Nissan Maxima Service and Repair Manual: Door motor

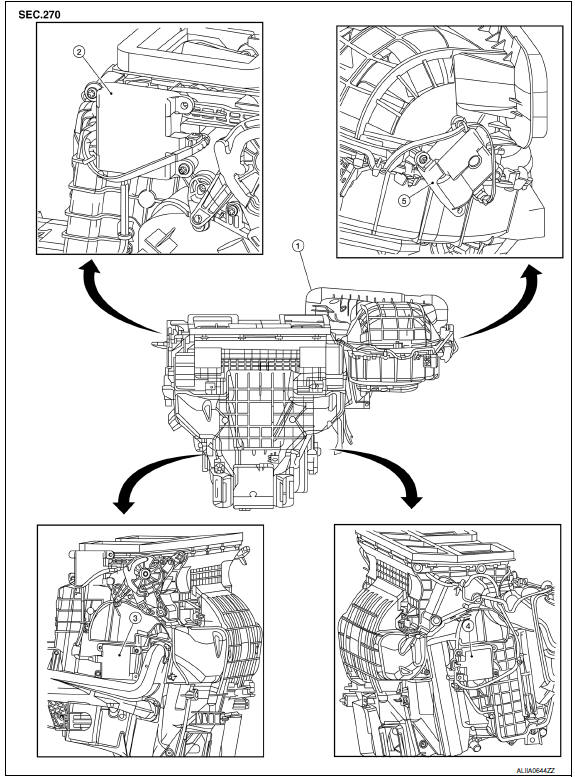

Exploded View

- Heating and cooling unit assembly

- Mode door motor

- Air mix door motor (driver side)

- Air mix door motor (passenger side)

- Intake door motor

INTAKE DOOR MOTOR

INTAKE DOOR MOTOR: Removal and Installation

REMOVAL

- Remove the glove box assembly. Refer to VTL-16, "BLOWER UNIT: Removal and Installation".

- Remove the remote keyless entry receiver and bracket to reposition out of the way.

- Disconnect the harness connector from the intake door motor.

- Remove the intake door motor screws and intake door motor from the blower unit.

INSTALLATION

Installation is in the reverse order of removal.

MODE DOOR MOTOR

MODE DOOR MOTOR: Removal and Installation

REMOVAL

- Remove the combination meter. Refer to MWI-122, "Removal and Installation".

- Remove the BCM. Refer to BCS-79, "Removal and Installation".

- Disconnect the harness connector from the mode door motor.

- Remove the mode door motor screws and the mode door motor.

INSTALLATION

Installation is in the reverse order of removal.

AIR MIX DOOR MOTOR

AIR MIX DOOR MOTOR: Removal and Installation - Air Mix Door Motor (Driver Side)

REMOVAL

- Remove the instrument lower panel LH. Refer to IP-19, "Removal and Installation".

- Remove the upper floor connecting duct (LH). Refer to HA-47, "Exploded View".

- Remove the tire pressure receiver.

- Disconnect the harness connector from the air mix door motor.

- Remove the air mix door motor screws and the air mix door motor (driver side).

INSTALLATION

Installation is in the reverse order of removal.

AIR MIX DOOR MOTOR: Removal and Installation - Air Mix Door Motor (Passenger Side)

REMOVAL

- Remove the glove box assembly. Refer to IP-19, "Removal and Installation".

- Remove the upper floor connecting duct (RH). Refer to HA-47, "Exploded View".

- Disconnect the harness connector from the air mix door motor.

- Remove the air mix door motor screws and the air mix door motor (passenger side).

INSTALLATION

Installation is in the reverse order of removal.

Refrigerant pressure sensor

Refrigerant pressure sensor

Removal and Installation

REMOVAL

Discharge the refrigerant. Refer to HA-28, "Recycle Refrigerant".

Remove the core support upper cover.

Disconnect the harness connector from the ref ...

Basic inspection

Basic inspection

INSPECTION AND ADJUSTMENT

Operational Check

DESCRIPTION

The purpose of the operational check is to check that the individual system

operates normally

Conditions: Engine running at normal operati ...

Other materials:

Low brake fluid warning light

When the ignition switch is placed in the ON

position, the light warns of a low brake fluid level.

If the light comes on while the engine is running,

with the parking brake not applied, stop the vehicle

and perform the following:

1. Check the brake fluid level. Add brake fluid

as necessary. ...

BCM (body control module)

Reference Value

NOTE: The Signal Tech II Tool (J-50190) can be used

to perform the following functions. Refer to the Signal Tech II User Guide

for additional information.

Activate and display TPMS transmitter IDs

Display tire pressure reported by the TPMS transmitter

Read TPMS DTCs

Re ...

BSW driving situations

Illustration 1 - Approaching from behind

Indicator

on

Indicator

off

Indicator

flashing

Another vehicle approaching from

behind

Illustration 1: The side BSW/RCTA indicator

light illuminates if a vehicle enters the detection

zone from behind in an adjacent lane.

Illustration 2 - ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0093