Nissan Maxima Service and Repair Manual: Hood

HOOD ASSEMBLY

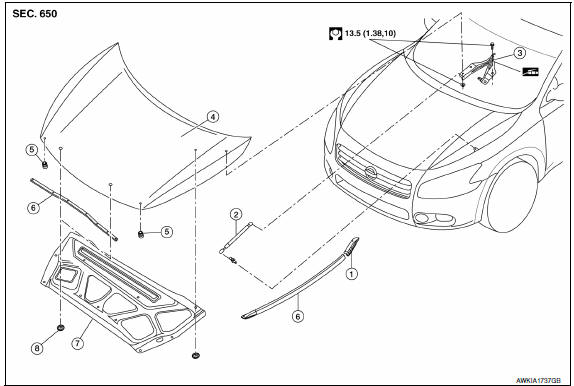

HOOD ASSEMBLY : Exploded View

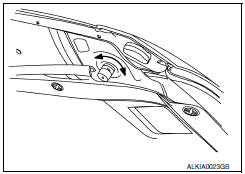

- Hood hinge cover (LH)

- Hood stay (LH)

- Hood hinge (LH)

- Hood assembly

- Hood bumper rubber

- Seal

- Hood insulator

- Hood insulator clips

HOOD ASSEMBLY : Removal and Installation

CAUTION:

- Use two people when removing or installing hood assembly due to its heavy weight.

- Use protective tape or shop cloths to protect surrounding components from damage during removal and installation of hood assembly.

REMOVAL

- Support the hood assembly using a suitable tool.

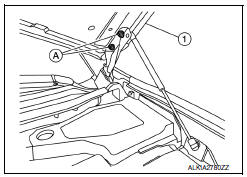

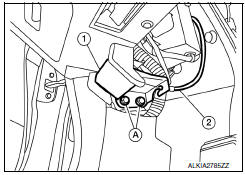

- Remove hood hinge to hood nuts (A) and then remove the hood assembly (1).

WARNING: Bodily injury may occur if hood assembly is not supported properly when removing hood assembly.

INSTALLATION Installation is in the reverse order of removal.

CAUTION:

- After installation, perform the hood assembly adjustment procedure.

- When replacing hood stay(s)

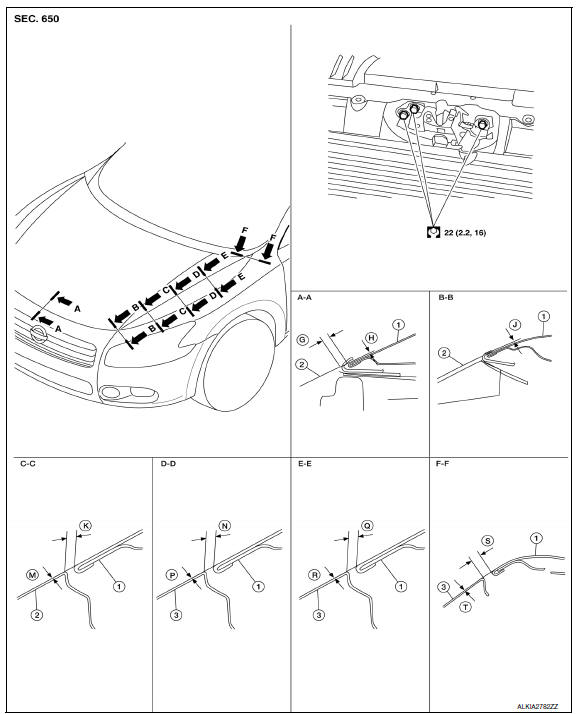

HOOD ASSEMBLY : Adjustment

- Hood assembly

- Front fascia

- Front fender

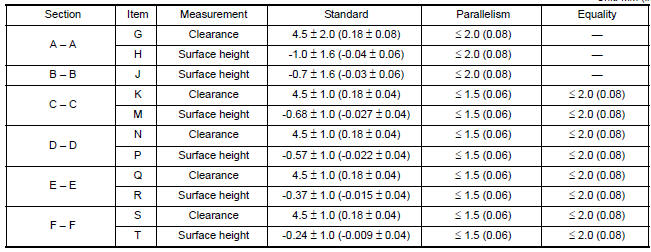

FRONT END HEIGHT ADJUSTMENT AND LATERAL/LONGITUDUNAL CLEARANCE ADJUSTMENT

Check the clearance and the surface height between hood and each part by visual inspection and tactile feel.

