Nissan Maxima Service and Repair Manual: Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

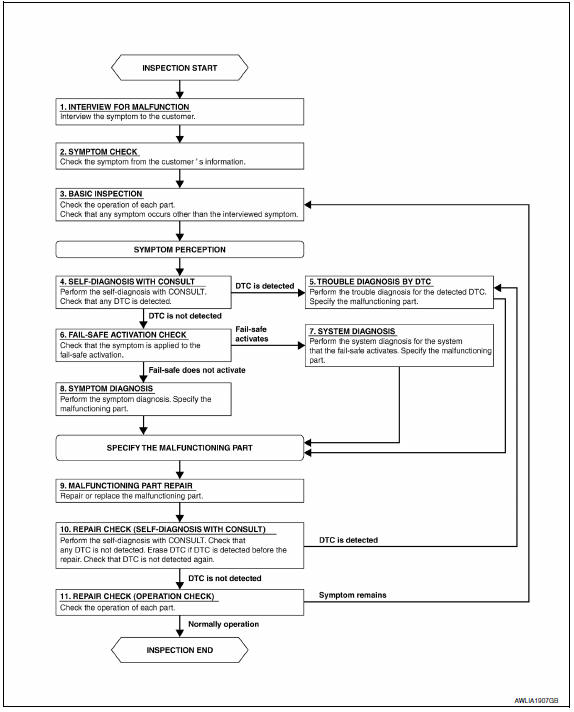

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Find out what the customer's concerns are.

2.SYMPTOM CHECK

Verify the symptom from the customer's information.

3.BASIC INSPECTION

Check the operation of each part. Check if any concerns occur other than those mentioned in the customer interview.

4.SELF-DIAGNOSIS WITH CONSULT

Perform the self diagnosis with CONSULT. Check if any DTC is detected.

5.TROUBLE DIAGNOSIS BY DTC

Perform the trouble diagnosis for the detected DTC. Specify the malfunctioning part.

6.FAIL-SAFE ACTIVATION CHECK

Determine if the customer's concern is related to fail-safe activation.

7.SYSTEM DIAGNOSIS

Perform the system diagnosis for the system in which the fail-safe activates. Specify the malfunctioning part.

8.SYMPTOM DIAGNOSIS

Perform the symptom diagnosis. Specify the malfunctioning part.

9.MALFUNCTION PART REPAIR

Repair or replace the malfunctioning part.

10.REPAIR CHECK (SELF-DIAGNOSIS WITH CONSULT)

Perform the self diagnosis with CONSULT. Verify that no DTCs are detected. Erase all DTCs which were detected prior to the repair. Perform the self diagnosis with CONSULT again. Verify that DTC is not detected again.

11.REPAIR CHECK (OPERATION CHECK)

Check the operation of each part.

Service data and specifications (SDS)

Service data and specifications (SDS)

Bulb Specifications

*: Always check with the Parts Department for the latest parts information. ...

Other materials:

Removal and installation

POWER SOCKET

Removal and Installation

POWER SOCKET

NOTE: If the tool does not fit because of

the location of the power socket, further disassembly may be required. Refer

to IP-14, "Removal and Installation".

Removal

Remove the fuse for the power socket.

Insert one end of the Tool (A) i ...

Tilt motor

Description

The tilt motor is installed to the steering column assembly.

The tilt motor is activated with the automatic drive positioner control

unit.

The steering column is tilted upward/downward by changing the rotation

direction of tilt motor.

Component Function Check

1. CHECK F ...

Intelligent key

Description

The following functions are available when having and carrying the

Intelligent Key.

Door lock/unlock

Trunk open

Remote control entry function and panic alarm function are available when

operating the remote buttons.

Component Function Check

NOTE:

The Signal Tech II To ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0092