Nissan Maxima Service and Repair Manual: Rear Timing Chain Case

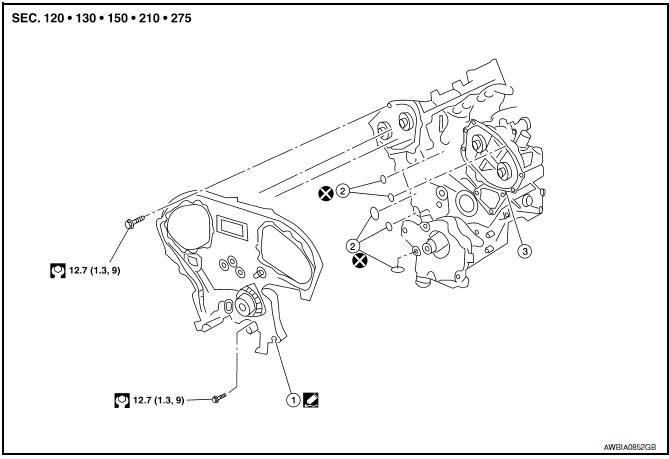

Exploded View

- Rear timing chain case

- O-ring

- Cylinder block

Removal and Installtion

CAUTION:

- After removing timing chain, do not turn the crankshaft and camshaft separately, or the valves will strike the pistons.

- Before removing the upper oil pan, remove the crankshaft position sensor (POS).

- Be careful not to damage sensor edges.

- Do not reuse O-ring.

REMOVAL

- Remove the engine assembly. Refer to EM-103, "Removal and Installation".

- Remove the oil pan lower and upper. Refer to EM-37, "Removal and Installation (Upper Oil Pan)".

- Remove the front timing chain case. Refer to EM-54, "Exploded View".

- Remove the timing chains (primary) and (secondary). Refer to EM-64, "Removal and Installation".

- Remove No. 1 camshaft bracket (RH) and No. 1 camshaft bracket (LH). Refer to EM-76, "Removal and Installation".

- Remove the rear timing chain case.

CAUTION:

- Do not remove the plate metal cover for the oil passage.

- After removing the chain case, do not apply any load to the case that might bend it.

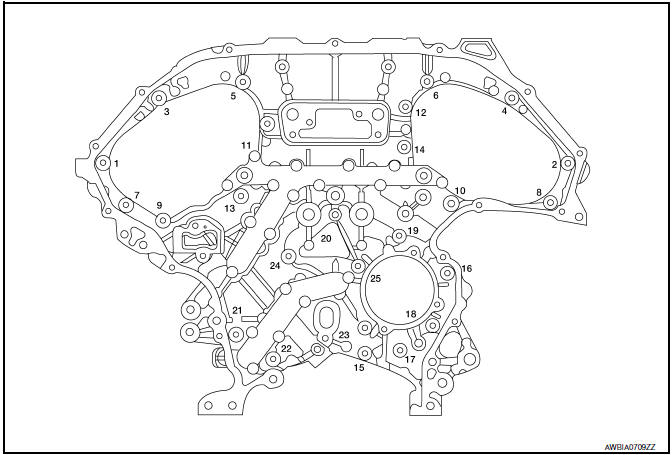

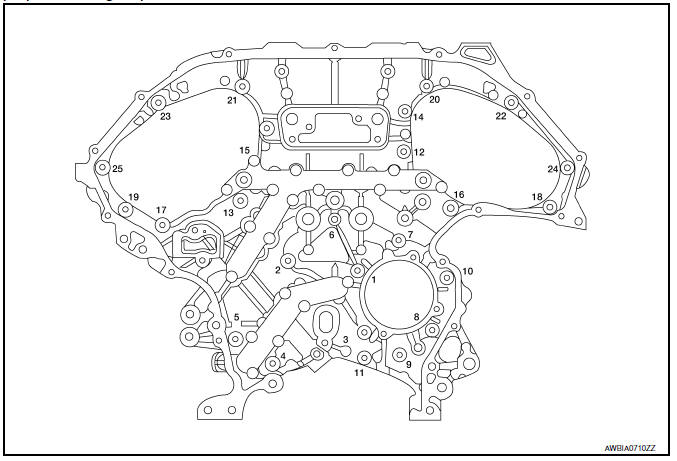

- Loosen and remove the rear timing chain case bolts in the order as shown.

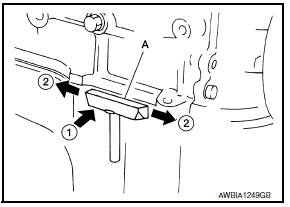

- Cut the sealant using Tool and remove the rear timing chain case.

Tool number : KV10111100 (J-37228)

CAUTION:

- Be careful not to damage the mating surface.

- Do not insert a screwdriver, this will damage the mating surfaces.

- In areas where the cutter is difficult to use, use a plastic hammer to lightly tap (1) the cutter where the liquid gasket is applied. Use a plastic hammer to slide (2) the cutter by tapping on the side.

