Nissan Maxima Service and Repair Manual: Power supply and ground circuit

BCM

BCM : Diagnosis Procedure

Regarding Wiring Diagram information, refer to BCS-67, "Wiring Diagram".

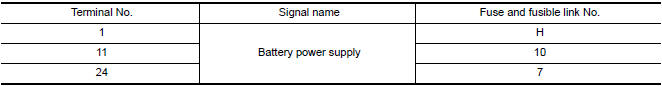

1. CHECK FUSE AND FUSIBLE LINK

Check if the following BCM fuses or fusible link are blown.

Is the fuse or fusible link blown?

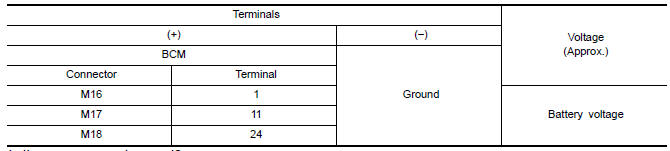

2. CHECK POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect BCM.

- Check voltage between BCM harness connector and ground.

Is the measurement norma

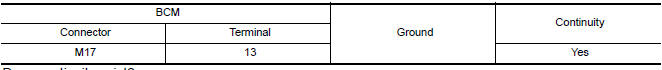

3. CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

DRIVER SEAT CONTROL UNIT

DRIVER SEAT CONTROL UNIT : Diagnosis Procedure

NOTE: Do not disconnect the battery negative terminal and the driver seat control unit connector until DTC is confirmed with CONSULT.

Regarding Wiring Diagram information, refer to ADP-150, "Wiring Diagram".

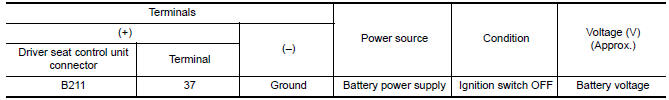

1. CHECK POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect driver seat control unit.

- Check voltage between driver seat control unit harness connector and ground.

Is the inspection result normal?

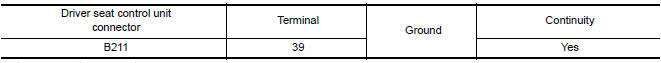

2. CHECK GROUND CIRCUIT

Check continuity between the driver seat control unit harness connector and ground.

Is the inspection result normal?

DRIVER SEAT CONTROL UNIT : Special Repair Requirement

1.PERFORM ADDITIONAL SERVICE

Perform additional service when removing battery negative terminal.

AUTOMATIC DRIVE POSITIONER CONTROL UNIT

AUTOMATIC DRIVE POSITIONER CONTROL UNIT : Diagnosis Procedure

NOTE: Do not disconnect the battery negative terminal and the driver seat control unit connector until DTC is confirmed with CONSULT.

Regarding Wiring Diagram information, refer to ADP-150, "Wiring Diagram".

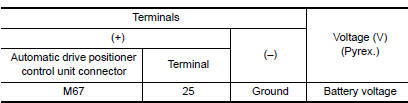

1. CHECK POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect automatic drive positioner control unit.

- Check voltage between automatic drive positioner control unit harness connector and ground.

Is the inspection result normal?

2. CHECK GROUND CIRCUIT

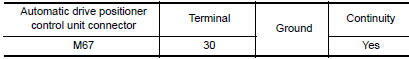

Check continuity between the automatic drive positioner control unit harness connector and ground.

Is the inspection result normal?

AUTOMATIC DRIVE POSITIONER CONTROL UNIT : Special Repair Requirement

1.PERFORM ADDITIONAL SERVICE

Perform additional service when removing battery negative terminal.

B2128 UART communication line

B2128 UART communication line

Description

Driver seat control unit performs UART communication with the automatic drive

positioner control unit using 1 communication line. Driver seat control unit

receives the operation signa ...

Sliding switch

Sliding switch

Description

Sliding switch is equipped to the power seat switch LH on the seat frame. The

operation signal is input to the driver seat control unit when the sliding

switch is operated.

Component ...

Other materials:

Front seat

Exploded View

DRIVER

Driver Seat - Without Climate Controlled Seats

Headrest

Headrest holder (free)

Headrest holder (locked)

Seatback board

Seatback board clip

Seat cushion inner finisher inside (RH)

Recline mechanism inner cover

Seat cushion outer finisher (RH)

Seat be ...

B1065 - B1068, B1070 - B1073 passenger airbag module

Description

DTC B1065 - B1068, B1070 - B1073 PASSENGER AIR BAG MODULE

The passenger air bag module is dual stage and wired to the air bag diagnosis

sensor unit. The air bag diagnosissensor unit will monitor for opens and

shorts in detected lines to the passenger air bag module.

PART LOCATION

...

Three-way catalyst

The three-way catalyst is an emission control

device installed in the exhaust system. Exhaust

gases in the three-way catalyst are burned at

high temperatures to help reduce pollutants.

WARNING

The exhaust gas and the exhaust system

are very hot. Keep people, animals

or flammable material ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0073