Nissan Maxima Service and Repair Manual: Diagnosis and repair workflow

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

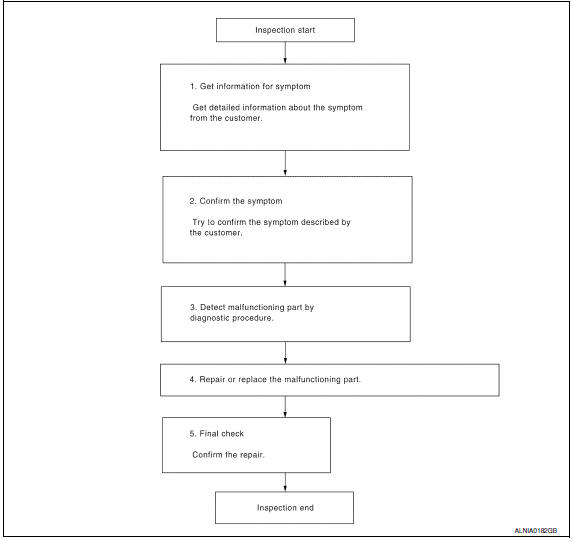

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get detailed information from the customer about the symptom (the condition and the environment when the incident/malfunction occurred).

2.CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer. Verify relation between the symptom and the condition when the symptom is detected.

3.DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the system.

4.REPAIR OR REPLACE THE MALFUNCTIONING PART

- Repair or replace the malfunctioning part.

- Reconnect parts or connectors disconnected during Diagnostic Procedure.

5.FINAL CHECK

Refer to confirmed symptom in step 2, and make sure that the symptom is not detected.

Audio system

Audio system

SYSTEM DESCRIPTION

AUDIO SYSTEM

System Diagram

System Description

AUDIO SYSTEM

The audio system consists of the following components

Audio unit

Display unit

Bluetooth control unit

W ...

Other materials:

Suspension ARM

Removal and Installation

Removal

Remove the rear suspension member. Refer to RSU-16, "Removal and

Installation".

Remove the connecting rod mount bracket nut and bolt from the rear

suspension arm using power tools.Remove the connecting rod mount

bracket.

Remove each rear suspension ...

Bose speaker AMP

Removal and Installation

Bose speaker amp.

Screws

REMOVAL

NOTE: If removing the BOSE speaker amp.

bracket, it is necessary to remove the parcel shelf finisher. The BOSE

speaker amp. can be removed without removing the BOSE speaker amp. bracket.

Disconnect the battery negative ...

Seat belt maintenance

To clean the seat belt webbing, apply a

mild soap solution or any solution recommended

for cleaning upholstery or carpet.

Then wipe with a cloth and allow the seat

belts to dry in the shade. Do not allow the

seat belts to retract until they are completely

dry.

If dirt builds up in ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0063