Nissan Maxima Service and Repair Manual: Variable induction air system

Description

Power Valves 1 and 2

The power valves 1 and 2 are installed in intake manifold collector and used to

control the suction passage of

the variable induction air control system. They are set in the fully closed or

fully opened position by the power

valve actuators 1 and 2 operated by the vacuum stored in the vacuum tank. The

vacuum to power valve actuators

is controlled by the VIAS control solenoid valves 1 and 2.

Component Function Check

1.CHECK OVERALL FUNCTION-I

With CONSULT

- Start engine and warm it up to the normal operating temperature.

- Perform "VIAS S/V-1" in "ACTIVE TEST" mode with CONSULT.

- Turn VIAS control solenoid valve 1 "ON" and "OFF", and check that power valve actuator 1 rod moves.

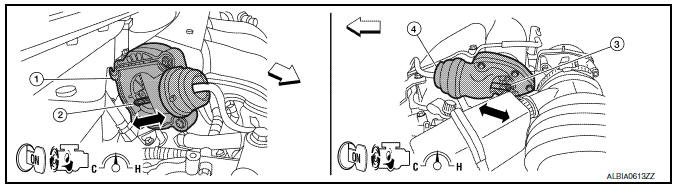

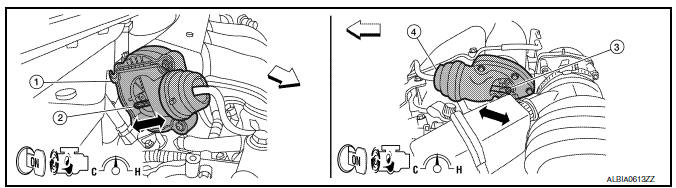

- Power valve actuator 1

- Power valve actuator 1 rod

- Power valve actuator 2 rod

- Power valve actuator 2

: Vehicle front

: Vehicle front

Without CONSULT

- Start engine and warm it up to the normal operating temperature.

- When revving engine up to 5,000 rpm quickly.

- Check that power valve actuator 1 rod moves under the following conditions.

- Power valve actuator 1

- Power valve actuator 1 rod

- Power valve actuator 2 rod

- Power valve actuator 2

: Vehicle front

: Vehicle front

2.CHECK OVERALL FUNCTION-II

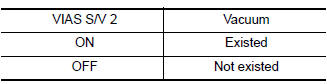

With CONSULT

- Perform "VIAS S/V-2" in "ACTIVE TEST" mode with CONSULT.

- Turn VIAS control solenoid valve 2 "ON" and "OFF", and check that power valve actuator 2 rod moves.

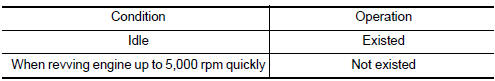

- Power valve actuator 1

- Power valve actuator 1 rod

- Power valve actuator 2 rod

- Power valve actuator 2

: Vehicle front

: Vehicle front

Without CONSULT

- When revving engine up to 5,000 rpm quickly.

- Check that power valve actuator 2 rod moves under the following conditions.

- Power valve actuator 1

- Power valve actuator 1 rod

- Power valve actuator 2 rod

- Power valve actuator 2

: Vehicle front

: Vehicle front

Diagnosis Procedure

1.INSPECTION START

Confirm the malfunctioning system (power valve 1 or power valve 2).

2.CHECK VACUUM EXISTENCE-I

With CONSULT

- Stop engine and disconnect vacuum hose connected to power valve actuator 1.

- Start engine and let it idle.

- Perform "VIAS S/V-1" in "ACTIVE TEST" mode with CONSULT.

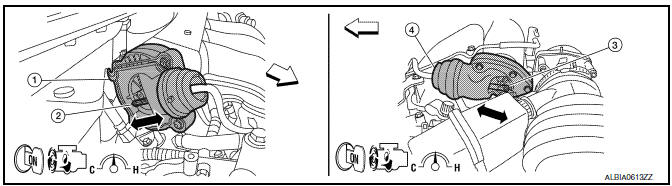

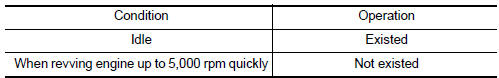

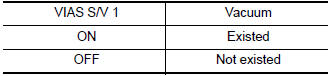

- Turn VIAS control solenoid valve 1 "ON" and "OFF", and check vacuum existence under the following conditions.

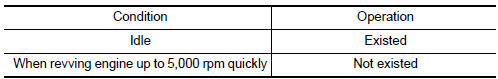

Without CONSULT

- Stop engine and disconnect vacuum hose connected to power valve actuator 1.

- Disconnect VIAS control solenoid valve 1 harness connector.

- Start engine.

- When revving engine up to 5,000 rpm quickly.

- Check vacuum existence under the following conditions.

3.CHECK VACUUM TANK

- Stop engine and disconnect vacuum hose connected to intake manifold collector.

- Start engine and let it idle.

- Check vacuum existence from intake manifold collector.

4.CHECK VACUUM HOSE

- Stop engine.

- Check vacuum hose for cracks, clogging, improper connection or disconnection.

5.CHECK VIAS CONTROL SOLENOID VALVE 1

6.CHECK VACUUM EXISTENCE-II

With CONSULT

- Stop engine and disconnect vacuum hose connected to power valve actuator 2.

- Start engine and let it idle.

- Perform "VIAS S/V-2" in "ACTIVE TEST" mode with CONSULT.

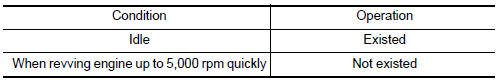

- Turn VIAS control solenoid valve 2 "ON" and "OFF", and check vacuum existence under the following conditions.

Without CONSULT

- Stop engine and disconnect vacuum hose connected to power valve actuator 2.

- Disconnect VIAS control solenoid valve 1 harness connector.

- Start engine.

- When revving engine up to 5,000 rpm quickly.

- Check vacuum existence under the following conditions.

7.CHECK VACUUM HOSE

- Stop engine.

- Check vacuum hose for cracks, clogging, improper connection or disconnection.

8.CHECK VIAS CONTROL SOLENOID VALVE 2

9.CHECK INTERMITTENT INCIDENT

Refrigerant pressure sensor

Refrigerant pressure sensor

Description

The refrigerant pressure sensor is installed at the condenser of the air

conditioner system. The sensor uses an

electrostatic volume pressure transducer to convert refrigerant pressur ...

ECU diagnosis information

ECU diagnosis information

ECM

Reference Value

VALUES ON THE DIAGNOSIS TOOL

NOTE:

The following table includes information (items) inapplicable

to this vehicle. For information (items) applicable

to this vehi ...

Other materials:

Power supply and ground circuit

Diagnosis Procedure

1. CHECK FUSES AND FUSIBLE LINK

Check that the following IPDM E/R fuses or fusible link are not blown.

2. CHECK POWER SUPPLY CIRCUIT

Turn ignition switch OFF.

Disconnect IPDM E/R connectors.

Check voltage between IPDM E/R harness connector and ground.

3. CHE ...

Reporting safety defects

For USA

If you believe that your vehicle has a defect

which could cause a crash or could

cause injury or death, you should immediately

inform the National Highway Traffic

Safety Administration (NHTSA) in addition

to notifying NISSAN.

If NHTSA receives similar complaints, it

may open an inv ...

Emission control system warranty

Your NISSAN vehicle is covered by the following

emission warranties:

For USA

1. Emission Defects Warranty

2. Emissions Performance Warranty

Details of this warranty may be found with other

vehicle warranties in your Warranty Information

Booklet which comes with your NISSAN vehicle.

If you ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0085