Nissan Maxima Service and Repair Manual: Headlamp aiming adjustment

Description

PREPARATION BEFORE ADJUSTING

CAUTION: Do not use organic solvent (thinner, gasoline etc.)

NOTE:

- For details, refer to the regulations in your own country.

- Perform aiming adjustment if the vehicle front body has been repaired and/or the front combination lamp assembly has been replaced.

Before performing aiming adjustment, check the following.

- Keep all tires inflated to correct pressure.

- Place vehicle on level ground.

- See that the vehicle is unloaded (except for full levels of coolant, engine oil and fuel, and spare tire, jack, and tools). Have the driver or equivalent weight placed in drivers seat.

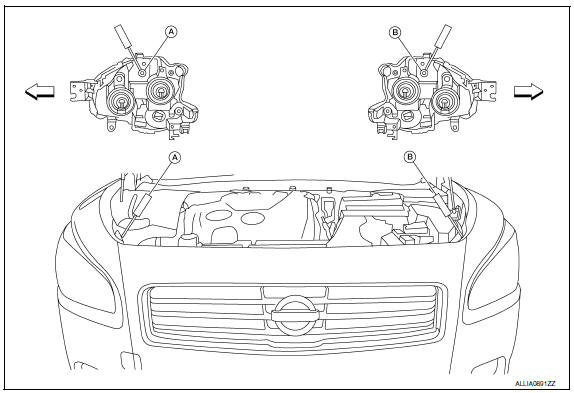

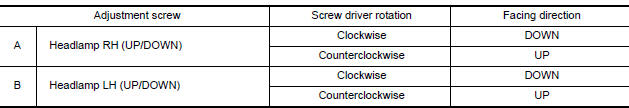

AIMING ADJUSTMENT SCREW

- Headlamp RH (UP/DOWN) adjustment screw

- Headlamp LH (UP/DOWN) adjustment screw

Vehicle center

Vehicle center

Aiming Adjustment Procedure

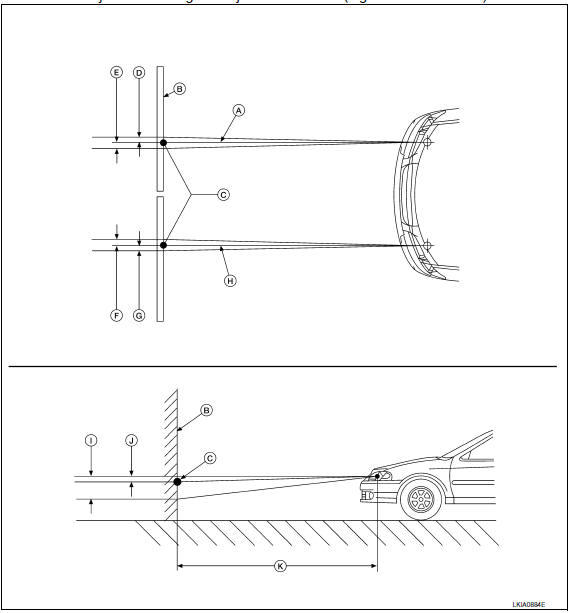

NOTE: Set the screen so that it is perpendicular to the road.

- Position the screen.

- Make the distance between the headlamp center and the screen 7.62 m (25 ft.).

- Start the engine and illuminate the headlamp (LO). CAUTION: Do not cover the lens surface with tape, etc. because it is made of plastic. NOTE: Block the light from the headlamp that is not being adjusted with a thick fabric or similar object, so that it does not reach the screen.

- Use the adjustment screw to adjust the low beams on the screen, so that it is within the aiming adjustment area.

Adjustment Using An Adjustment Screen (Light/Dark Borderline)

- Headlamp beam (RH)

- Screen

- Horizontal/Vertical center point of headlamp

- 66.5 mm (2.6 in)

- 66.5 mm (2.6 in)

- 66.5 mm (2.6 in)

- 66.5 mm (2.6 in)

- Headlamp beam (LH)

- 53.2 mm (2.1 in)

- 13.3 mm (0.5 in)

- 7.62 m (25 ft)

Front fog lamp aiming adjustment

Front fog lamp aiming adjustment

Description

PREPARATION BEFORE ADJUSTING

CAUTION: Do not use organic solvent

(thinner, gasoline etc.).

NOTE: For

details, refer to the regulations in your own country.

Before performing

aimi ...

Other materials:

BCM branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative

terminal.

Check the terminals and connectors of the BCM

for damage, bend and loose connection (unit side and

connector side).

2. ...

The low washer fluid warning continues displaying, or does not display

Description

The warning is still displayed even after

washer fluid is added.

The warning is not displayed even though the

washer tank is empty.

Diagnosis Procedure

1.CHECK WASHER FLUID LEVEL SWITCH SIGNAL CIRCUIT

Check the washer fluid level switch signal cir ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as "AIR BAG" and "SEAT BELT PRE-TENSIONER",

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0062