Nissan Maxima Service and Repair Manual: Fuel level sensor signal circuit

Description

The fuel level sensor unit and fuel pump (fuel level sensor) detects the approximate fuel level in the fuel tank and transmits the fuel level signal to the combination meter.

Component Function Check

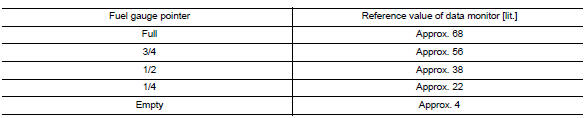

1.COMBINATION METER INPUT SIGNAL

-

Select "METER/M&A" on CONSULT.

-

Using "FUEL METER" of "DATA MONITOR", compare the value of DATA MONITOR with fuel gauge pointer of combination meter.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to MWI-87, "Wiring Diagram".

1.CHECK HARNESS CONNECTOR

-

Turn ignition switch OFF.

-

Check combination meter and fuel level sensor unit and fuel pump (fuel level sensor) terminals (meterside and harness-side) for poor connection.

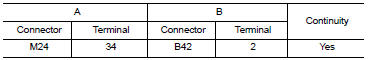

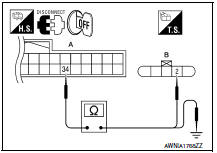

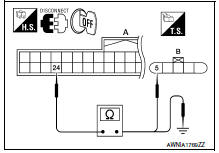

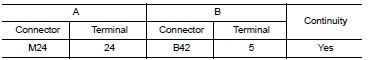

2.CHECK FUEL LEVEL SENSOR UNIT AND FUEL PUMP (FUEL LEVEL SENSOR) CIRCUIT

-

Disconnect combination meter connector and fuel level sensor unit and fuel pump (fuel level sensor) connector.

-

Check continuity between combination meter harness connector (A) and fuel level sensor unit and fuel pump (fuel level sensor) harness connector (B).

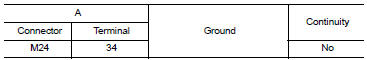

3. Check continuity between combination meter harness connector (A) and ground.

3.CHECK FUEL LEVEL SENSOR UNIT AND FUEL PUMP (FUEL LEVEL SENSOR) GROUND CIRCUIT

1. Check continuity between combination meter harness connector (A) and fuel level sensor unit and fuel pump (fuel level sensor) harness connector (B).

2. Check continuity between combination meter harness connector (A) and ground.

4.CHECK INSTALLATION CONDITION

Check fuel level sensor unit and fuel pump (fuel level sensor) installation, and check whether the float arm interferes or binds with any of the internal components in the fuel tank.

Component Inspection

1.REMOVE FUEL LEVEL SENSOR UNIT AND FUEL PUMP (FUEL LEVEL SENSOR)

Remove the fuel level sensor unit and fuel pump (fuel level sensor). Refer to FL-6, "Removal and Installation".

>> GO TO 2

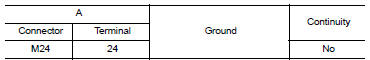

2.CHECK FUEL LEVEL SENSOR UNIT AND FUEL PUMP (FUEL LEVEL SENSOR)

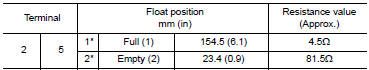

Check the resistance between terminals 2 and 5.

1* and 2*: When float arm is in contact with stopper.

Power supply and ground circuit

Power supply and ground circuit

COMBINATION METER

COMBINATION METER : Diagnosis Procedure

Regarding Wiring Diagram information, refer to MWI-87, "Wiring Diagram".

1.CHECK FUSES

Check for blown combination meter fuses.

2.POWER ...

Oil pressure switch signal circuit

Oil pressure switch signal circuit

Description

Detects the engine oil pressure and transmits the oil

pressure switch signal to the IPDM E/R.

Component Function Check

1.COMBINATION METER INPUT SIGNAL

Select "METER/M&am ...

Other materials:

Front combination lamp

Exploded View

Front combination lam

Removal and Installation

FRONT COMBINATION LAMP

Removal

Remove the front bumper fascia. Refer to EXT-16, "Removal and

Installation".

Remove the front combination lamp bolts.

Remove the harness clips from the front combination lamp assembly.

...

Combination switch system symptoms

SYMPTOM DIAGNOSIS

COMBINATION SWITCH SYSTEM SYMPTOMS

Symptom Table

Perform the data monitor of CONSULT to check for any malfunctioning

item.

Check the malfunction combinations

Identify the malfunctioning part from the agreed combination and repair

or replace the part.

...

Telescopic switch

Description

ADP steering switch (telescopic switch) is equipped to the steering column.

The operation signal is input to the automatic drive positioner control unit

when the telescopic switch is operated.

Component Function Check

1. CHECK FUNCTION

Select "TELESCO SW-FR", "TELESCO SW-RR" i ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0082