If the clearance and the surface height are out of specification, adjust them according to the adjustment procedures.

FRONT END HEIGHT ADJUSTMENT

- Remove the core support cover clips, then remove the core support cover.

- Remove the hood lock. Refer to DLK-205, "HOOD LOCK CONTROL : Removal and Installation".

- Adjust the surface level difference of the hood, fender and front fascia by rotating the hood bumpers until the hood becomes 1 to 1. 5 mm (0. 04 to 0. 06 in) lower than the fender.

- Install and align the hood lock center with the center of the hood striker. Engage the lock with the striker and check for looseness. \

- Adjust (A) and (B) shown in the figure to the specified value with hood's own weight by dropping it from approx. 200 mm (7. 9 in) height or by pressing the hood closed lightly approximately 29 N (3. 0 kg, 6. 5 lb).

- Hood striker

- Primary latch

- Secondary latch

- Secondary striker

- 20 mm (0. 8 in)

- 6. 8 mm (0. 27 in)

- After adjustment tighten the hood lock bolts to the specified torque.

LATERAL/LONGITUDUNAL CLEARANCE ADJUSTMENT

- Loosen the hood hinge bolts.

NOTE:

The anticorrosive agent applied between the hoodledge and the hood hinges

also acts as an adhesive.

This seal must be broken before the hinges will move.

- Move the hood so that the clearance measurements are within specifications provided.

- Tighten the hood hinge bolts to the specified torque. NOTE: After installation apply touch-up paint onto the hinge bolts and around the base of the hinge.

- If the clearance measurements between the hood and fender cannot be corrected by adjusting the hood, the fender must be adjusted.

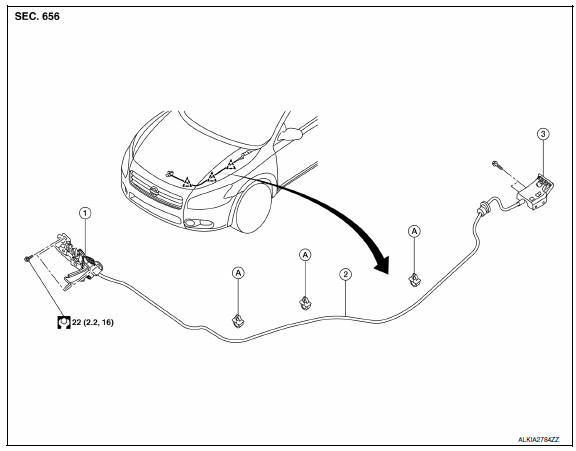

HOOD LOCK CONTROL

HOOD LOCK CONTROL : Exploded View

- Hood lock assembly

- Hood lock release cable

- Hood lock release handle

- Hood lock release cable clip

Clip

Clip

HOOD LOCK CONTROL : Removal and Installation

REMOVAL

- Remove the core support cover clips, then remove the core support cover.

- Remove the fender protector (LH).

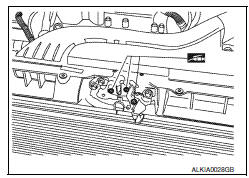

- Remove the hood lock assembly bolts (

).

).

- Disconnect the hood lock release cable from the hood lock, and unclip it from the hoodledge.

- Remove the bolts (A) and separate the hood lock release handle (1) from the hood lock release cable (2).

- Remove the grommet from the upper dash, and pull the hood lock release cable into the passenger compartment.

CAUTION: While pulling, be careful not to damage (peel) the outside of the hood lock release cable.

INSTALLATION

- Pull the hood lock release cable through the upper dash into the

engine compartment.

