Nissan Maxima Service and Repair Manual: Insufficient heating

Component Function Check

Symptom

- Insufficient heating

- No warm air comes out. (Airflow volume is normal.)

INSPECTION FLOW

1. CONFIRM SYMPTOM BY PERFORMING OPERATION CHECK - TEMPERATURE INCREASE

- Press the AUTO switch.

- Turn temperature control switch (driver side) clockwise until 32C (90F) is displayed.

- Check for hot air at discharge air outlets.

2. CHECK FOR ANY SYMPTOMS

Perform a complete operational check and check for any symptoms.

3. CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

4. CHECK ENGINE COOLING SYSEM

- Check for proper engine coolant level. Refer to CO-10, "System Inspection".

- Check hoses for leaks or kinks.

- Check radiator cap. Refer to CO-10, "System Inspection".

- Check for air in cooling system.

5.CHECK SETTING OF TEMPERATURE SETTING TRIMMER

Using CONSULT, check the setting of "TEMP SET CORRECT" on "WORK SUPPORT" of HVAC.

- Check that the temperature setting trimmer is set to "− direction". NOTE: The control temperature can be set by the temperature setting trimmer.

- Set temperature control dial to "0".

6.CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT

- Using CONSULT, perform "SELF-DIAGNOSIS RESULTS" of HVAC.

- Check if any DTC No. is displayed in the trouble diagnosis results.

NOTE: If DTC is displayed along with DTC U1000 or U1010, first diagnose the DTC U1000 or U1010.

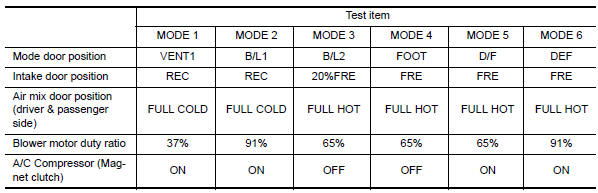

7.CHECK WITH ACTIVE TEST OF CONSULT

- Using CONSULT, perform "HVAC TEST" in "ACTIVE TEST" of HVAC to check each output device. Refer to HAC-129, "CONSULT Function". NOTE: Perform the ACTIVE TEST after starting the engine because the A/C compressor is operating.

- Refer to the table and check the outlet, inlet, airflow temperature, blower motor control signal, magnet clutch operation, and air mix ratio. Visually check each operating condition, by listening for noise, touching air outlets with a hand, etc.

8. CHECK AIR DUCTS

Check for disconnected or leaking air ducts.

9. CHECK HEATER HOSE TEMPERATURES

- Start engine and warm it up to normal operating temperature.

- Touch both the inlet and outlet heater hoses. The inlet hose should be hot and the outlet hose should be warm.

10. CHECK ENGINE COOLANT SYSTEM

Check thermostat operation.

11. CHECK HEATER HOSES

Check heater hoses for proper installation.

12. CHECK HEATER HOSE TEMPERATURES

- Start engine and warm up to normal operating temperature.

- Touch both the inlet and outlet heater hoses. The inlet hose should be hot and the outlet hose should be warm.

Insufficient cooling

Insufficient cooling

Component Function Check

Symptom

Insufficient cooling

No cool air comes out. (Airflow volume is normal.)

INSPECTION FLOW

1. CONFIRM SYMPTOM BY PERFORMING OPERATION CHECK - TEMPERATURE DECRE ...

Noise

Noise

Component Function Check

Symptom

Noise

Noise is heard when the A/C system operates.

INSPECTION FLOW

...

Other materials:

Unit disassembly and assembly

DOOR MIRROR

Exploded View

Door mirror glass

Actuator assembly

Door mirror assembly

Disassembly

Turn the door mirror glass surface upward.

Pull from the bottom to disengage lower clips

Lift to disengage the upper mirror hooks (A).

Disconnect the harness connect ...

Glove box

Open the glove box by pulling the handle. Use the

master key when locking or unlocking the glove

box.

There is a trunk cancel switch in the glove box.

For additional information, refer to "Cancel

switch" in the "Pre-driving checks and adjustments"

section of this manual.

WARNING

Keep g ...

Rear regulator

Rear Door Glass Regulator

REMOVAL

Remove the rear door finisher. Refer to INT-21, "Removal and

Installation".

Position aside the vapor barrier.

Temporarily reconnect the power window switch and raise/lower

the door window until the glass bolts can be seen.

Remove the glass bolt ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0063