- Remove O-rings to timing chain case and cylinder block.

CAUTION: Do not reuse O-rings.

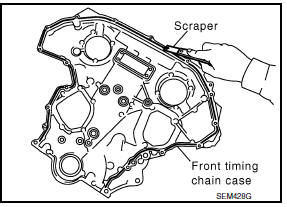

- Use a scraper to remove all of the old Silicone RTV Sealant from the front and rear timing chain case and opposite mating surfaces.

CAUTION: Do not damage the mating surfaces.

- Remove all old Silicone RTV Sealant from all the bolt holes and bolts.

CAUTION: Do not damage the threads or mating surfaces

INSTALLATION

- Install O-rings on cylinder block.

CAUTION: Do not reuse O-rings.

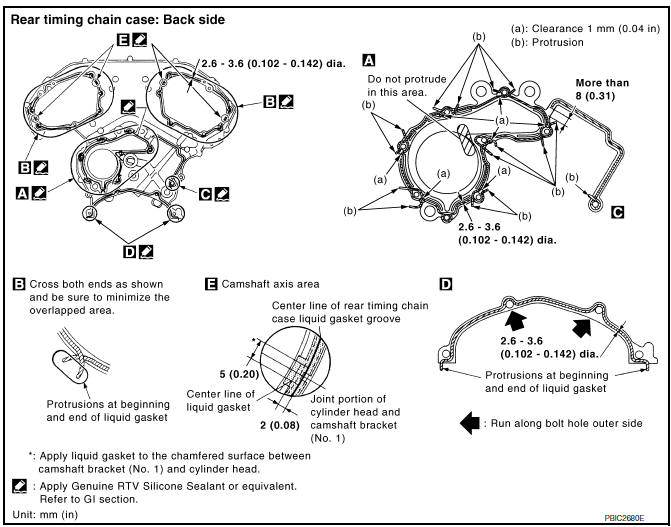

- Apply Genuine Silicone RTV Sealant or equivalent, to the rear timing

chain case using Tool as shown.

Refer to GI-21, "Recommended Chemical Products and Sealants".

Tool number : WS39930000 ( - )

CAUTION:

- For "a", completely wipe out liquid gasket extended on a portion touching at engine coolant.

- Apply liquid gasket on installation position of water pump and cylinder completely.

- Installation should be done within 5 minutes after applying liquid gasket.

- Do not fill the engine with oil for at least 30 minutes after the components are installed to allow the sealant to cure.

- Align the rear timing chain case and water pump assembly with the dowel pins (RH and LH) on the cylinder block and install the case. Make sure the O-rings stay in place during installation.

CAUTION: Do not reuse O-rings.

- Tighten the bolts in the numerical order as shown. There are two bolt lengths used. Follow the chart below for proper bolt length specifications.

- After all bolts are initially tightened, retighten them to the specification in the numerical order shown.

- Install the primary and secondary timing chains. Refer to EM-64, "Removal and Installation".

- Install the front timing chain case. Refer to EM-54, "Removal and Installation".

- Install No. 1 camshaft bracket (RH) and No. 1 camshaft bracket (LH). Refer to EM-76, "Removal and Installation".

- Install the oil pan upper and lower. Refer to EM-37, "Removal and Installation (Upper Oil Pan)".

- Install the engine assembly. Refer to EM-103, "Removal and Installation".

Timing Chain

Timing Chain

Exploded View

Timing chain tensioner (secondary)

Internal chain guide

Timing chain tensioner (secondary)

Camshaft sprocket (EXH)

Timing chain (secondary)

Timing chain (primary)

C ...

Camshaft

Camshaft

Exploded View

Camshaft position sensor bracket (RH)

Camshaft brackets

No. 1 camshaft bracket (RH)

Camshaft (EXH) (RH)

Camshaft (INT) (RH)

Cylinder head (RH)

Cylinder head (LH)

...

Other materials:

Microphone

Removal and Installation

REMOVAL

Remove the front room/map lamp assembly. Refer to INL-84, "Removal

and Installation".

Detach the microphone connector (A).

Remove the front room/map lamp covers (1), then remove the

map lamp assembly cover (2).

Release the m ...

Power supply and ground circuit

Diagnosis Procedure

1. CHECK FUSES AND FUSIBLE LINK

Check that the following IPDM E/R fuses or fusible link are not blown.

2. CHECK POWER SUPPLY CIRCUIT

Turn ignition switch OFF.

Disconnect IPDM E/R connectors.

Check voltage between IPDM E/R harness connector and ground.

3. CHE ...

Magnet clutch

Description

SYSTEM DESCRIPTION

A/C auto amp. controls A/C compressor operation by ambient temperature and

signal from ECM.

Low Temperature Protection Control

A/C auto amp. will turn the A/C compressor ON or OFF as determined

by a signal detected by ambient sensor.

When ambient temperatur ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0069