CAUTION: Be careful not to bend the hood lock release cable too much, keep the radius 100 mm (3. 9 in) or more. - Check that the hood lock release cable is not offset from the center of the grommet and seat the grommet into the upper dash hole.

- Apply the sealant around the grommet at * mark.

- Position the hood lock release cable and clip it into place.

- Connect the hood lock release cable to the hood lock assembly

- Install the bolts to hood lock release handle.

Bolts 10 N?m (1. 0 kg-m, 7ft-lb)

- Loosely install the hood lock assembly.

- Perform hood fitting adjustment. Refer to DLK-203, "HOOD ASSEMBLY : Adjustment".

- Perform the hood lock control inspection. Refer to DLK-207, "HOOD LOCK CONTROL : Inspection".

HOOD LOCK CONTROL : Inspection

INSPECTION

CAUTION: If the hood lock cable is bent or deformed, replace it.

- Check that the secondary latch is properly engaged with the secondary striker with hood's own weight.

- Hood striker

- Primary latch

- Secondary latch

- Secondary striker

- 20 mm (0. 8 in)

- 6. 8 mm (0. 27 in)

- While operating the hood lock release handle, carefully check that the front end of the hood is raised by approx. 20 mm (0. 8 in). Also check that the hood lock release handle returns to the original position.

- Check that the hood lock release handle operating force is 49 N (5. 0 kg, 11. 0 lb) or below.

- Install so the static closing force of the hood assembly is 315 - 490 N*m (32. 1- 50. 0 kg-m, 70. 8 - 110. 2 ftlb).

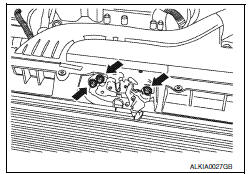

- Check the hood lock assembly lubrication condition. If necessary,

apply a suitable multi-purpose grease as shown.

: Grease

: Grease

HOOD STAY

HOOD STAY : Disposal

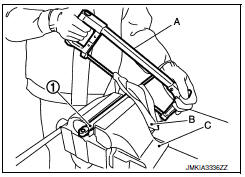

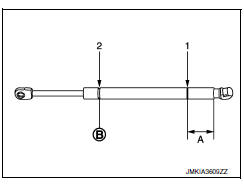

- Fix hood stay (1) using a vise (C).

- Using hacksaw (A) slowly make 2 holes in the hood stay (1), in numerical order as shown.

CAUTION:

- When cutting a hole on hood stay, always cover hacksaw with a shop cloth (B) to avoid scattering metal fragments or oil.

- Wear eye protection (safety glasses).

- Wear gloves.

A: 20 mm (0. 8 in)

B: Cut at the groove.

Radiator core support

Radiator core support

Exploded View

Radiator core support

Bolts

Removal and Installation

REMOVAL

Remove front bumper. Refer to EXT-16, "Removal and Installation".

Remove front combinat ...

Other materials:

Engine compartment check locations

VQ35DE engine

1. Engine coolant reservoir

2. Drive belt location

3. Engine oil filler cap

4. Brake fluid reservoir

5. Air cleaner

6. Fuse block

7. Fuse block/Fusible links

8. Fusible links

9. Battery

10. Engine oil dipstick

11. Radiator cap

12. Power steering fluid reservoir

13. Win ...

System description

EPS SYSTEM

System Diagram

CONTROL DIAGRAM

System Description

The EPS system controls the power steering solenoid valvethrough the

power steering control unit.

The valve driving voltage to control the power steering solenoid

valve varies according to the vehicle speed.

OPERATION ...

DTC/circuit diagnosis

POWER SUPPLY AND GROUND CIRCUIT

COMBINATION METER

COMBINATION METER : Diagnosis Procedure

Regarding Wiring Diagram information, refer to MWI-87, "Wiring Diagram".

1.CHECK FUSES

Check for blown combination meter fuses.

2.POWER SUPPLY CIRCUIT CHECK

Disconnect combination meter connector.

...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0071