Nissan Maxima Service and Repair Manual: Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

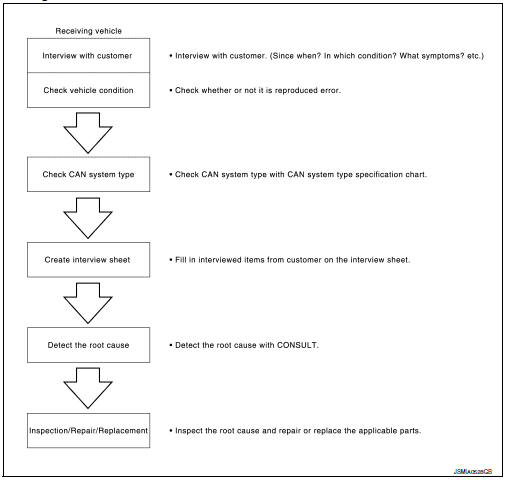

Trouble Diagnosis Flow Chart

Trouble Diagnosis Procedure

INTERVIEW WITH CUSTOMER Interview with the customer is important to detect the root cause of CAN communication system errors and to understand vehicle condition and symptoms for proper trouble diagnosis.

Points in interview

- What: Parts name, system name

- When: Date, Frequency

- Where: Road condition, Place

- In what condition: Driving condition/environment

- Result: Symptom

NOTE:

- Check normal units as well as error symptoms.

- Example: Circuit between ECM and the combination meter is judged normal if the customer indicates tachometer functions normally.

- When a CAN communication system error is present, multiple control units may malfunction or go into failsafe mode.

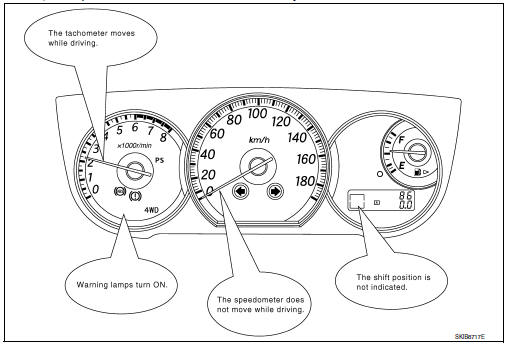

Indication of the combination meter is important to detect the root cause because it is the most obvious to the customer, and it performs CAN communication with many units.

INSPECTION OF VEHICLE CONDITION Check whether the symptom is reproduced or not.

NOTE: Do not turn the ignition switch OFF or disconnect the battery cable while reproducing the error. The error may temporarily correct itself, making it difficult to determine the root cause.

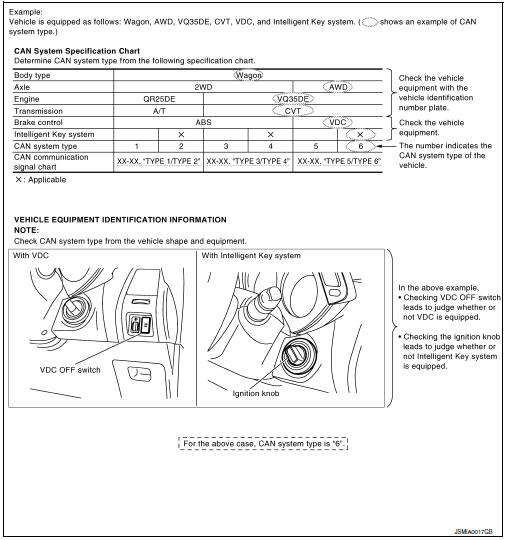

CHECK OF CAN SYSTEM TYPE (HOW TO USE CAN SYSTEM TYPE SPECIFICATION CHART) Determine CAN system type based on vehicle equipment.

NOTE:

- This chart is used if CONSULT does not automatically recognize CAN system type.

- There are two styles for CAN system type specification charts. Depending on

the number of available system types, either style A or style B may be used.

CAN System Type Specification Chart (Style A)

NOTE:

CAN system type is easily checked with the vehicle equipment identification information shown in the chart.

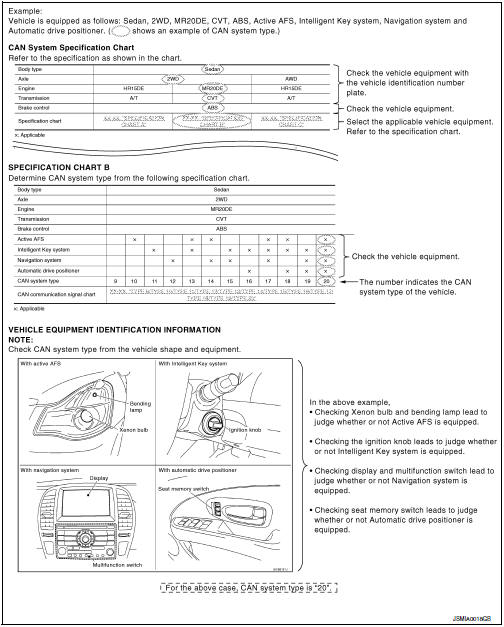

CAN System Type Specification Chart (Style B)

NOTE:

CAN system type is easily checked with the vehicle equipment identification information shown in the chart.

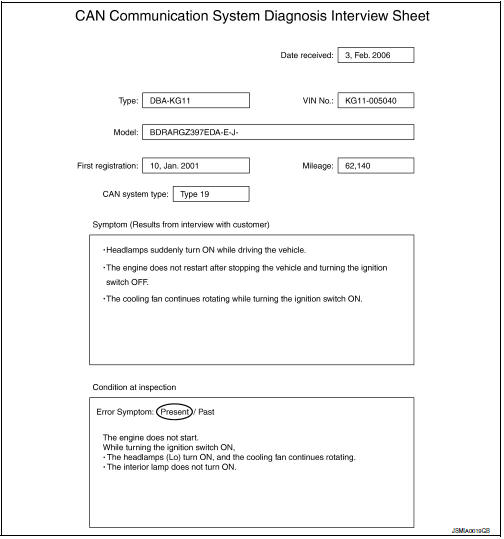

CREATE INTERVIEW SHEET

Fill out the symptom described by the customer, vehicle condition, and CAN system type on the interview sheet.

Interview Sheet (Example)

DETECT THE ROOT CAUSE CAN diagnosis function of CONSULT detects the root cause.

Trouble diagnosis

Trouble diagnosis

Condition of Error Detection

DTC (e.g. U1000 and U1001) of CAN communication is indicated on SELF-DIAG

RESULTS on CONSULT if a

CAN communication signal is not transmitted or received between unit ...

How to use this manual

How to use this manual

HOW TO USE THIS SECTION

Caution

This section describes information peculiar to a vehicle and inspection

procedures.

For trouble diagnosis procedure, refer to LAN-15, "Trouble Diagnosis

Proc ...

Other materials:

B2190 nats antenna AMP.

Description

Performs ID verification through BCM and Intelligent Key

when push-button ignition switch is pressed.

Prohibits the start of engine when an unregistered ID of Intelligent Key is

used.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCED ...

Disassembly and assembly

FUEL LEVEL SENSOR UNIT

Disassembly and Assembly

Fuel Level Sensor Unit

Harness connectors

Fuel level sensor unit

Fuel tank temperature sensor

Float arm assembly

Disassembly

NOTE: Before disassembly, note the proper

placement of the wires to the correct terminals a ...

Seats

WARNING

Do not ride in a moving vehicle when

the seatback is reclined. This can be

dangerous. The shoulder belt will not

be against your body. In an accident,

you could be thrown into it and receive

neck or other serious injuries. You

could also slide under the lap belt and

recei ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0068