Nissan Maxima Service and Repair Manual: ECM branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

-

Turn the ignition switch OFF.

-

Disconnect the battery cable from the negative terminal.

-

Check the following terminals and connectors for damage, bend and loose connection (unit side and connector side).

Models without automatic drive positioner

-

ECM

-

Harness connector E30

-

Harness connector M1

Models with automatic drive positioner

-

ECM

-

Harness connector E29

-

Harness connector B10

2.CHECK HARNESS FOR OPEN CIRCUIT

-

Disconnect the connector of ECM.

-

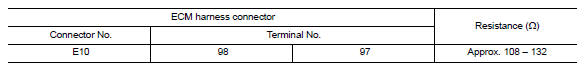

Check the resistance between the ECM harness connector terminals.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ECM. Refer to EC-157, "Diagnosis Procedure".

Is the inspection result normal?

Main line between A-bag and ABS circuit

Main line between A-bag and ABS circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative

terminal.

Check the following terminals ...

ADP branch line circuit

ADP branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative

terminal.

Check the following terminals ...

Other materials:

Fuel efficient driving tips

Follow these easy-to-use Fuel Efficient Driving

Tips to help you achieve the most fuel economy

from your vehicle.

1. Use Smooth Accelerator and Brake

Pedal Application

Avoid rapid starts and stops.

Use smooth, gentle accelerator and

brake application whenever possible.

Maintain constan ...

P0448 evap canister vent control valve

Description

The EVAP canister vent control valve is located on the EVAP canister

and is used to seal the canister vent.

This solenoid valve responds to signals from the ECM. When the

ECM sends an ON signal, the coil in the solenoid valve is energized.

A plunger will then move to seal ...

Change intervals

The oil and oil filter change intervals for your

engine are based on the use of the specified

quality oils and filters. Using engine oil and filters

that are not of the specified quality, or exceeding

recommended oil and filter change intervals

could reduce engine life. Damage to the engine

ca ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0104