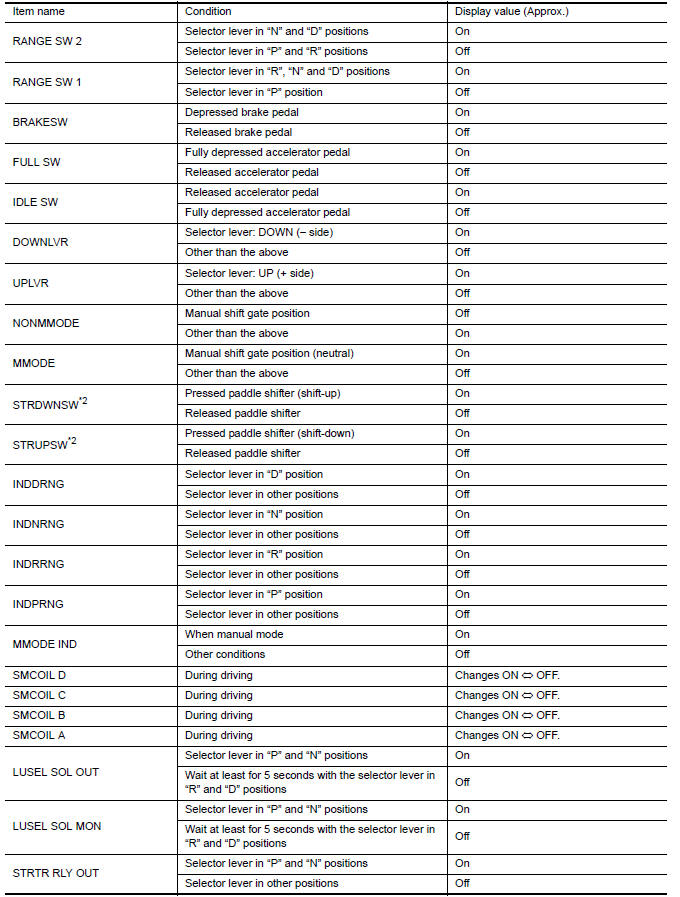

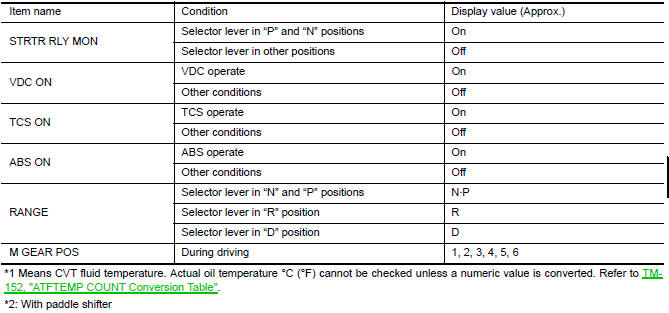

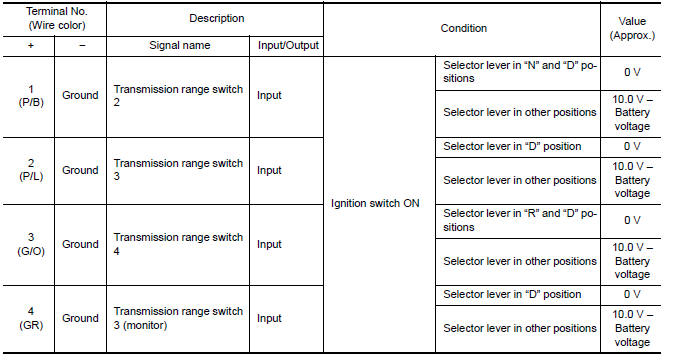

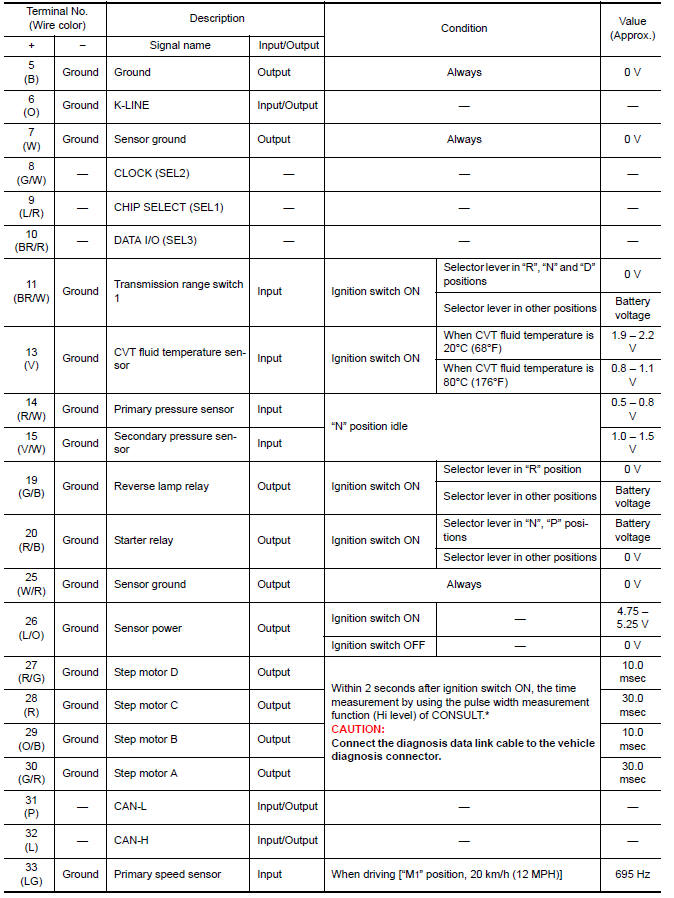

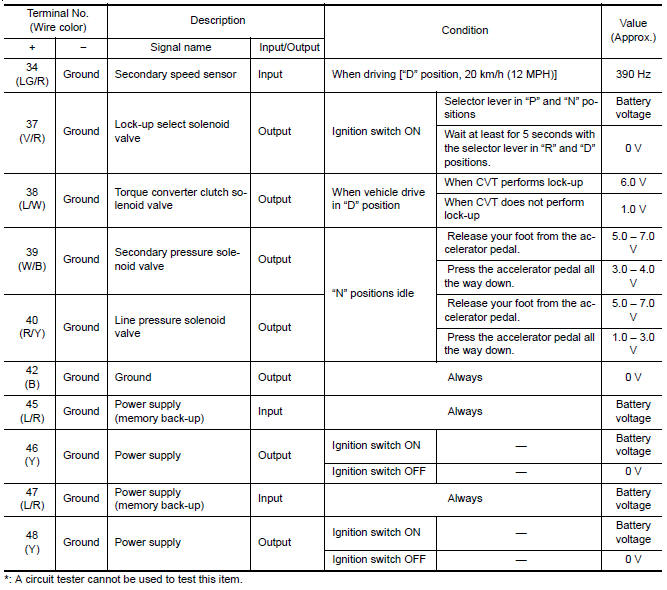

Reference Value

VALUES ON THE DIAGNOSIS TOOL

TERMINAL LAYOUT

PHYSICAL VALUES

Fail-safe

The TCM has an electrical fail-safe mode. In this mode TCM operates even if there is an error in a main electronic control input/output signal circuit.

FAIL-SAFE FUNCTION If any malfunction occurs in a sensor or solenoid valve, this function controls the CVT to make driving possible.

Secondary Speed Sensor The shift pattern is changed in accordance with the throttle position when an unexpected signal is sent from the secondary speed sensor to the TCM. The manual mode and "DS" mode are inhibited, and the transaxle is put in "D".

Primary Speed Sensor The shift pattern is changed in accordance with the throttle position and secondary speed (vehicle speed) when an unexpected signal is sent from the primary speed sensor to the TCM. The manual mode and "DS" mode are inhibited, and the transaxle is put in "D".

Transmission Range Switch If an unexpected signal is sent from the transmission range switch to the TCM, the transaxle is put in "D".

CVT Fluid Temperature Sensor

If an unexpected signal is sent from the CVT fluid temperature sensor to the TCM, the gear ratio in use before receiving the unexpected signal is maintained or the gear ratio is controlled to keep engine speed under 5,000 rpm.

Secondary Pressure Sensor

-

If an unexpected signal is sent from the secondary pressure sensor to the TCM, the secondary pressure feedback control is stopped and the offset value obtained before the non-standard condition occurs is used to control line pressure.

-

If secondary pressure sensor error signal is inputted to the TCM, secondary pressure feedback control stops, but line pressure is controlled normally.

Line Pressure Solenoid Valve

If an unexpected signal is sent from the solenoid valve to the TCM, the line pressure solenoid valve is turned OFF to achieve the maximum fluid pressure.

Secondary Pressure Solenoid Valve

If an unexpected signal is sent from the solenoid valve to the TCM, the secondary pressure solenoid valve is turned OFF to achieve the maximum fluid pressure.

Torque Converter Clutch Solenoid Valve

If an unexpected signal is sent from the solenoid valve to the TCM, the torque converter clutch solenoid valve is turned OFF to cancel the lock-up.

