Nissan Maxima Service and Repair Manual: P0461 fuel level sensor

Description

The fuel level sensor is mounted in the fuel level sensor unit.

The sensor detects a fuel level in the fuel tank and transmits a signal to the combination meter. The combination meter sends the fuel level sensor signal to the ECM via the CAN communication line.

It consists of two parts, one is mechanical float and the other is variable resistor. Fuel level sensor output voltage changes depending on the movement of the fuel mechanical float.

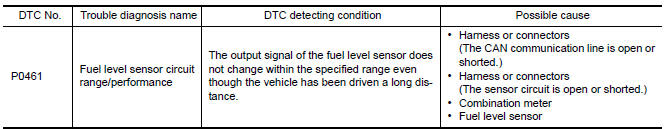

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC P0461 is displayed with DTC UXXXX, first perform the

trouble diagnosis for DTC UXXXX.

Refer to EC-161, "DTC Logic".

- If DTC P0461 is displayed with DTC P0607, first perform the trouble diagnosis for DTC P0607. Refer to EC-393, "DTC Logic".

Driving long distances naturally affect fuel gauge level.

This diagnosis detects the fuel gauge malfunction of the gauge not moving even after a long distance has been driven.

DTC CONFIRMATION PROCEDURE

1.PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to EC-374, "Component Function Check".

Use component function check to check the overall function of the fuel level sensor. During this check, a 1st trip DTC might not be confirmed.

Component Function Check

1.PRECONDITIONING

WARNING: When performing the following procedure, always observe the handling of the fuel. Refer to FL-6, "Removal and Installation". TESTING CONDITION: Before starting component function check, preparation of draining fuel and refilling fuel is required.

2.PERFORM COMPONENT FUNCTION CHECK

With CONSULT

NOTE: Start from step 10, if it is possible to confirm that the fuel cannot be drained by 30 (7-7/8 US gal, 6-5/ 8 Imp gal) in advance.

- Prepare a fuel container and a spare hose.

- Release fuel pressure from fuel line, refer to EC-594, "Inspection".

- Remove the fuel feed hose on the fuel level sensor unit. Refer to FL-6, "Removal and Installation".

- Connect a spare fuel hose where the fuel feed hose was removed.

- Turn ignition switch OFF and wait at least 10 seconds then turn ON.

- Select "FUEL LEVEL SE" in "DATA MONITOR" mode with CONSULT.

- Check "FUEL LEVEL SE" output voltage and note it.

- Select "FUEL PUMP RELAY" in "ACTIVE TEST" mode with CONSULT.

- Touch "ON" and drain fuel approximately 30

(7-7/8 US gal, 6-5/8 Imp gal)

and stop it.

(7-7/8 US gal, 6-5/8 Imp gal)

and stop it. - Check "FUEL LEVEL SE" output voltage and note it.

- Fill fuel into the fuel tank for 30

(7-7/8 US gal, 6-5/8 Imp

gal).

(7-7/8 US gal, 6-5/8 Imp

gal). - Check "FUEL LEVEL SE" output voltage and note it.

- Confirm whether the voltage changes more than 0.03 V during step 7 to 10 and 10 to 12.

3.PERFORM COMPONENT FUNCTION CHECK

Without CONSULT

NOTE: Start from step 8, if it is possible to confirm that the fuel cannot be drained by 30 (7-7/8 US gal, 6-5/8 Imp gal) in advance.

- Prepare a fuel container and a spare hose.

- Release fuel pressure from fuel line. Refer to EC-594, "Inspection".

- Remove the fuel feed hose on the fuel level sensor unit. Refer to FL-6, "Removal and Installation".

- Connect a spare fuel hose where the fuel feed hose was removed.

- Turn ignition switch ON.

- Drain fuel by 30

(7-7/8 US gal, 6-5/8 Imp gal) from the fuel tank using proper equipment.

(7-7/8 US gal, 6-5/8 Imp gal) from the fuel tank using proper equipment. - Confirm that the fuel gauge indication varies.

- Fill fuel into the fuel tank for 30

(7-7/8 US gal, 6-5/8 Imp

gal).

(7-7/8 US gal, 6-5/8 Imp

gal). - Confirm that the fuel gauge indication varies.

Diagnosis Procedure

1.CHECK COMBINATION METER FUNCTION

2.CHECK INTERMITTENT INCIDENT

P0460 fuel level sensor

P0460 fuel level sensor

Description

The fuel level sensor is mounted in the fuel level sensor unit.

The sensor detects a fuel level in the fuel tank and transmits a signal to the

combination meter. The combination

me ...

P0462, P0463 fuel level sensor

P0462, P0463 fuel level sensor

Description

The fuel level sensor is mounted in the fuel level sensor unit.

The sensor detects a fuel level in the fuel tank and transmits a signal to the

combination meter. The combination

me ...

Other materials:

Difference between predicted and actual distances

The displayed guidelines and their locations on

the ground are for approximate reference only.

Objects on uphill or downhill surfaces or projecting

objects will be actually located at distances

different from those displayed in the monitor relative

to the guidelines (refer to illustrations). ...

Microphone signal circuit

Description

Voice signals are transmitted from the microphone to the AV control unit

using the microphone signal circuits.

Diagnosis Procedure

1.CHECK HARNESS BETWEEN AV CONTROL UNIT AND MICROPHONE

Turn ignition switch OFF.

Disconnect AV control unit connector and microphone connector ...

Precaution

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as "AIR BAG" and "SEAT BELT

PRE-TENSIONER", used along

with a front seat belt, helps to reduce the risk or severity of injury to ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0061