Nissan Maxima Service and Repair Manual: Fuel pressure

Inspection

FUEL PRESSURE RELEASE

With CONSULT

- Turn ignition switch ON.

- Perform "FUEL PRESSURE RELEASE" in "WORK SUPPORT" mode with CONSULT.

- Start engine.

- After engine stalls, crank it two or three times to release all fuel pressure.

- Turn ignition switch OFF.

Without CONSULT

- Remove fuel pump fuse located in IPDM E/R. Refer to FL-6, "Removal and Installation".

- Start engine.

- After engine stalls, crank it two or three times to release all fuel pressure.

- Turn ignition switch OFF.

- Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK

CAUTION: Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

NOTE:

- Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel pressure cannot be completely released because A35 models do not have fuel return system.

- Be careful not to scratch or get the fuel hose connection area dirty when servicing, so that the quick connector o-ring maintains seal ability.

- Use Fuel Pressure Gauge Kit [SST (J-44321)] and Fuel Pressure Adapter [SST (J-44321-6)] to check fuel pressure.

- Release fuel pressure to zero.

- Remove fuel hose using Quick Connector Release [SST (J-45488)]. Refer to FL-10, "Exploded View".

- Do not twist or kink fuel hose because it is plastic hose.

- Do not remove fuel hose (3) from quick connector.

- Keep fuel hose connections clean.

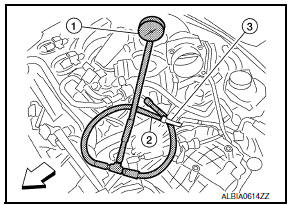

- Install Fuel Pressure Adapter [SST (J-44321-6)] (2) and Fuel Pressure Gauge kit [SST (J44321)] (1) as shown in figure.

- Do not distort or bend fuel rail tube when installing fuel pressure gauge adapter.

- When reconnecting fuel hose, check the original fuel hose for damage and abnormality.

- Turn ignition switch ON (reactivate fuel pump) and check for fuel leakage.

- Start engine and check for fuel leakage.

- Read the indication of fuel pressure gauge kit [SST (J-44321)].

- During fuel pressure check, check for fuel leakage from fuel connection every 3 minutes.

At idling : Approximately 350 kPa (3.57 kg/cm2, 51 psi)

- If result is unsatisfactory, go to next step.

- Check the following.

- Fuel hoses and fuel tubes for clogging

- Fuel filter for clogging

- Fuel pump

- Fuel pressure regulator for clogging

- If OK, replace fuel pressure regulator.

If NG, repair or replace malfunctioning part.

- Before disconnecting Fuel Pressure Gauge kit [SST (J-44321)] and Fuel Pressure Adapter [SST (J- 44321-6)], release fuel pressure to zero.

Evap leak check

Evap leak check

Inspection

CAUTION:

Never use compressed air or a high pressure pump.

Never exceed 4.12 kPa (0.042 kg/cm2, 0.6 psi) of pressure in

EVAP system.

NOTE:

Do not start en ...

Other materials:

U0100 lost communication (ECM A)

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for at

least 10 seconds, then perform the next test.

2.PERFORM DTC CONFIRMATION PROCEDURE

Start the en ...

Automatic air conditioner system

System Diagram

CONTROL SYSTEM

The control system consists of input sensors, switches, the A/C auto amp.

(microcomputer) and outputs. The

relationship of these components is as shown in the figure below:

System Description

CONTROL OPERATION

Display

The operation status of the HVAC system ...

Rear door finisher

Exploded View

Rear door finisher

Step lamp

Armrest finisher

Rear power window switch finisher

Inside release handle escutcheon

Inside release handle

Flat head screws

Screw Clip

Pawl

Front

Removal and Installation

CAUTION: Wrap the tip of a suitab ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0061