Nissan Maxima Service and Repair Manual: Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

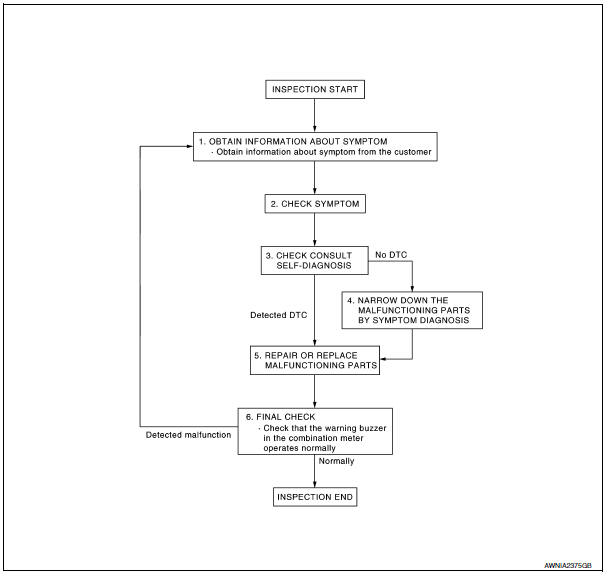

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2

2.CHECK SYMPTOM

- Check the symptom based on the information obtained from the customer.

- Check to see if any other malfunctions are present.

>> GO TO 3

3.CHECK CONSULT SELF-DIAGNOSIS RESULTS

Connect CONSULT and perform "SELF-DIAGNOSIS". Refer to MWI-29, "CONSULT Function (METER/ M&A)".

4.NARROW DOWN MALFUNCTIONING PARTS THROUGH SYMPTOM DIAGNOSIS

Perform symptom diagnosis and repair or replace the identified malfunctioning parts.

>> GO TO 5

5.REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace malfunctioning parts.

NOTE:

If DTC is displayed, erase DTC after repairing or replacing malfunctioning parts.

>> GO TO 6

6.FINAL CHECK

Check that the warning buzzer in the combination meter operates normally.

Other materials:

P1612 chain of ECM-IMMU

Description

BCM performs the ID verification with ECM that allows the

engine to start. Start the engine if the ID is OK.

ECM prevents the engine from starting if the ID is not registered. BCM starts

the communication with ECM if

ignition switch is turned ON.

DTC Logic

DTC DETECTION LOGIC ...

CVT system

System Diagram

Component Parts Location

CVT shift selector assembly (Manual

mode select switch and manual

mode position select switch)

Secondary speed sensor

CVT unit harness connector

TCM

Accelerator pedal position (APP)

sensor

Stop ...

Precaution

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and

"SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as "AIR BAG" and "SEAT BELT

PRE-TENSIONER", used along with a front seat belt, helps to reduce the risk

or severity of injury to the driver and front ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0076