Nissan Maxima Service and Repair Manual: Exhaust Manifold And Three Way Catalyst

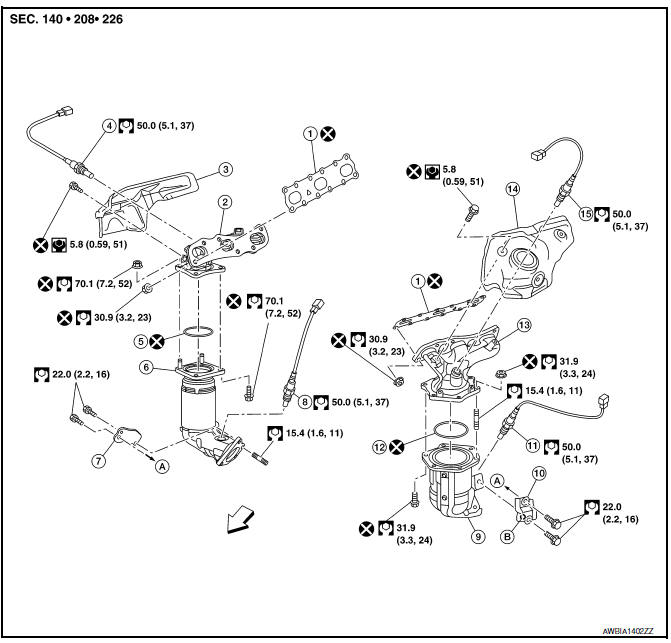

Exploded View

- Gasket

- Exhaust manifold (RH)

- Exhaust manifold heat shield (RH)

- Air fuel ratio sensor 1 (bank 1)

- Ring gasket

- Three way catalyst (bank 1)

- Three way catalyst support (bank 1)

- Heated oxygen sensor 2 (bank 1)

- Three way catalyst (bank 2)

- Three way catalyst support (bank 2)

- Heated oxygen sensor 2 (bank 2)

- Ring gasket

- Exhaust manifold (LH)

- Exhaust manifold heat shield (LH)

- Air fuel ratio sensor 1 (bank 2)

- To oil pan (upper)

- Upper mark

Engine front

Engine front

Removal and Installation (LH)

REMOVAL

WARNING:

- Perform the work when the exhaust system has completely cooled down.

- When removing the front and rear engine mounting through bolts and nuts, lift the engine up slightly for safety.

NOTE: When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

- Remove the air cleaner case assembly, and air duct hose and resonator assembly. Refer to EM-24, "Removal and Installation".

- Remove the battery and battery tray assembly. Refer to PG-68, "Removal and Installation (Battery Tray)".

- Remove the radiator. Refer to CO-14, "Removal and Installation".

- Remove the fan shroud and fan motor. Refer to CO-16, "Removal and Installation".

- Remove the front exhaust tube. Refer to EX-5, "Exploded View".

- Remove the three way catalyst support brackets (LH).

- Remove heated oxygen sensor 2 (bank 2), air fuel ratio (A/F) sensor 1 (bank 2).

- . Remove harness connector of each sensor, and disconnect the harness from the bracket and middle clamp.

- . Remove both heated oxygen sensor 2 and air fuel ratio (A/F) sensor 1 using Tool.

Tool numbers : KV10114400 (J-38365)

: KV991J0050 (J-44626)

CAUTION:

- Be careful not to damage heated oxygen sensors 2 or air fuel ratio (A/F) sensors 1.

- Discard any heated oxygen sensor 2 which has been dropped from a height of more than 0.5 m (19.7 in) onto a hard surface such as a concrete floor; replace with a new sensor.

- Remove exhaust manifold heat shield (LH) and three way catalyst heat shields (LH) using power tool.

- Remove the three way catalyst (bank 2) by loosening the bolts first and then removing the nuts and through bolts.

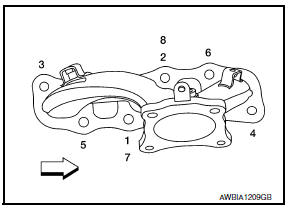

- Loosen and remove the exhaust manifold nuts in the reverse order as shown.

: Engine front

NOTE: Number 7 and 8 are not applicable to removal.

- Remove the exhaust manifold (LH) and gasket.

INSPECTION AFTER REMOVAL

Surface Distortion

- Use a suitable tool to check the flatness of the exhaust manifold mating surfaces as shown.

Limit : 0.3 mm (0.012 in)

- Replace the exhaust manifold if the measurement exceeds specifications.

INSTALLATION

Installation is in the reverse order of removal.

- Install the studs in the exhaust manifold (if removed), and tighten to specification.

Exhaust manifold studs : 15.4 N*m (1.6 kg-m, 11 ft-lb)

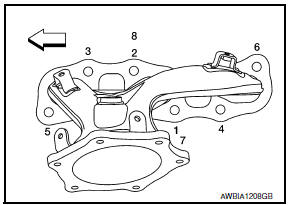

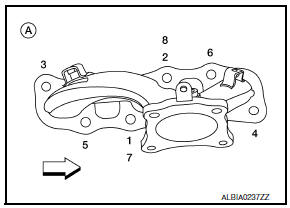

- Install the exhaust manifold gasket in the direction shown.

