Nissan Maxima Service and Repair Manual: Rear seat

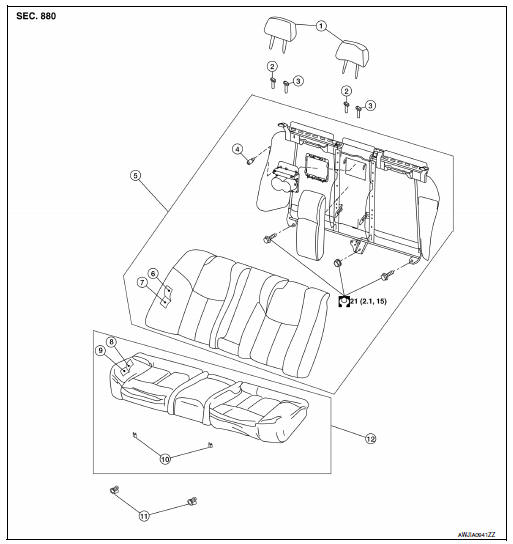

Exploded View - Fixed Seatback

- Headrest

- Headrest holder (free)

- Headrest holder (locked)

- Bumper

- Seatback assembly

- Seatback trim

- Seatback pad

- Seat cushion trim

- Seat cushion pad

- Seat cushion wire cover

- Seat cushion lock

- Seat cushion assembly

Removal and Installation

CAUTION:

When removing and installing, use shop cloths to protect parts from damage.

SEAT CUSHION ASSEMBLY

Removal

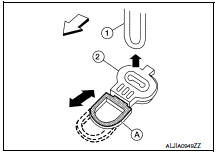

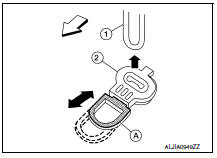

- Locate the seat cushion lock (2) at the front bottom of the seat

cushion assembly (one for each side). Pull the release lever (A)

forward and lift the seat cushion assembly upward to release the

seat cushion wire (1) from the seat cushion lock (2).

: Front

: Front - Then pull the seat cushion assembly forward to remove.

Installation

Installation is in the reverse order of removal.

SEATBACK

Removal

- Remove the seat cushion assembly.

- Remove the headrests (LH/RH).

- Remove the seatback assembly bolts and nut.

4. Lift the seatback to disengage seat hook wires from the hangers.

Installation

Installation is in the reverse order of removal.

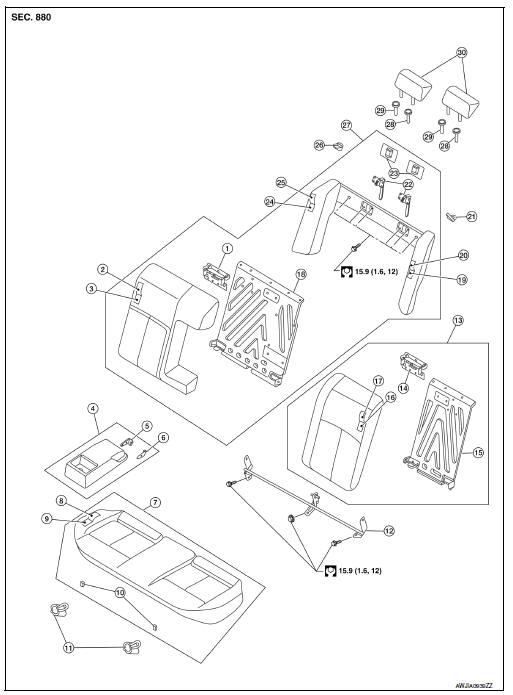

Exploded View - 60:40 Split Seatback

- Seatback latch striker (RH)

- Seatback trim (RH)

- Seatback pad (RH)

- Armrest assembly

- Inner armrest bracket (RH)

- Inner armrest bracket (LH)

- Seat cushion assembly

- Seat cushion trim

- Seat cushion pad

- Seat cushion wire cover

- Seat cushion lock

- Seatback hinge assembly

- Seatback assembly (LH)

- Seatback latch striker (LH)

- Seatback frame (LH)

- Seatback pad (LH)

- Seatback trim (LH)

- Seatback frame (RH)

- Side bolster pad (LH)

- Side bolster trim (LH)

- Seat belt guide (LH)

- Seatback latch assembly

- Seatback latch cover

- Side bolster pad (RH)

- Side bolster trim (RH)

- Seat belt guide (RH)

- Seatback assembly (RH)

- Headrest holder (locked)

- Headrest holder (free)

- Headrest

Removal and Installation

CAUTION:

When removing and installing, use shop cloths to protect parts from damage.

SEAT CUSHION ASSEMBLY

Removal

- Locate the seat cushion lock (2) at the front bottom of the seat

cushion assembly (one for each side). Pull the release lever (A)

forward and lift the seat cushion assembly upward to release the

seat cushion wire (1) from the seat cushion lock (2).

: Front

: Front - Then pull the seat cushion assembly forward to remove.

Installation

Installation is in the reverse order of removal.

SEATBACK

Removal

- Lock seatback (LH/RH) in upright position.

- Remove the seatback hinge assembly bolts and nut.

- Fold seatback (LH/RH) forward.

4. Remove seatback latch covers (A).

5. Remove the halo upper frame assembly bolts (B).

6. Remove the seatback assembly.

Installation

Installation is in the reverse order of removal.

Front seat

Front seat

Exploded View

DRIVER

Driver Seat - With Climate Controlled Seats

Seatback board

Seatback board clip

Seat cushion lower rear finisher

Seat harness

Seat cushion inner finisher inside ...

Climate controlled seat blower filter

Climate controlled seat blower filter

Removal and Installation

REMOVAL

CAUTION:

When removing and installing, use shop cloths to protect parts

from damage.

Remove front seat. Refer to SE-68, "Removal and Installation".

Turn blo ...

Other materials:

Outside mirrors

The outside mirror remote control will operate

only when the ignition switch is in the ACC or ON

position.

Move the small switch 1 to select the right or left

mirror. Adjust each mirror to the desired position

using the large switch 2 .

WARNING

Objects viewed in the outside mirror on ...

Id registration cannot be completed

ID Registration Cannot Be Completed

NOTE: The Signal Tech II Tool (J-50190) can be used

to perform the following functions. Refer to the Signal Tech II User Guide

for additional information.

Activate and display TPMS transmitter IDs

Display tire pressure reported by the TPMS t ...

Rear window defogger power supply and ground circuit

Description

Heats the heating wire with the power supply from the rear window defogger

relay to prevent the rear window

from fogging up.

Component Function Check

1. CHECK REAR WINDOW DEFOGGER

Check that the heating wire of rear window defogger is heated when turning

the rear window defogge ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0069