Nissan Maxima Service and Repair Manual: Roof finisher

Removal and Installation

REMOVAL

- Open the glass lid.

- Apply protective tape around the roof side finisher to protect the surface from damage.

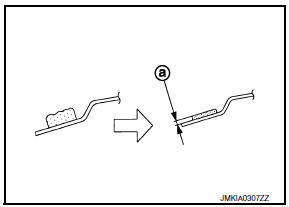

- Cut adhesive.

- Pass piano wire through the adhesive with a wire pierce.

- Tie piano wire on both ends to assist in wire grip.

- Pull piano wire with sawing motion to cut through adhesive, working along the length of the panel.

- Remove the roof side finisher.

INSTALLATION

WARNING:

- Keep heat and open flames away as primers and adhesive are flammable.

- The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Never let them contact the skin or eyes.

- Use in an open, well ventilated location. Never breathe the

vapors. They may be harmful if inhaled.

Move immediately to an area with fresh air if affected by vapor inhalation.

NOTE:

- Use a genuine Nissan Urethane Adhesive Kit (if available) or an equivalent and follow the instructions furnished with it.

- Inform the customer that the vehicle should remain stationary until the urethane adhesive has completely cured (approximately 24 hours). Curing time varies with temperature and humidity.

- Using a knife or spatula, trim the adhesive (sealant) remaining on body down to approximately 2 mm thick (a) so that the contour becomes smooth.

CAUTION: If bonded area on body is scratched, be sure to repair it with a 2-component urethane. Do not use lacquer.

- When installing new roof side finisher, position the roof side finisher dry (no adhesive) first onto the vehicle and paint mating marks on the body and roof side finisher, then remove it again.

- Thoroughly clean bonding area on the roof side finisher and the body with isopropyl alcohol or equivalent.

- Apply primer to the body and the roof side trim (lower) surfaces.

- Apply adhesive to the contact areas of the body within the time specified in the instructions for the adhesive.

- Open adhesive by cutting off the nozzle tip and set it in a sealant gun.

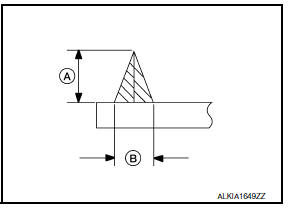

- Form a continuous bead of adhesive resembling the measurements in applied thickness (A), and in applied width (B) on the body panel.

Adhesive applied thickness (A) : 13 +- 1 mm (0.51 +- 0.039 in)

Adhesive

applied width (B) : 8 +- 1 mm (0.31 +- 0.039 in)

- Position the roof side finisher, align the paint marks, then lower it into position.

- Press down lightly by hand to evenly expand the adhesive contact with the roof side finisher.

- Using a suitable tool, remove any adhesive overflow.

- Remove the protective tape.

Sunroof unit assembly

Sunroof unit assembly

Inspection and Adjustment

INSPECTION

Wind Deflector

Open glass lid assembly fully.

Visually check for proper installation, damaged/deteriorated

components, or foreign objects within mec ...

Front sunroof glass

Front sunroof glass

Removal and Installation

REMOVAL

Remove the wind deflector. Refer to RF-168, "Removal and

Installation".

Tape down the glass lid weatherstrip along the from sunroof glass

with protective ...

Other materials:

Parking, license plate and tail lamps

System Diagram

System Description

BCM (Body Control Module) controls parking, license plate and tail lamps

operation.

IPDM E/R (Intelligent Power Distribution Module Engine Room) operates

parking, license plate and tail lamps according to CAN communication

signals from BCM.

Comp ...

Air fresheners

Most air fresheners use a solvent that could affect

the vehicle interior. If you use an air freshener,

take the following precautions:

Hanging-type air fresheners can cause permanent

discoloration when they contact vehicle

interior surfaces. Place the air freshener

in a location that all ...

Diagnosis system (BCM)

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITE

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BC

SYSTEM APPLICATION

BCM can perform the following functions.

INT LAMP

INT LAMP : CONSULT Function (BCM - INT LAMP)

DATA MONITOR

ACTIVE TE ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0081