Nissan Maxima Service and Repair Manual: P0720 output speed sensor

Description

The secondary speed sensor detects the revolution of the CVT output shaft and emits a pulse signal. The pulse signal is transmitted to the TCM, which converts it into vehicle speed.

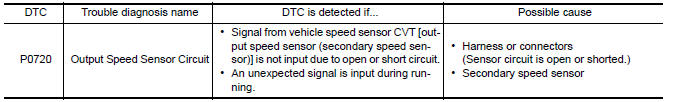

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION: Always drive vehicle at a safe speed.

NOTE: Immediately after performing any "DTC CONFIRMATION PROCEDURE", always turn ignition switch OFF.

Then wait at least 10 seconds before performing the next test.

1.CHECK DTC DETECTION

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select "Data Monitor" in "TRANSMISSION".

- Start engine and maintain the following conditions for at least 12 consecutive seconds.

ACC PEDAL OPEN : More than 1.0/8

RANGE : "D" position

Driving location : Driving the vehicle uphill (increased engine load) will help maintain the driving conditions required for this test.

With GST

With GST

Follow the procedure "With CONSULT".

Diagnosis Procedure

Regarding Wiring Diagram information, refer to TM-126, "Wiring Diagram".

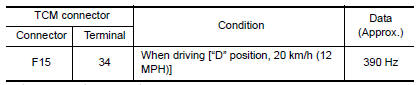

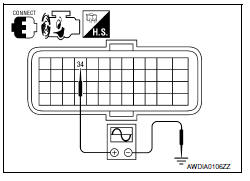

1.CHECK SECONDARY SPEED SENSOR

With CONSULT

With CONSULT

Check the pulse when vehicle drive.

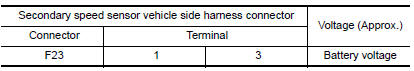

2.CHECK POWER AND SENSOR GROUND

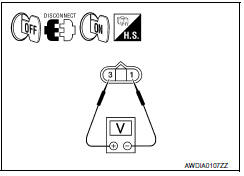

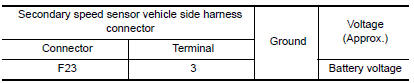

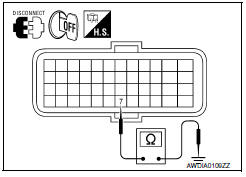

- Turn ignition switch OFF.

- Disconnect secondary speed sensor connector.

- Turn ignition switch ON.

- Check voltage between secondary speed sensor vehicle side harness connector terminals.

5. Check voltage between secondary speed sensor vehicle side harness connector terminal and ground.

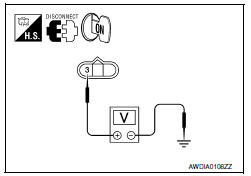

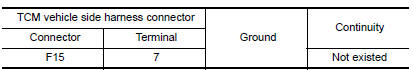

3.CHECK HARNESS BETWEEN TCM AND SECONDARY SPEED SENSOR (SENSOR GROUND)

-

Turn ignition switch OFF.

-

Disconnect TCM connector.

-

Check continuity between TCM vehicle side harness connector terminal and ground.

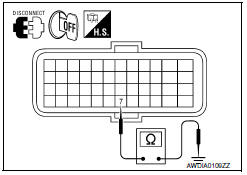

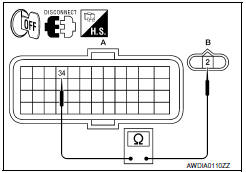

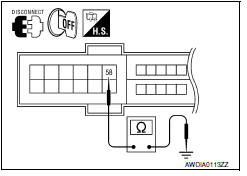

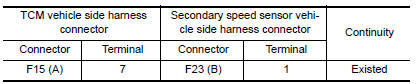

4.CHECK HARNESS BETWEEN TCM AND SECONDARY SPEED SENSOR (PART 1)

Check continuity between TCM vehicle side harness connector terminal and secondary speed sensor vehicle side harness connector terminal.

