Nissan Maxima Service and Repair Manual: Headlamp

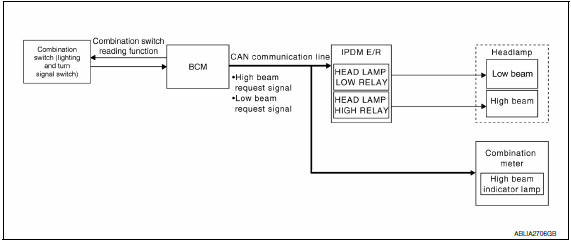

System Diagram

System Description

Control of the headlamp system operation is dependent upon the position of the combination switch (lighting and turn signal switch). When the lighting switch is placed in the 2nd position, the BCM (body control module) receives input requesting the headlamps and park lamps to illuminate. This input is communicated to the IPDM E/R (intelligent power distribution module engine room) across the CAN communication lines. The CPU (central processing unit) of the IPDM E/R controls the headlamp high and headlamp low relay coils. When energized, these relays direct power to the respective headlamps, which then illuminate.

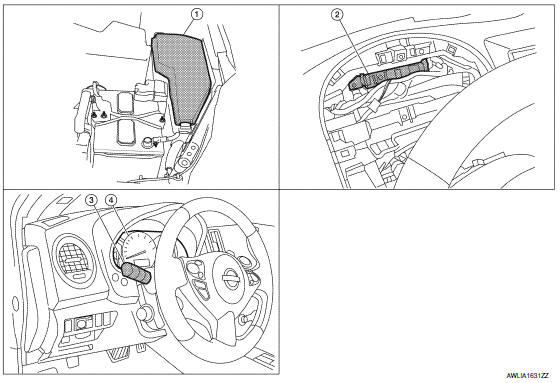

Component Parts Location

- IPDM E/R E17, E18, E200

- BCM M16, M17, M18, M19 (view with combination meter removed)

- Combination switch (lighting and turn signal switch) M28

- Combination meter M24

Component Description

LOW BEAM OPERATION

When the lighting switch is in 2ND position, the BCM receives input requesting the headlamps to illuminate.

This input is communicated to the IPDM E/R across the CAN communication lines. The CPU of the IPDM E/R controls the headlamp low relay coil which supplies power to the low beam headlamps.

HIGH BEAM OPERATION/FLASH-TO-PASS OPERATION

With the lighting switch in the 2ND position and placed in HIGH position, the BCM receives input requesting the headlamp high beams to illuminate. The flash-to-pass feature can be used any time and also sends a signal to the BCM. This input is communicated to the IPDM E/R across the CAN communication lines. The CPU of the combination meter controls the ON/OFF status off the HIGH BEAM indicator. The CPU of the IPDM E/R controls the headlamp high relay coil which supplies power to the high beam headlamps.

The combination meter receives a high beam request signal (ON) through the CAN communication lines and turns the high beam indicator lamp ON.

EXTERIOR LAMP BATTERY SAVER CONTROL

With the lighting switch (combination switch) in the 2nd position and the ignition switch is turned from ON or ACC to OFF, the battery saver feature is activated.

Under this condition, the headlamps remain illuminated for 5 minutes unless the lighting switch position is changed. If the lighting switch position is changed, then the headlamps are turned off.

This setting can be changed by CONSULT. Refer to EXL-193, "BATTERY SAVER : CONSULT Function (BCM - BATTERY SAVER)".

Daytime running light system

Daytime running light system

System Diagram

System Description

The headlamp system for Canada vehicles is equipped with a daytime light

relay that activates the high beam headlamps at approximately half

illumination whene ...

Other materials:

Oil Seal

Removal and Installation of Valve Oil Seal

REMOVAL

Turn crankshaft until the cylinder requiring new oil seals is at

TDC. This will prevent valve from dropping into cylinder.

CAUTION: When rotating crankshaft, be

careful to avoid scarring the front cover with the timing chain.

Remove ...

P0444, P0445 evap canister purge volume control solenoid

valve

Description

The EVAP canister purge volume control solenoid valve is used to

control the flow rate of fuel vapor from the EVAP canister. The EVAP

canister purge volume control solenoid valve is moved by ON/OFF

pulses from the ECM. The longer the ON pulse, the greater the

amount of fuel ...

Valet hand-off

When you have to leave a key with a valet, give

them the Intelligent Key itself and keep the mechanical

key with you to protect your belongings.

To prevent the glove box and the trunk from being

opened during valet hand-off, follow the procedures

below.

1. Push the trunk cancel switch to t ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0072