Nissan Maxima Service and Repair Manual: Front seat

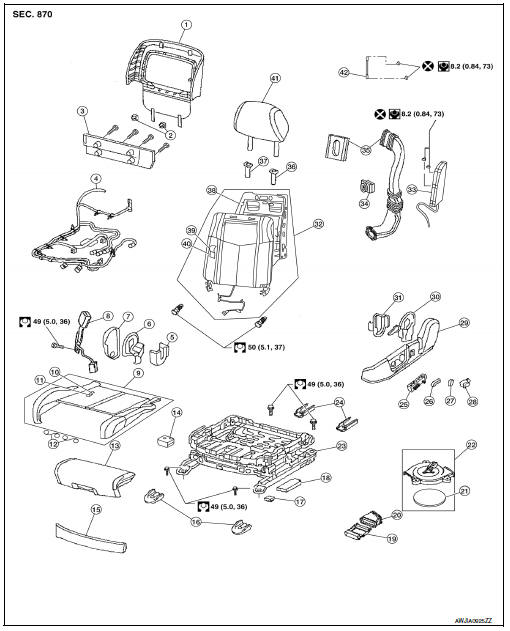

Exploded View

DRIVER

Driver Seat - With Climate Controlled Seats

- Seatback board

- Seatback board clip

- Seat cushion lower rear finisher

- Seat harness

- Seat cushion inner finisher inside (RH)

- Recline mechanism inner cover

- Seat cushion outer finisher (RH)

- Seat belt buckle

- Seat cushion assembly

- Seat cushion trim

- Seat cushion pad

- Thigh extension tether

- Thigh extension assembly

- Climate controlled seat control unit

- Seat cushion front finisher

- Front slide cover

- Clip

- Power seat control unit

- Seat cushion thermal electric device (TED)

- Lower seat duct

- Climate controlled seat blower filter

- Climate controlled seat blower motor assembly

- Seat frame assembly

- Rear slide cover

- Power seat switch

- Seat slide and lifter switch knob

- Seat recline knob

- Lumbar support switch

- Seat cushion outer finisher (LH)

- Recline device outer cover

- Seat cushion inner finisher inside (LH)

- Seatback assembly

- Side air bag module

- Seatback thermal electric device (TED)

- Upper seat duct

- Headrest holder (locked)

- Headrest holder (free)

- Seatback frame

- Seatback trim

- Seatback pad

- Headrest

- Chute rod

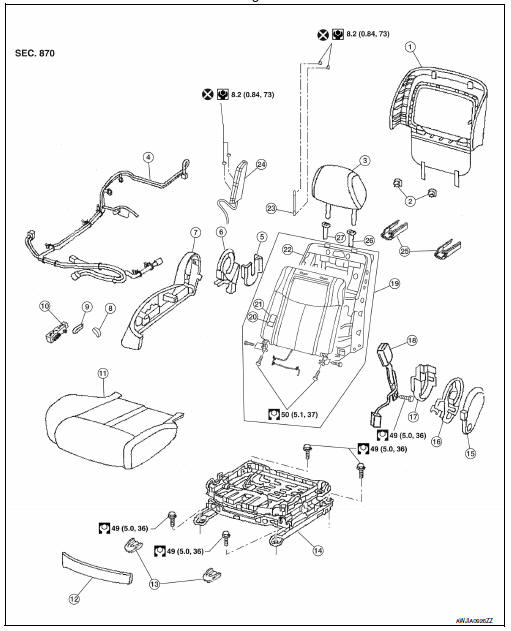

PASSENGER

Passenger Seat

- Seatback board

- Seatback board clips

- Headrest

- Seat harness

- Seat cushion inner finisher inside (RH)

- Recline device inner cover

- Seat cushion outer finisher (RH)

- Seat recline knob

- Seat slide and lifter switch knob

- Power seat switch

- Seat cushion assembly

- Seat cushion front finisher

- Front slide cover

- Seat frame assembly

- Seat cushion outer finisher (LH)

- Recline mechanism inner cover

- Seat cushion inner finisher inside (LH)

- Seat belt buckle

- Seatback assembly

- Seatback pad

- Seatback trim

- Seatback frame

- Chute rod

- Side air bag module

- Rear slide cover

- Headrest holder (locked)

- Headrest holder (free)

Removal and Installation

REMOVAL

WARNING:

Do not leave any objects (screwdrivers, tools, etc.) on the seat during seat repair. It can lead to personal injury if the side air bag module should accidentally deploy.

CAUTION:

- When removing or installing the seat trim, handle it carefully to keep dirt out and to avoid damage.

- When checking the power seat circuit for continuity using a circuit tester, do not confuse its connector with the side air bag module connector. Such an error may cause the air bag module to deploy.

- Do not drop, tilt, or bump the side air bag module while installing the seat. Always handle it with care.

- After the front side air bag module inflates, the front seatback assembly must be replaced.

- When removing and installing the seat, use shop cloths to protect components from damage.

- Before removing the front seat, turn the ignition switch OFF, disconnect both battery terminals and wait at least three minutes.

- Slide the seat to the full forward position.

- Remove the rear slide covers. a. Release the pawls (A).

b. Remove the rear slide covers.

3. Remove the rear mount bolts.

4. Slide the seat to the full rearward position.

5. Remove the front slide covers.

6. Remove the front mount bolts.

7. Disconnect the negative and positive battery terminals and wait at least three minutes. Refer to PG-67, "Removal and Installation (Battery)".

8. Disconnect the harness connector under the seat and remove harness clips.

9. Remove seat from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Make sure that the seat harness or the floor trim is not damaged during installation.

NOTE:

- When installing the LH front seat, tighten the bolts in the order shown.

- When installing the RH front seat, tighten the bolts in the order shown.

Rear seat

Rear seat

Exploded View - Fixed Seatback

Headrest

Headrest holder (free)

Headrest holder (locked)

Bumper

Seatback assembly

Seatback trim

Seatback pad

Seat cushion trim

Seat cushion p ...

Other materials:

Removal and installation

POWER SOCKET

Removal and Installation

POWER SOCKET

NOTE: If the tool does not fit because of

the location of the power socket, further disassembly may be required. Refer

to IP-14, "Removal and Installation".

Removal

Remove the fuse for the power socket.

Insert one end of the Tool (A) i ...

Battery

Keep the battery surface clean and dry.

Clean the battery with a solution of baking

soda and water.

Make certain the terminal connections are

clean and securely tightened.

If the vehicle is not to be used for 30 days or

longer, disconnect the negative (-) battery

terminal cable to ...

AMP on signal circuit

Description

When the audio system is turned on, a voltage signal is supplied from the AV

control unit to the BOSE speaker

amp. When this signal is received, the BOSE speaker amp. will turn on.

Diagnosis Procedure

1.CHECK AMP ON SIGNAL (BOSE SPEAKER AMP)

Turn audio system ON.

Check v ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0079