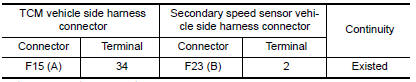

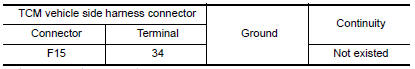

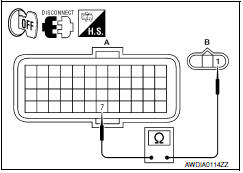

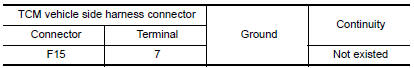

5.CHECK HARNESS BETWEEN TCM AND SECONDARY SPEED SENSOR (PART 2)

Check continuity between TCM vehicle side harness connector terminal and ground.

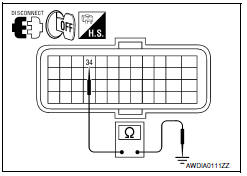

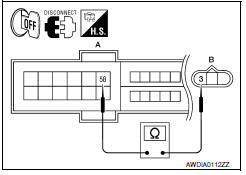

6.CHECK HARNESS BETWEEN IPDM E/R AND SECONDARY SPEED SENSOR (POWER) (PART 1)

- Turn ignition switch OFF.

- Disconnect IPDM E/R connector.

- Check continuity between IPDM E/R vehicle side harness connector terminal and secondary speed sensor vehicle side harness connector terminal.

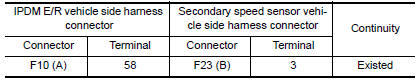

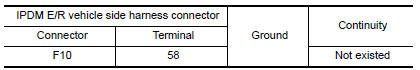

7.CHECK HARNESS BETWEEN IPDM E/R AND SECONDARY SPEED SENSOR (POWER) (PART 2)

Check continuity between IPDM E/R vehicle side harness connector terminal and ground.

8.CHECK HARNESS BETWEEN TCM AND SECONDARY SPEED SENSOR (SENSOR GROUND) (PART 1)

-

Turn ignition switch OFF.

-

Disconnect TCM connector.

-

Check continuity between TCM vehicle side harness connector terminal and secondary speed sensor vehicle side harness connector terminal.

9.CHECK HARNESS BETWEEN TCM AND SECONDARY SPEED SENSOR (SENSOR GROUND) (PART 2)

Check continuity between TCM vehicle side harness connector terminal and ground.

10.CHECK TCM

- Replace with the same type of TCM. Refer to TM-168, "Exploded View".

- Perform "DTC CONFIRMATION PROCEDURE". Refer to TM-60, "DTC Logic".

11.DETECT MALFUNCTIONING ITEMS

Check TCM connector pin terminals for damage or loose connection with harness connector.

P0715 input speed sensor A

P0715 input speed sensor A

Description

The primary speed sensor detects the primary pulley revolution speed and

sends a signal to the TCM.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always driv ...

P0725 engine speed

P0725 engine speed

Description

The engine speed signal is transmitted from ECM to TCM via CAN communication

line.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a sa ...

Other materials:

Opener operation

To open the trunk lid, push the opener switch.

To close the trunk lid, lower and push the trunk lid

down securely.

NOTE:

You can open the trunk lid with the Intelligent

Key. For additional information, refer

to "NISSAN Intelligent Key" in this section.

Cancel switch

When the cancel ...

Compass

Wiring Diagram - WITH HOMELINK UNIVERSAL TRANSCEIVER

Wiring Diagram - WITHOUT HOMELINK UNIVERSAL TRANSCEIVER

...

Vehicle speed signal circuit

Description

Combination meter sends vehicle speed signal to power steering control unit.

Diagnosis Procedure

1.PERFORM COMBINATION METER SELF-DIAGNOSIS

Perform combination meter self-diagnosis.

2.CHECK HARNESS BETWEEN COMBINATION METER AND POWER STEERING CONTROL UNIT FOR

OPEN

Turn the ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0056