Step Motor

If an unexpected signal is sent from the step motor to the TCM, the step motor coil phases "A" through "D" are all turned OFF to hold the gear ratio used just before the non-standard condition occurred.

Lock-up Select Solenoid Valve

If an unexpected signal is sent from the solenoid valve to the TCM, the lock-up select solenoid valve is turned OFF to cancel the lock-up.

TCM Power Supply (Memory Back-up)

Transaxle assembly is protected by limiting the engine torque when the memory back-up power supply (for controlling) from the battery is not supplied to the TCM. Normal status is restored when turning the ignition switch OFF to ON after the normal power supply.

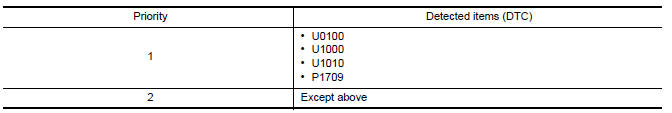

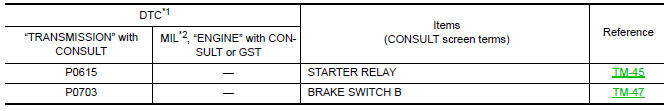

DTC Inspection Priority Chart

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority chart.

NOTE: If DTC "U0100/U1000/U1010/P1709" is indicated with other DTCs, start from a diagnosis for DTC "U0100/U1000/U1010/P1709". Refer to TM-42 (U0100), TM-43 (U1000), TM-44 (U1010), TM-99 (P1709).

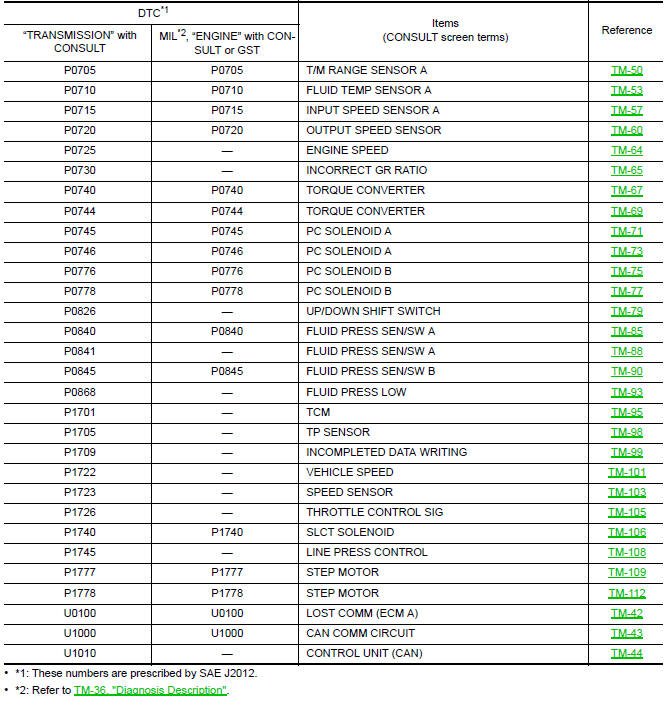

DTC Index

NOTE: If DTC "U0100/U1000/U1010/P1709" is indicated with other DTCs, start from a diagnosis for DTC "U0100/U1000/U1010/P1709". Refer to TM-42 (U0100), TM-43 (U1000), TM-44 (U1010), TM-99 (P1709).

Shift lock system

Shift lock system

Description

The selector lever cannot be shifted from "P" position to

any other position unless the ignition switch is in the

ON position and the brake pedal is depressed.

Component Function Che ...

Wiring diagram

Wiring diagram

CVT CONTROL SYSTEM

Wiring Diagram

...

Other materials:

Parking, license plate and tail lamps are not turned on

Description

The parking, license plate and tail lamps do not turn ON in with any lighting

switch setting.

Diagnosis Procedure

1.COMBINATION SWITCH (LIGHTING AND TURN SIGNAL SWITCH) INSPECTION

Check the combination switch (lighting and turn signal switch).

2.CHECK TAIL LAMP RELAY REQUEST SIGNA ...

Electric ignition system

System Diagram

System Description

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM via the CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and

battery voltage.

SYSTEM DESCRIPTION

Ignition order: 1 - 2 - 3 - 4 - 5 - 6

The ...

Periodic maintenance

FRONT SUSPENSION ASSEMBLY

Inspection and Adjustment

INSPECTION

Make sure the mounting conditions (looseness, backlash) of each component and

component conditions (wear, damage) are normal.

LOWER BALL JOINT END PLAY

Set front wheels in a straight-ahead position. Do not depress

brake peda ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0118