Nissan Maxima Service and Repair Manual: P0744 torque converter

Description

This malfunction is detected when the torque converter clutch does not lock-up as instructed by the TCM. This is not only caused by electrical malfunctions (circuits open or shorted), but also by mechanical malfunctions such as control valve sticking, improper solenoid valve operation, etc.

DTC Logic

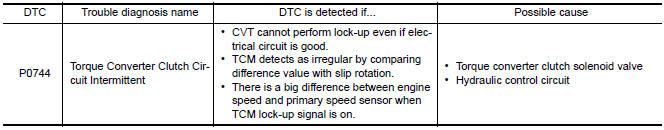

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION: Always drive vehicle at a safe speed.

NOTE: Immediately after performing any "DTC CONFIRMATION PROCEDURE", always turn ignition switch OFF.

Then wait at least 10 seconds before performing the next test.

1.CHECK DTC DETECTION

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select "Data Monitor" in "TRANSMISSION".

- Start engine and maintain the following condition for at least 30 seconds.

ACC PEDAL OPEN : More than 1.0/8

RANGE : "D" position

VEHICLE SPEED : Constant speed of more than 40 km/h (25 MPH)

With GST

With GST

Follow the procedure "With CONSULT".

Diagnosis Procedure

1.CHECK LINE PRESSURE

Perform line pressure test. Refer to TM-162, "Inspection and Judgment".

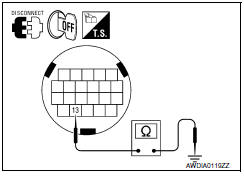

2.CHECK TORQUE CONVERTER CLUTCH SOLENOID VALVE

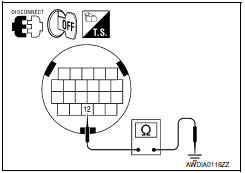

- Turn ignition switch OFF.

- Disconnect CVT unit connector.

- Check torque converter clutch solenoid valve. Refer to TM-70, "Component Inspection (Torque Converter Clutch Solenoid Valve)".

3.CHECK LOCK-UP SELECT SOLENOID VALVE

Check lock-up select solenoid valve. Refer to TM-70, "Component Inspection (Lock-up Select Solenoid Valve)".

4.CHECK SECONDARY SPEED SENSOR SYSTEM

Check secondary speed sensor system. Refer to TM-60, "DTC Logic".

5.CHECK PRIMARY SPEED SENSOR SYSTEM

Check primary speed sensor system. Refer to TM-57, "DTC Logic".

6.DETECT MALFUNCTIONING ITEMS

Check TCM connector pin terminals for damage or loose connection with harness connector.

Component Inspection (Torque Converter Clutch Solenoid Valve)

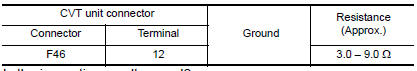

1.CHECK TORQUE CONVERTER CLUTCH SOLENOID VALVE

Check resistance between CVT unit connector terminal and ground.

Component Inspection (Lock-up Select Solenoid Valve)

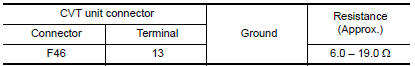

1.CHECK LOCK-UP SELECT SOLENOID VALVE

Check resistance between CVT unit connector terminal and ground.

P0740 torque converter

P0740 torque converter

Description

The torque converter clutch solenoid valve is activated by the TCM

in response to signals sent from the vehicle

speed and accelerator pedal position sensors. Lock-up piston ...

P0745 pressure control solenoid A

P0745 pressure control solenoid A

Description

The line pressure solenoid valve regulates the oil pump discharge pressure to

suit the driving condition in

response to a signal sent from the TCM.

DTC Logic

DTC DETECTION LOGIC

...

Other materials:

ECU diagnosis information

BCM (BODY CONTROL MODULE)

Reference Value

NOTE: The Signal Tech II Tool (J-50190) can be used

to perform the following functions. Refer to the Signal Tech II User Guide

for additional information.

Activate and display TPMS transmitter IDs

Display tire pressure reported by the ...

Bose speaker amp

Reference Value

TERMINAL LAYOUT

PHYSICAL VALUES

...

Power seat for passenger side

Wiring Diagram

...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0077