Nissan Maxima Service and Repair Manual: Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as "AIR BAG" and "SEAT BELT PRE-TENSIONER", used along with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Manual.

WARNING:

- To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

- Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag Module, see the SR section.

- Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

- When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing serious injury.

- When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution for Liquid Gasket

REMOVAL OF LIQUID GASKET

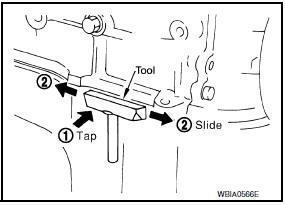

- After removing nuts and bolts, separate the mating surface using Tool and remove old liquid gasket.

Tool number : KV10111100 (J-37228)

CAUTION: Be careful not to damage the mating surfaces.

- Tap (1) Tool to insert it, and then slide it (2) by tapping on the side as shown.

- In areas where Tool is difficult to use, use plastic hammer to lightly tap the parts, to remove it.

CAUTION: If for some unavoidable reason tool such as screwdriver is used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

- Remove old liquid gasket adhering to the liquid gasket application surface and the mating surface, using scraper.

- Remove liquid gasket completely from the groove of the liquid gasket application surface, bolts, and bolt holes.

- Thoroughly clean the mating surfaces and remove adhering moisture, grease and foreign materials.

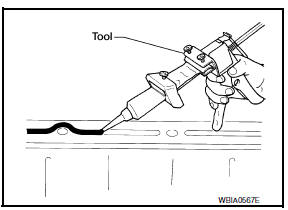

- Attach liquid gasket tube to Tool.

Tool number : WS39930000 ( - )

Use Genuine RTV Silicone Sealant or equivalent. Refer to GI-21, "Recommended Chemical Products and Sealants".

- Apply liquid gasket without breaks to the specified location with the specified dimensions.

- If there is a groove for the liquid gasket application, apply liquid gasket to the groove.

- As for the bolt holes, normally apply liquid gasket inside the holes.

Occasionally, it should be applied outside the holes.

Make sure to read the text of service manual.

- Within five minutes of liquid gasket application, install the mating component.

- If liquid gasket protrudes, wipe it off immediately.

- Do not retighten nuts or bolts after the installation.

- After 30 minutes or more have passed from the installation, fill engine oil and engine coolant.

CAUTION: Carefully follow all of the warnings, cautions, notes, and procedures contained in this manual.

Preparation

Preparation

Special Service Tool

The actual shapes of the tools may differ from those illustrated here.

Commercial Service Tool

...

Other materials:

Combination meter

Reference Value

VALUES ON THE DIAGNOSIS TOOL

NOTE:

* The monitor will indicate "OFF" even though the brake warning

lamp is on if either of the following conditions exist:

The parking brake is engaged

The brake fluid level is low

TERMINAL LAYOUT

PHYSICAL VALUES

Fail Safe

...

P014C, P014D, P014E, P014F, P015A, P015B, P015C, P015D A/F sensor

1

Description

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sensor.

The sensor element of the A/F sensor 1 is composed an electrode

layer, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the

lean ...

Transverse link

Removal and Installation

REMOVAL

Remove front wheel and tire using power tool. Refer to WT-60,

"Adjustment".

Remove the knuckle spindle bolt and nut at the transverse link.

Remove the steering knuckle from the transverse link using Tool.

Refer to FSU-13, "Exploded View".

Tool numbe ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0057