CAUTION: Do not reuse exhaust manifold gaskets.

(A) : Bank 1

(B) : Triangle press

(C) : Bank 2

: Engine front

: Engine front

- Install the exhaust manifold (LH) nuts and tighten to specification in the order shown.

: Engine front

: Engine front

NOTE: Number 7 and 8 are tightened a second time.

CAUTION:

- Before installing a heated oxygen sensor 2 or air fuel ratio (A/F) sensor 1, clean the exhaust manifold threads using the oxygen sensor thread cleaner tool and apply anti-seize lubricant.

Oxygen sensor thread cleaner : (J-43897-18)

Oxygen sensor thread cleaner

: (J-43897-12)

- Do not over-tighten the air fuel ratio (A/F) sensor 1 or heated oxygen sensors 2. Doing so may cause damage.

Tool numbers : KV10114400 (J-38365)

: KV991J0050 (J-44626)

Removal and Installation (RH)

REMOVAL

WARNING:

- Perform the work when the exhaust and cooling system have completely cooled down.

- When removing the front and rear engine mounting through bolts and nuts, lift the engine up slightly for safety. For engine slingers, refer to EM-103, "Removal and Installation".

- Remove the engine and transaxle assembly. Refer to EM-103, "Removal and Installation".

- Remove the (RH) three way catalyst supports.

- Remove rear engine mount bracket. Refer to EM-103, "Removal and Installation".

- Remove heated oxygen sensor 2 (bank 1), air fuel ratio (A/F) sensor 1 (bank 1).

- Remove harness connector from heated oxygen sensor 2 (bank 1) and air fuel ratio (A/F) sensor 1, and disconnect the harness from the bracket and middle clamp.

- Remove both heated oxygen sensors 2 (bank 1) and air fuel ratio (A/F) sensors 1 using Tool.

Tool numbers : KV10114400 (J-38365)

: KV991J0050 (J-44626)

CAUTION:

- Be careful not to damage heated oxygen sensors 2 or air fuel ratio (A/F) sensors 1

- Discard any heated oxygen sensor 2 which has been dropped from a height of more than 0.5 m (19.7 in) onto a hard surface such as a concrete floor; replace with a new sensor.

- Remove exhaust manifold heat shield (RH) and three way catalyst heat shields (RH) using power tool.

- Remove the three way catalyst (bank 1) by loosening the bolts first and then removing the nuts and through bolts.

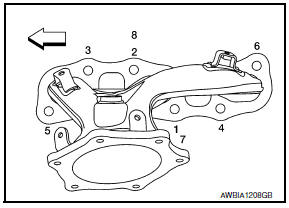

- Loosen the exhaust manifold nuts in the reverse order as shown and remove the exhaust manifold (RH).

: Engine front

: Engine front

NOTE: Number 7 and 8 are not applicable to removal.

INSPECTION AFTER REMOVAL

Surface Distortion

- Use a suitable tool to check the flatness of the exhaust manifold mating surfaces as shown.

Limit : 0.3mm (0.012 in)

INSTALLATION

Installation is in the reverse order of removal.

CAUTION: Do not reuse exhaust manifold gaskets.

- Install the exhaust manifold nuts in the order as shown (A).

:Engine front

:Engine front

NOTE: Number 7 and 8 are tightened a second time.

CAUTION:

- Before installing a heated oxygen sensor 2 or air fuel ratio (A/F) sensor 1, clean the exhaust manifold threads using the oxygen sensor thread cleaner tool, and apply anti-seize lubricant.

Tool numbers : J-43897-18

: J-43897-12

- Do not over-tighten the air fuel ratio (A/F) sensor 1 or heated oxygen sensors 2. Doing so may cause damage.

Tool numbers : KV10114400 (J-38365)

: KV991J0050 (J-44626)

Intake Manifold

Intake Manifold

Removal and Installation

Intake manifold

Intake manifold gaskets

Refer to INSTALLATION

REMOVAL

WARNING: To avoid the danger of being

scalded, do not drain the coolant when th ...

Oil Pan And Oil Strainer

Oil Pan And Oil Strainer

Exploded View

Oil pan baffle

O-ring

Gasket

Oil pressure switch

Oil cooler gasket

Oil cooler

Oil cooler connection

Oil filter

Lower oil pan

Oil strainer

Rear plate cove ...

Other materials:

Cup holders

Front cup holders

CAUTION

Avoid abrupt starting and braking when

the cup holder is being used to prevent

spilling the drink. If the liquid is hot, it

can scald you or your passenger. Spilled

liquid can also damage the seat climate

system.

Use only soft cups in the cup holder.

...

Horn function

Description

Perform answer-back for each operation with horn.

Component Function Check

1. CHECK FUNCTION

Select HORN in "ACTIVE TEST" mode with CONSULT.

Check the horn (high/low) operation.

Diagnosis Procedure

1. CHECK HORN FUNCTION

Check horn function with horn switch

2. CHECK ...

Headlamp (LO) circuit

Description

The IPDM E/R (intelligent power distribution module engine room) controls the

headlamp low relay based on inputs from the BCM over the CAN communication

lines. When the headlamp low relay is energized, power flows through fuses 51

and 52, located in the IPDM E/R. Power then flows ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0084